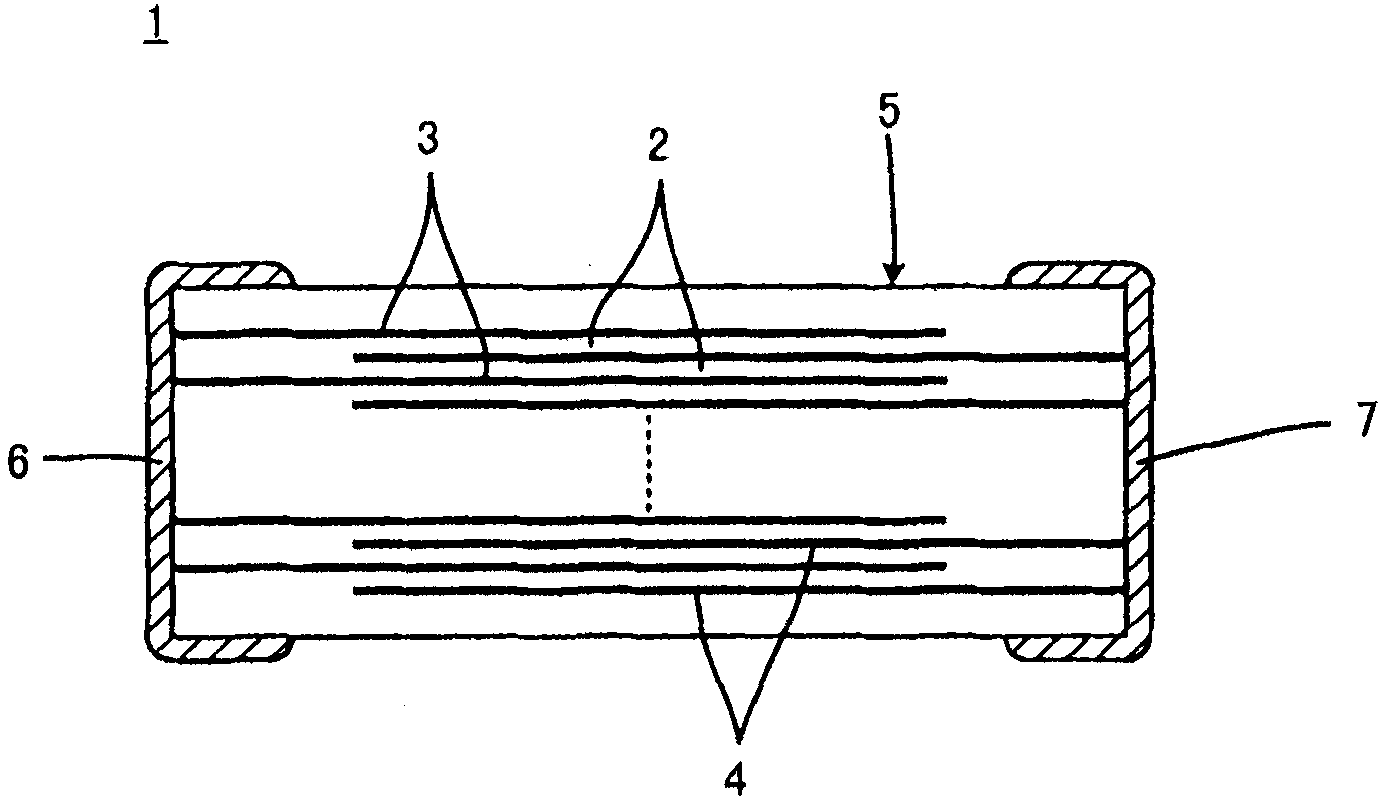

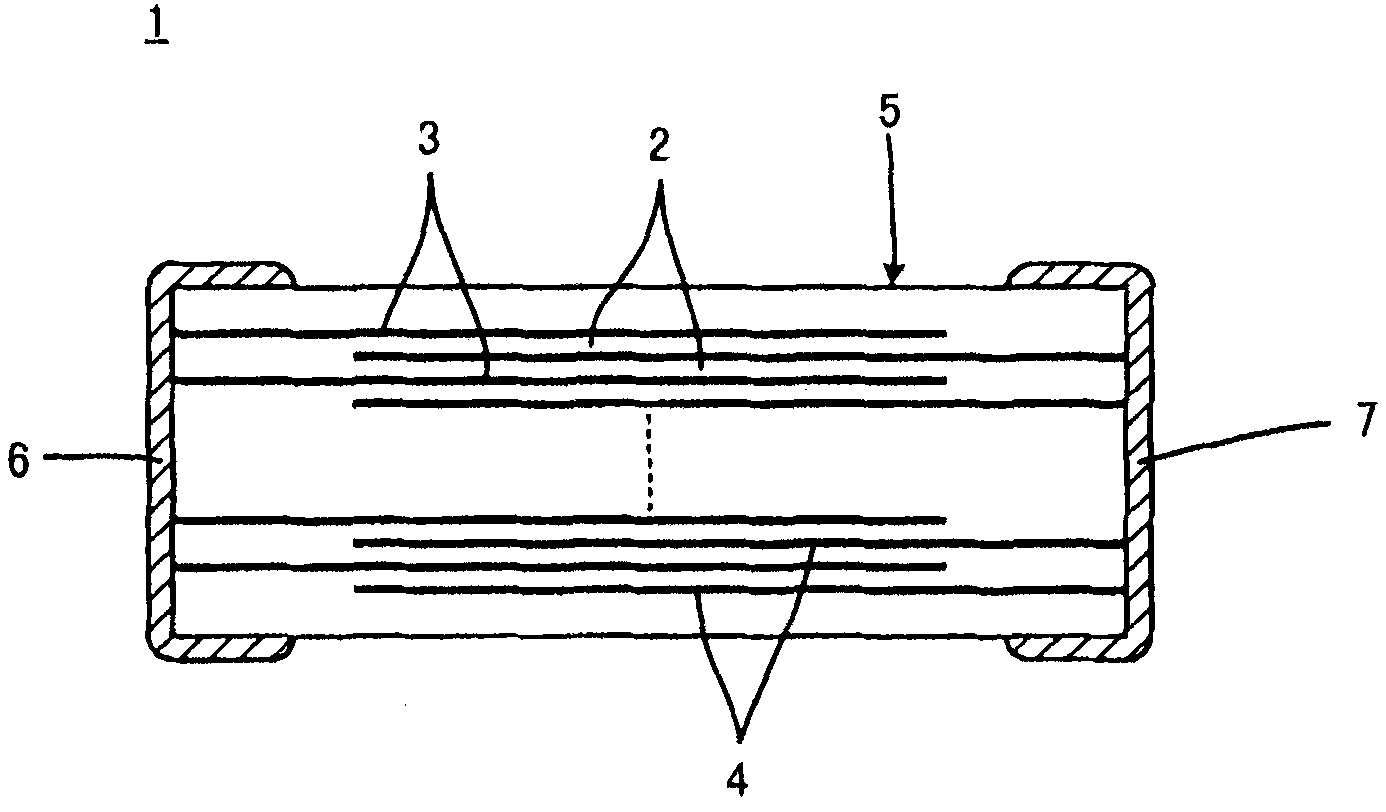

Barium titanate powder, process for producing the same, dielectric ceramic, and laminated ceramic capacitor

A technology of dielectric ceramics and barium titanate, which is applied in the field of reliability of laminated ceramic capacitors, can solve problems such as difficulty in obtaining powder with particle size deviation, frequent occurrence of short circuit defects, and decreased insulation, and achieve good crystallinity and improved fault life characteristics , the effect that the integral width becomes smaller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

