Polymer emulsion modified rapid repair mortar and preparation method thereof

A technology of polymer emulsion and repair mortar, which is applied in the field of building materials, can solve the problems of no literature reports and unsuitability, and achieve the effects of improving brittleness, increasing flexural strength, and increasing bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The following method is used to prepare polymeric emulsion modified quick repair mortar, and the specific method comprises the following steps:

[0031]Pour 20 kg of acrylic emulsion (18 kg of 209 emulsion, 2 kg of 510TS emulsion) and 0.1 kg of defoamer into a container and stir evenly for later use. 42.5 sulfoaluminate early-strength cement produced by the cement plant) and 2.2 kg of polypropylene fiber are dispersed evenly, and then 230 kg of quartz sand, 0.9 kg of high-efficiency water reducer, 0.15 kg of retarder, and 0.1 kg of early-strength agent are added and stirred evenly When in use, add the liquid material in the container to the prepared powder in proportion, and add about 28 kg of water to adjust the consistency of the mortar, and stir for 3 to 5 minutes to obtain the repair material.

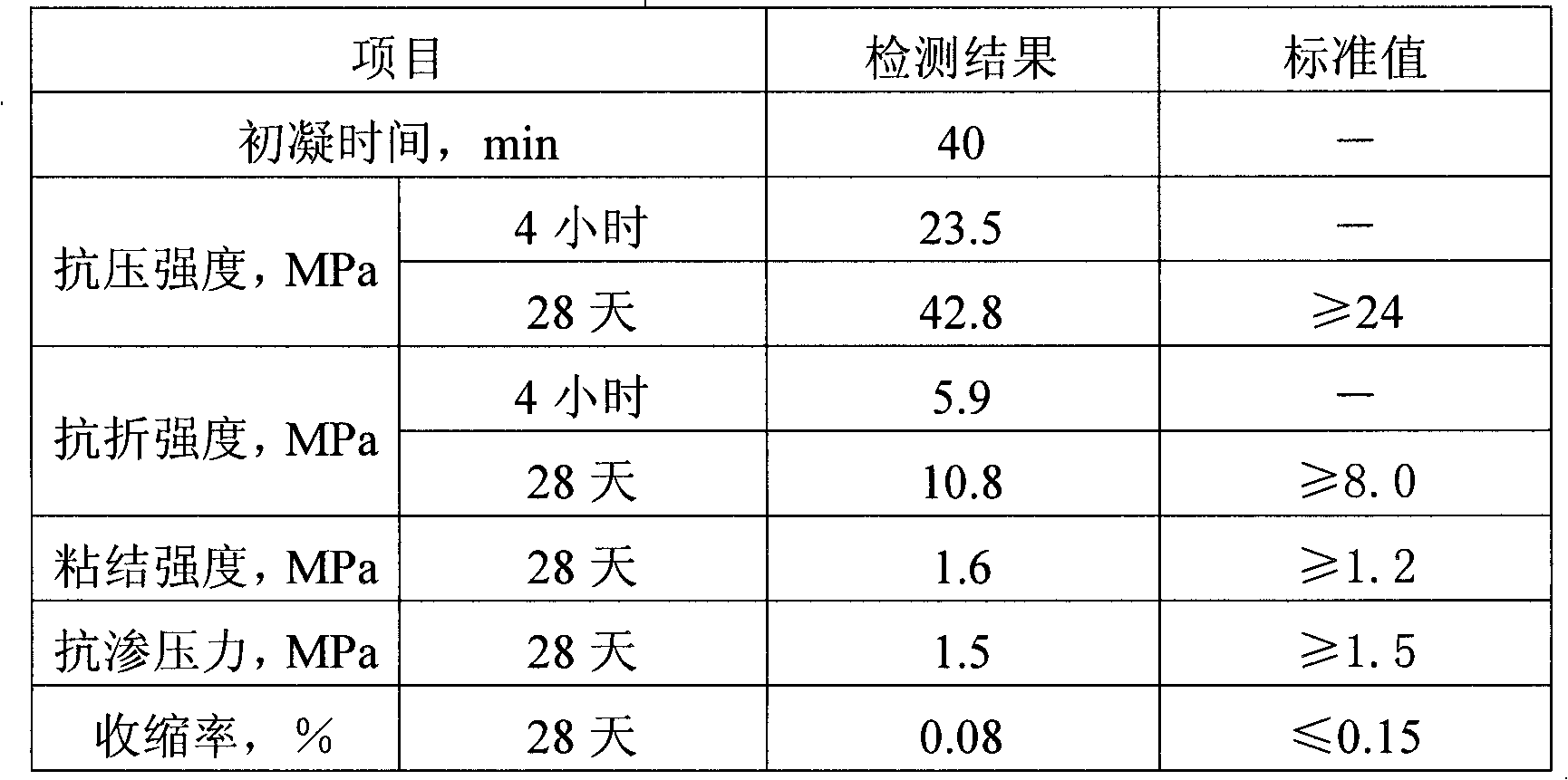

[0032] Refer to the performance testing method in "Polymer Cement Waterproof Mortar" JC / T 984-2005 to test the polymer emulsion modified quick repair mortar of the present i...

