Chlorphenesin carbamate and preparation method thereof

A technology of chlorphenesin carbamate and chlorphenesin ether, which is applied in the preparation of carbamic acid derivatives, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of low production safety and achieve improved production safety, Simplified production process and low cost

Inactive Publication Date: 2010-10-06

ZHEJIANG JIUXU PHARMA +1

View PDF2 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, the production safety of the above-mentioned method is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

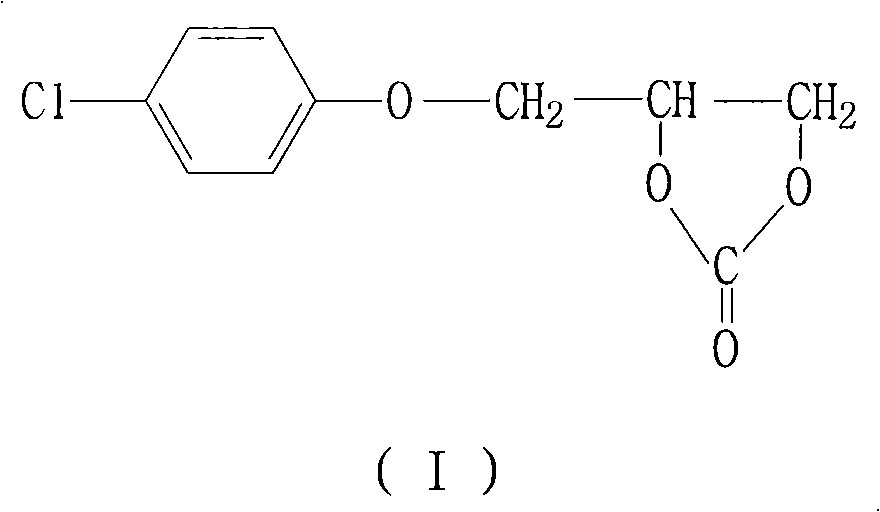

Login to View More Abstract

The invention discloses chlorphenesin carbamate and a preparation method thereof. The preparation method comprises the step of mixing a compound shown in a formula (1) with ammonium reagent and alkali in an organic solvent in the presence of water at the temperature of 0-40 DEG C. The preparation method in the invention utilizes a raw material containing ammonium ions so as to avoid using of strong pungent ammonia water, improves production safety and is favor of environment protection.

Description

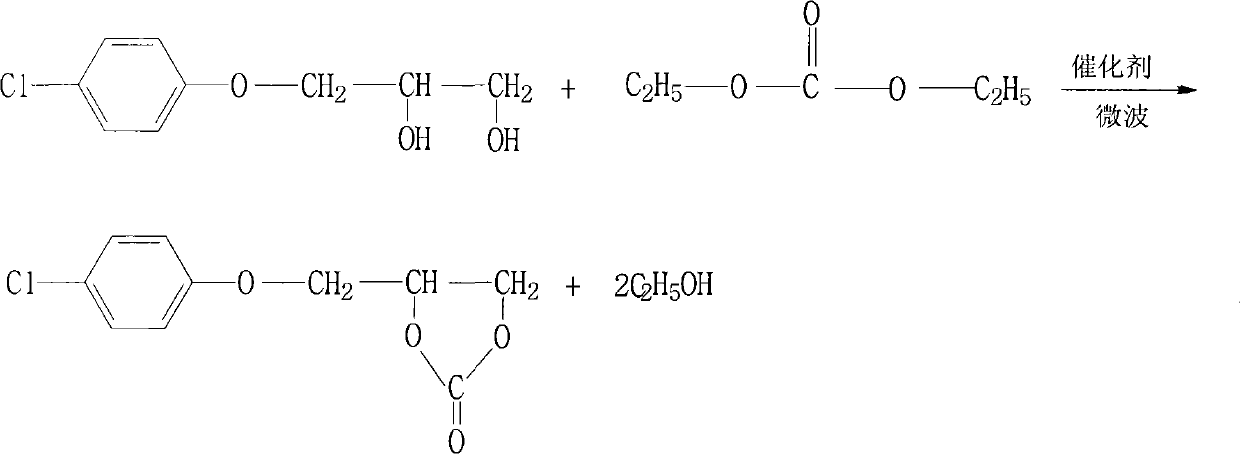

technical field The present invention relates to chlorophenyl glyceryl carbamate and preparation method thereof. Background technique Chlorphenesin Carbamate, as a muscle relaxant, has high curative effect and few side effects. At present, the synthesis route of chlorphenesin carbamate is mainly to react chlorphenesin ether with diethyl carbonate to generate a cyclic ether, which is further reacted with ammonia water to prepare chlorphenesin carbamate. Chinese patent application CN10162435 discloses a preparation method of chlorphenesin urethane, specifically, chlorphenesin reacts with diethyl carbonate under the action of a small amount of transesterification catalyst, and then adds tert-butanol, dimethylformamide and ammonia water, Chlorphenglyceryl carbamate. Owing to use ammoniacal liquor in above-mentioned synthetic route, and ammoniacal liquor is volatile, has strong irritant, has irritant to respiratory tract and skin, and damages central nervous system. If ammon...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C271/12C07C269/00

Inventor 潘自国李宏于自勋岳昌林陈美兰

Owner ZHEJIANG JIUXU PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com