Design method of constant-frequency gas-insulated X-ray flaw detector

A design method and X-ray technology, applied in the design field of constant frequency gas-insulated X-ray flaw detectors, can solve the problems of damage, large current, large X-ray scattered flash dose, etc., so as to reduce the interference of high-order harmonics, increase the The effect of large pulse width and penetration thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The design method of the constant-frequency gas-insulated X-ray flaw detector of the present invention is carried out according to the following steps:

[0016] a. The high-voltage transformer of the X-ray industrial flaw detector and the filament transformer of the X-ray tube are designed to share the same iron core;

[0017] b. Since the X-ray generator is an inductive load, it has a resonant circuit composed of distributed inductance and distributed capacitance. Therefore, the frequency of the applied voltage is adjusted to the resonant frequency of the resonant circuit, so that the X-ray generator becomes a pure resistance. sex load;

[0018] c. The tube current of the X-ray tube is stabilized by adjusting the pulse width of the applied voltage.

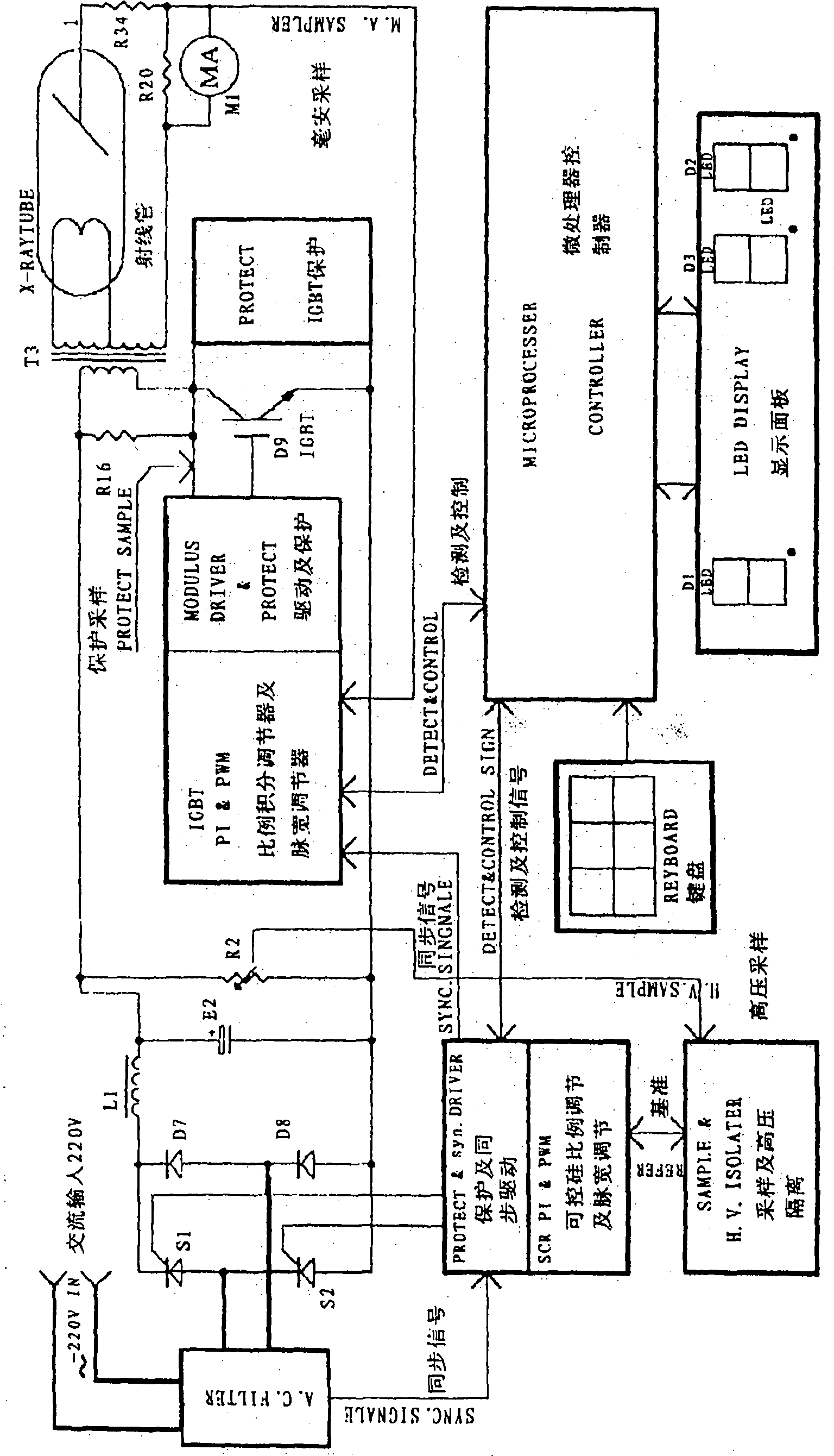

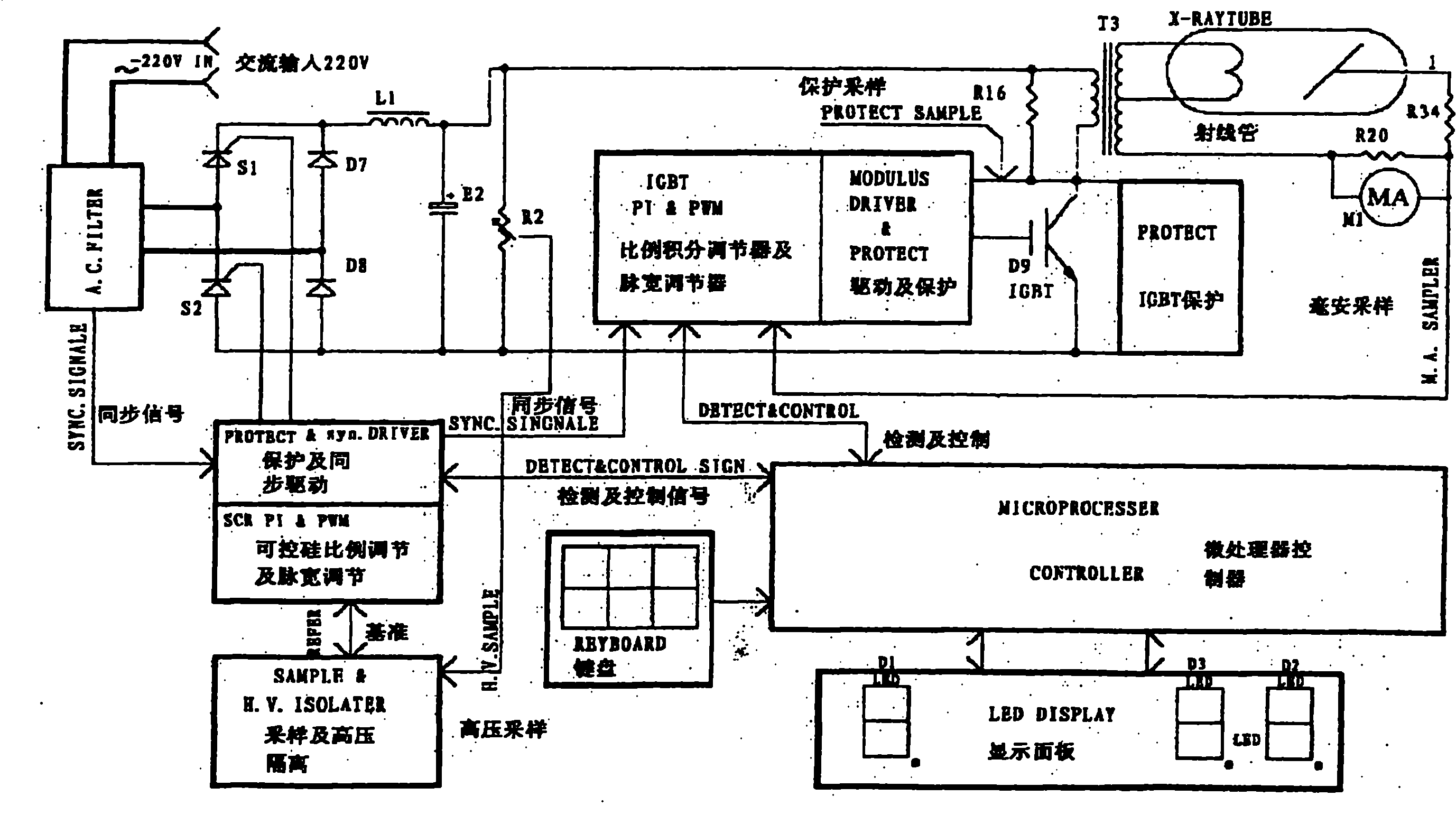

[0019] As shown in Figure 1, the following is the constant frequency gas-insulated X-ray flaw detector manufactured according to the design method of the present invention:

[0020] 1. High voltage rectification part

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap