Aircraft

An aircraft and controller technology, applied in the field of aircraft, can solve problems such as high fuel consumption, difficult landing, and low speed, and achieve the effects of improved maneuverability, low operating cost, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

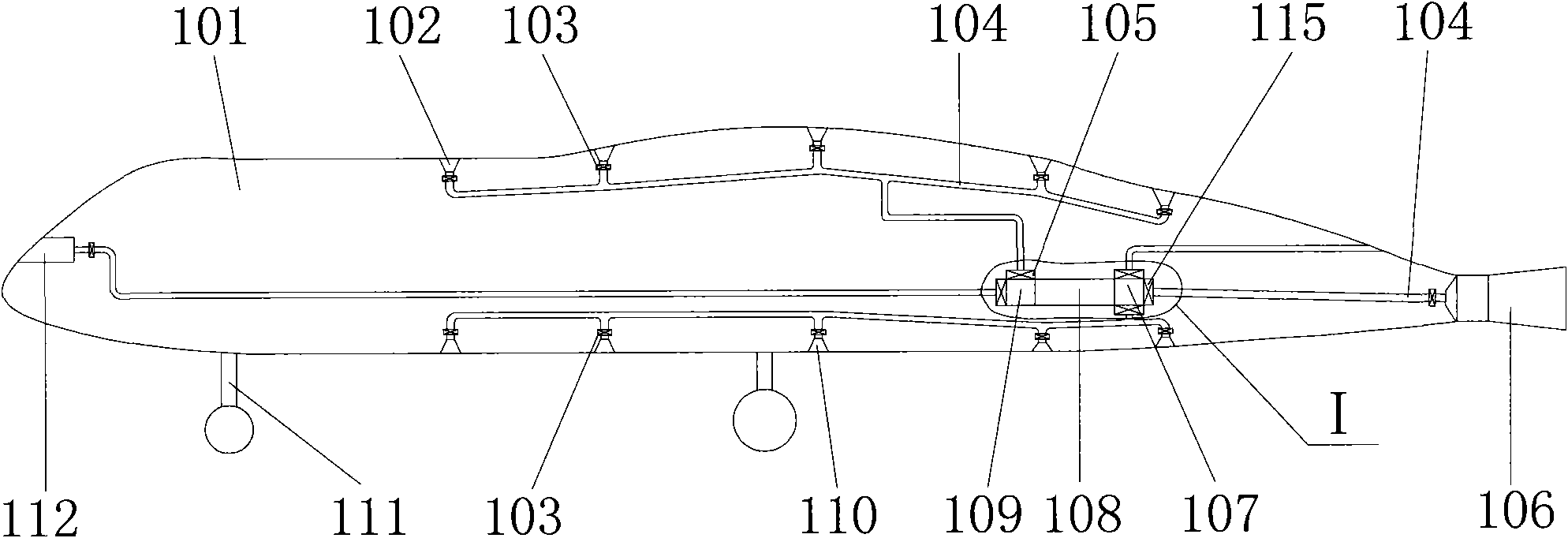

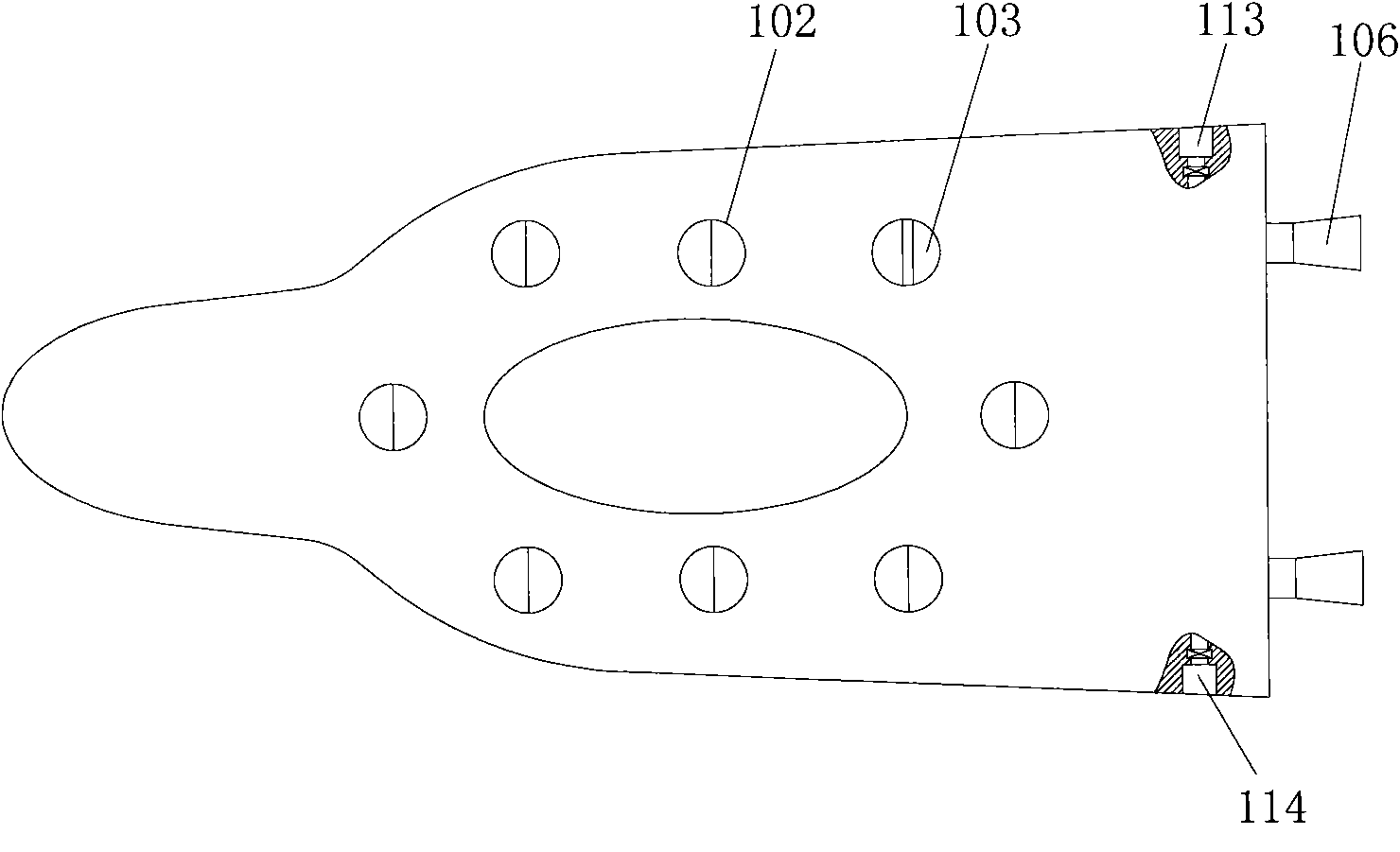

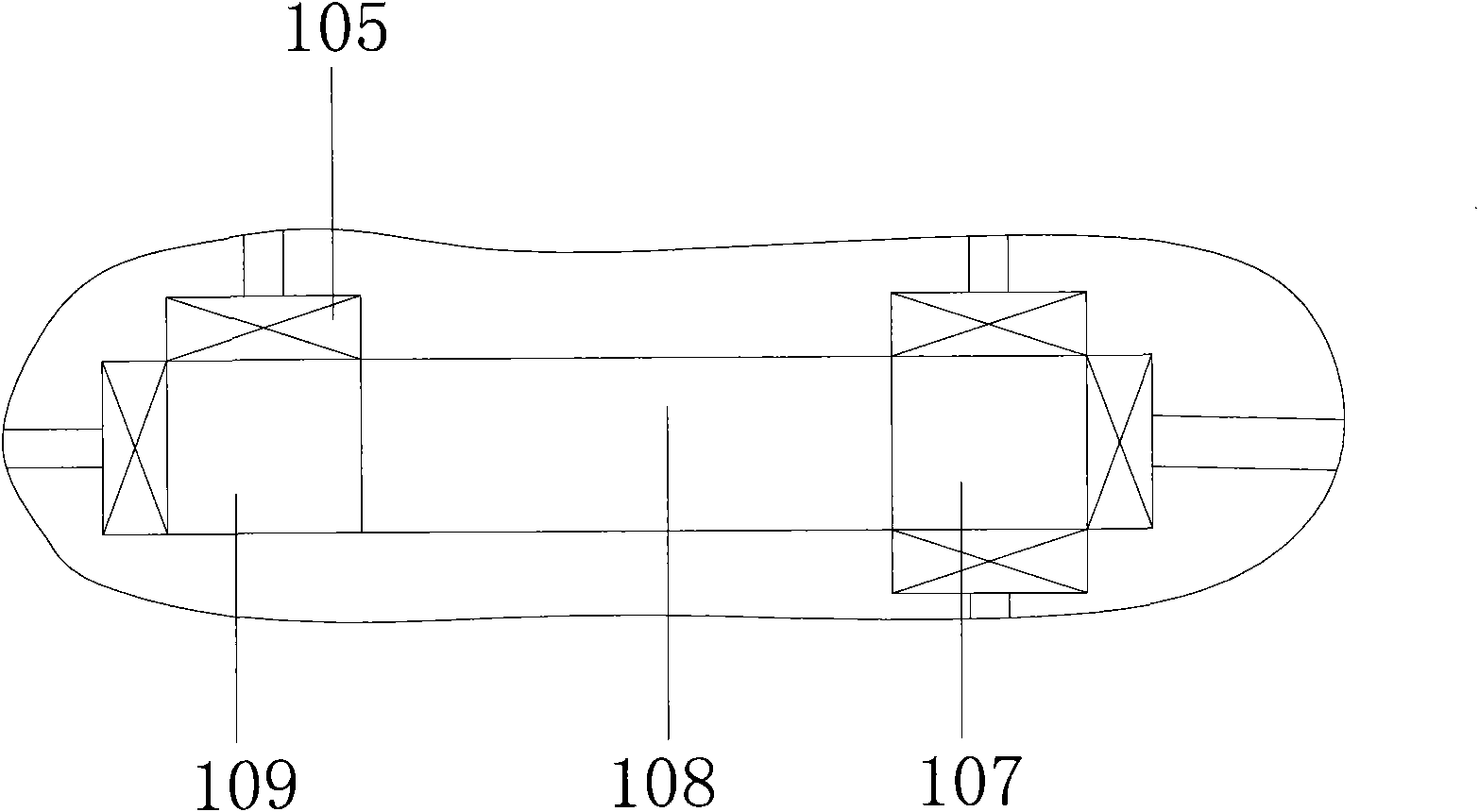

[0072] see Figure 1-Figure 3 , figure 1 It is a schematic structural diagram of the aircraft provided in Embodiment 1 of the present invention, figure 2 for figure 1 top view of image 3 for figure 1 Partial enlarged view of I.

[0073] Wherein, 101 is a fuselage, 102 is an upper air hole, 103 is an air valve, 104 is a trachea, 105 is a first gas valve device, 106 is a tail air hole, 107 is an exhaust box, 108 is an engine, and 109 is an air intake box, 110 is a lower air hole, 111 is a landing gear, 112 is a front end air hole, 113 is a right air hole, 114 is a left air hole, and 115 is a second gas valve device.

[0074] Front, back, left, right, up and down of aircraft provided by the present invention are equipped with front air hole 112, tail air hole 106, left side air hole 114, right side air hole 113, upper air hole 102, lower air hole 110 respectively. Wherein, the front air hole 112 , the left air hole 114 , the right air hole 113 , the upper air hole 102 and...

Embodiment 2

[0100] Multiple engines are installed on the aircraft to independently control the air in and out of different air holes.

[0101] as attached Figure 9 , Figure 10 , Figure 9 It is a schematic structural diagram of the aircraft provided in Embodiment 2 of the present invention, Figure 10 for Figure 9 top view.

[0102] Among them, 201 is the fuselage, 202 is the upper air hole, 3a is the air pipe, 4a is the air valve, 3b is the air pipe, 4b is the air valve, 3c is the air pipe, 4c is the air valve, 3d is the air pipe, 4d is the air valve, 3e is Air pipe, 4e is an air valve, 3f is an air pipe, 4f is an air valve, 5a is a gas valve device, 5b is a gas valve device, 206 is an air intake box, 207 is a first engine, 208 is an exhaust box, and 209 is a lower air hole , 210 is a landing gear, 211 is a front air hole, 212 is a second engine, 213 is an air distributor, 214 is a right jet hole, 215 is a right suction hole, 216 is a third engine, 217 is a tail air hole, and 218...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com