Embodiment 2~5

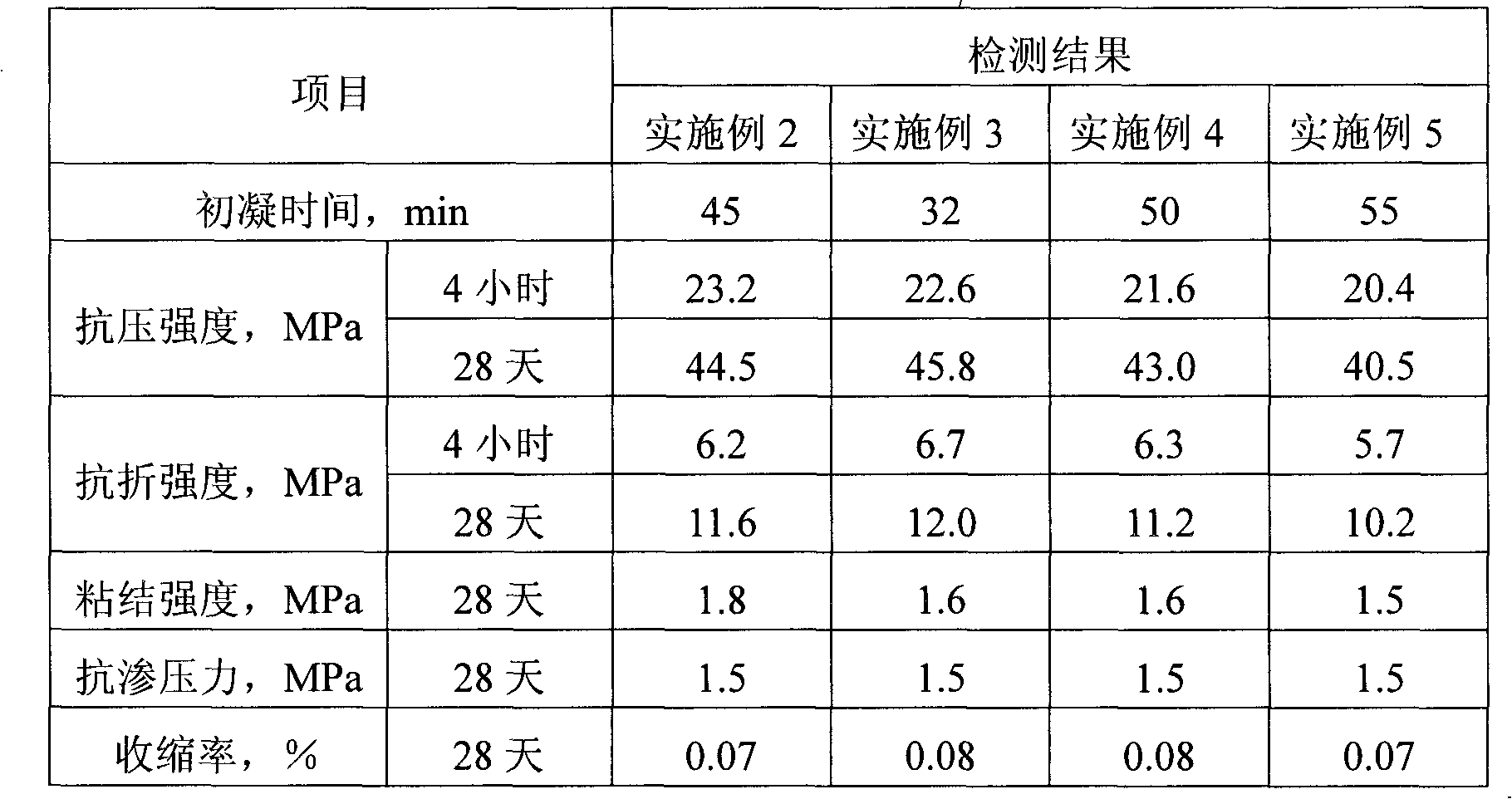

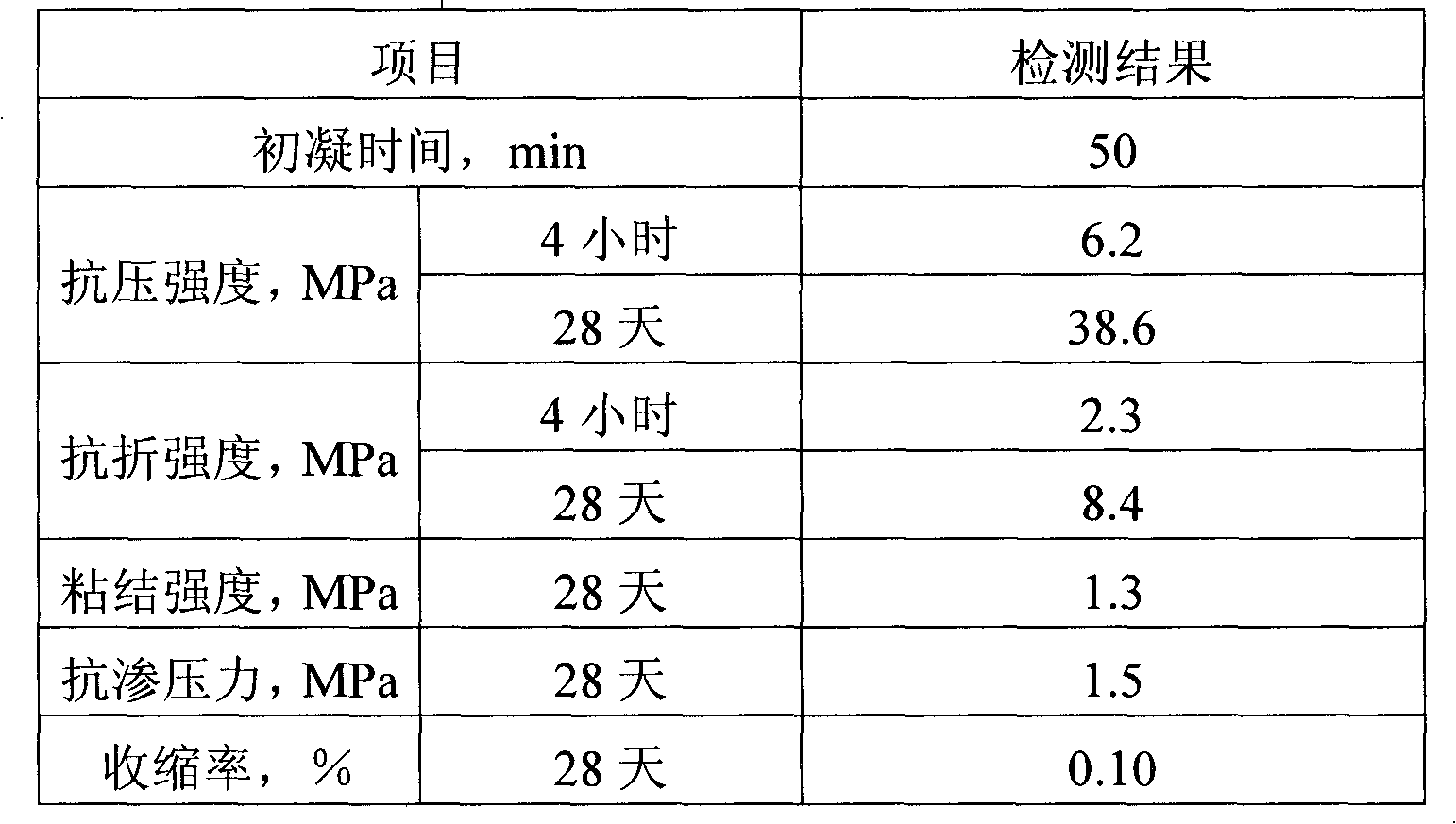

[0037] The raw materials in Table 2 were used to prepare rapid repair mortar in the same manner as in Example 1, and the test results are shown in Table 3.

[0038] Table 2 Rapid Repair Mortar Raw Materials

[0039] Raw material (kg)

Example 2

Example 3

Example 4

Example 5

Sulfur-aluminate early-strength cement

100

100

100

100

Quartz sand

250

200

250

300

0.8

1.0

1.2

0.9

0.25

0.10

0.20

0.5

early strength agent

0.2

0.15

0.05

0.18

Polypropylene fibers

2.5

2.2

2.0

2.3

209 lotion

27

18

21.6

22.5

510TS emulsion

3

2

2.4

2.5

0.12

0.15

0.12

0.1

water

26

30

20

21

[0040] Table 3 Performance testing of quick repair ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com