Method for preparing nano WS2/MoS2 granules

A kind of particle and nano technology, applied in the field of preparation of nano WS2 or MoS2 particles, can solve the problems of complex process, difficult to realize industrial production, high cost, etc., and achieve the effect of simple process, low product cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

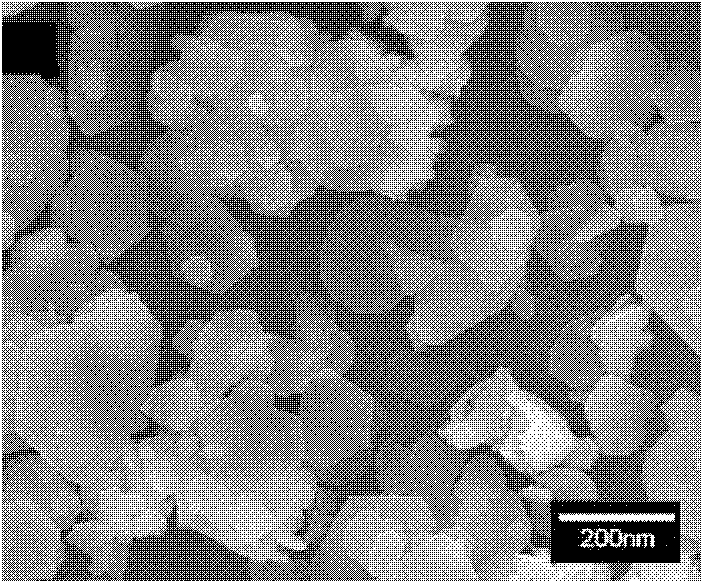

[0030] Take 5kgWS 2 Coarse powder, 50kg of zirconia grinding balls, and 25kg of deionized water are put into a rod-type ball mill, the speed of the ball mill is 200r / min, the diameter of the grinding ball is 0.8mm, and 8 ultrasonic generators with a power of 1200W are used to apply ultrasonic waves with a frequency of 20kHz. Pulverize for 6 hours, then take out the powder slurry, and dry it in a freeze dryer with a temperature of -45°C and a vacuum of 20 Pa to obtain a finished product.

[0031] The particle size analyzed by laser diffraction particle size analyzer is:

[0032] d 10 =15nm

[0033] d 50 =90nm

[0034] d 90 =260nm

[0035] Average particle size = 95nm

[0036] The scanning electron microscope photos of the particles are attached figure 1 .

Embodiment 2

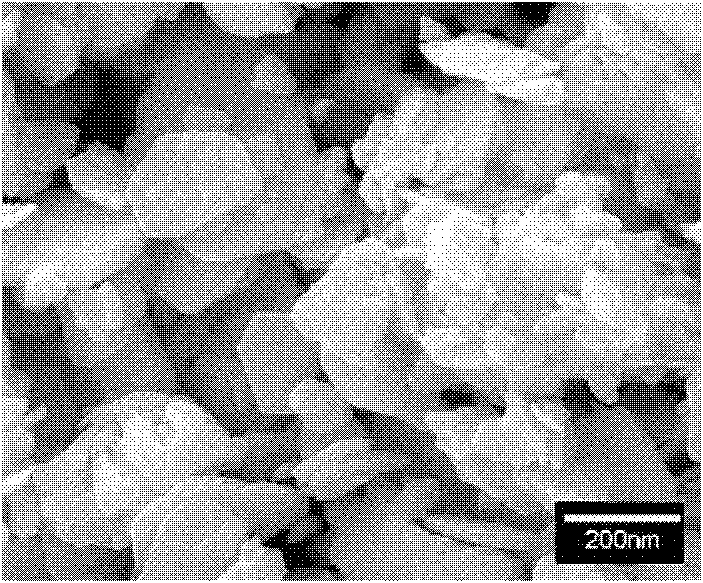

[0038] Take 4kg MoS 2 Coarse powder, 50kg zirconia balls, and 24kg deionized water are put into a rod-type ball mill, the ball mill speed is 300r / min, the diameter of the ball is 1.8mm, and 8 ultrasonic generators with a power of 800W are used to apply ultrasonic waves with a frequency of 20kHz. Pulverize for 5 hours, then take out the slurry, and dry it in a freeze dryer with a temperature of -50°C and a vacuum of 35Pa to obtain a finished product.

[0039] The particle size analyzed by laser diffraction particle size analyzer is:

[0040] d 10 =20nm;

[0041] d 50 =95nm;

[0042] d 90 = 280nm;

[0043] Average particle size = 100 nm.

[0044] The scanning electron microscope photos of the particles are attached figure 2 .

Embodiment 3

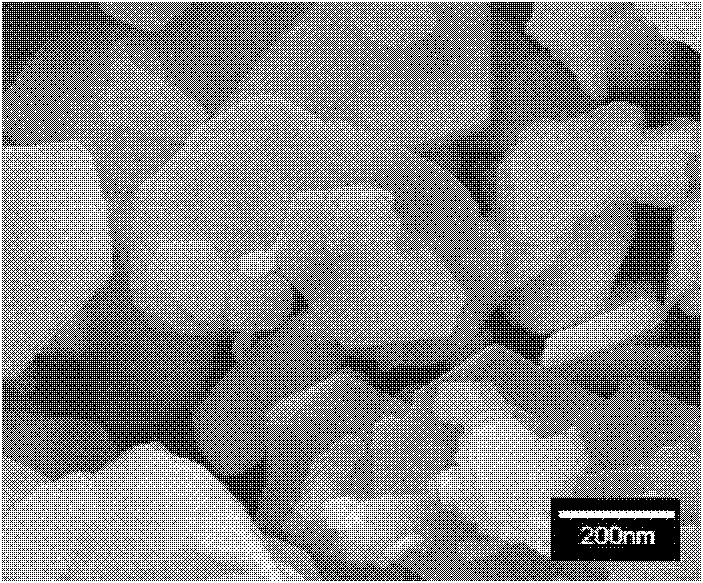

[0046] Take 5kg MoS 2 Coarse powder, 50kg of zirconia balls, and 15kg of deionized water are put into a rod-type ball mill, the speed of the ball mill is 350r / min, the diameter of the ball is 3mm, and 8 ultrasonic generators with a power of 500W are used to apply ultrasonic waves with a frequency of 20kHz, and compound wet crushing After 10 hours, the slurry was taken out and dried in a freeze dryer at a temperature of -40°C and a vacuum of 9 Pa to obtain a finished product.

[0047] The particle size analyzed by laser diffraction particle size analyzer is:

[0048] d 10 =35nm;

[0049] d 50 = 100nm;

[0050] d 90 =320nm;

[0051] Average particle size = 120 nm.

[0052] The scanning electron microscope photos of the particles are attached image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com