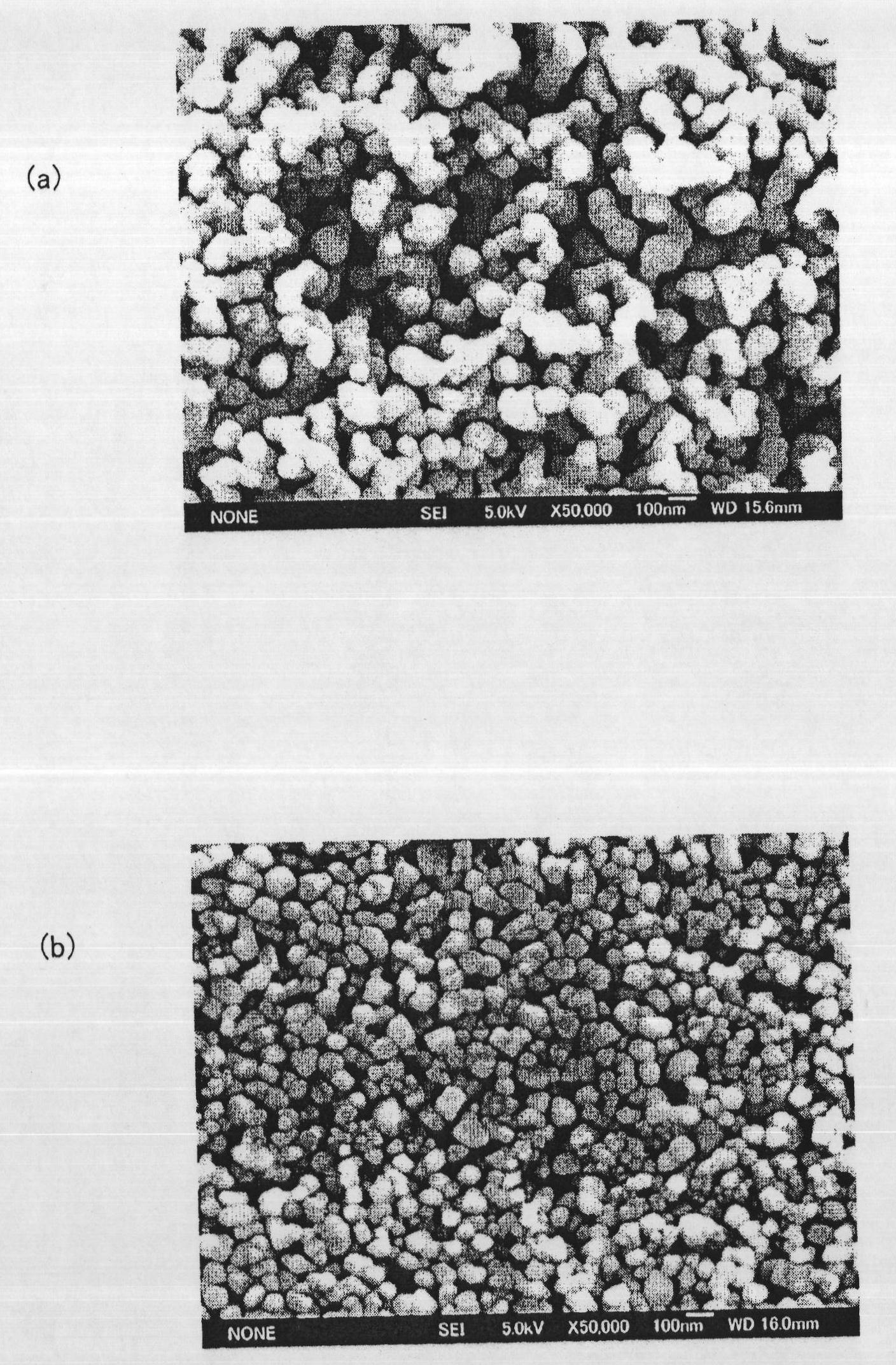

[0043] (A) Production of barium titanate powder

[0044] First, barium titanate (BaTiO 3 )powder. That is, weighing BaCO 3 and TiO 2 The powders are then mixed in a ball mill for 24 hours, and then heat-treated, using a solid-state reaction to obtain BaTiO 3 powder. BaTiO 3 The target particle size of the powder is 6 grades of 10nm, 30nm, 70nm, 100nm, 150nm and 200nm.

[0045] (B) Grading treatment of barium titanate powder

[0046] BaTiO obtained in the process of (A) above with target particle sizes of 10nm, 30nm, 70nm, 100nm, 150nm and 200nm 3 The powders were used as samples 101, 105, 107, 111, 114 and 116 shown in Table 1, respectively.

[0047] In addition, BaTiO obtained in the above-mentioned (A) process and having target particle diameters of 10 nm, 30 nm, 70 nm, 100 nm, 150 nm, and 200 nm were respectively 3 Put the powder into pure water as a dispersion medium in the flask to disperse it, and after standing for a certain period of time, place the BaTiO 3 T...

experiment example 2

[0078] In Experimental Example 2, the (A) preparation of barium titanate powder, (B) classification treatment of barium titanate powder, and (C) preparation of dielectric ceramic raw material powder in Experimental Example 1 were used as they were. The dielectric ceramic raw material powder obtained in each process. Therefore, the sample number in Experimental Example 2 is shared with the sample number in Experimental Example 1.

[0079] In Experimental Example 2, the same procedure as in Experimental Example 1 was performed except that the thickness of the ceramic green sheet was set so as to be 0.3 μm after firing in the production of (D) multilayer ceramic capacitor in Experimental Example 1. (D) The process of producing a multilayer ceramic capacitor is carried out.

[0080] The evaluation results of Experimental Example 2 are shown in Table 2, and Table 2 also shows the evaluation results of the (E-1) barium titanate powder implemented in Experimental Example 1 as it is....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dimensions | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com