Organic-inorganic compound fertilizer and production method thereof

A kind of compound fertilizer and inorganic technology, applied in fertilization equipment, fertilizer mixture, application, etc., can solve the problems of agricultural ecological balance destruction, waste of resources, pollution of the environment, etc., and achieve the effect of high market benefit, high utilization rate and stable state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

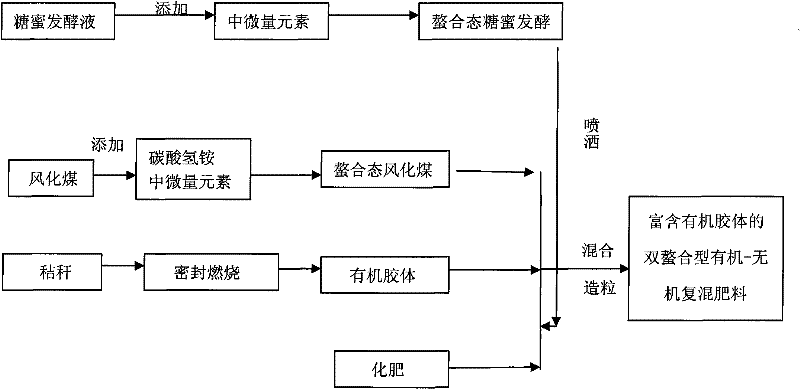

Method used

Image

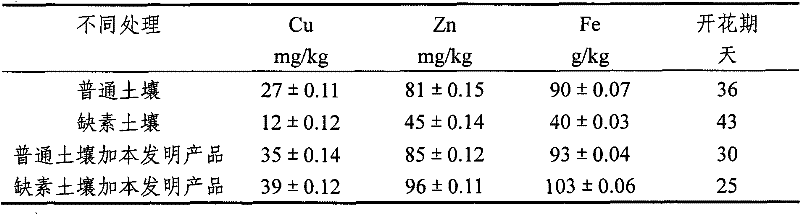

Examples

Embodiment 1

[0028] The preparation of embodiment 1 compound fertilizer

[0029] Put the wheat stalks into a closed furnace at 450°C for carbonization to obtain organic colloids with very small particles in batches, and mix them evenly into chemical fertilizers at a weight ratio of 1:1 (N:P:K=12:9:8 )middle. The molasses fermentation liquid (purchased from Taiwan Vedan Group, with an amino acid content of about 35%) was mixed with the compound amino acid contained in it, boric acid, borax, ammonium molybdate, copper sulfate, ferrous sulfate, manganese sulfate, zinc sulfate, and calcium nitrate in moles. Mix at a ratio of 1:0.8:0.2:1.2:0.7:0.8:0.6:0.4:0.3, adjust the pH value to 7.5 with calcium hydroxide, stir evenly, react at 25°C for 1 hour, and spray the chelating liquid evenly on the mixed organic The surface of the colloidal chemical fertilizer makes the total content of chelated trace elements reach 2% (dry weight), and the primary mixed fertilizer is obtained. Then mix the weather...

Embodiment 2

[0030] The preparation of embodiment 2 compound fertilizer

[0031]Put wheat stalks into a closed furnace at 400°C for carbonization treatment to obtain organic colloids with very small particles in batches, and mix them evenly into chemical fertilizers at a weight ratio of 1:2 (N:P:K=7:8: 7). The molasses fermentation liquid (purchased from Taiwan Vedan Group, with an amino acid content of about 35%) was mixed with the compound amino acid contained in it, boric acid, borax, ammonium molybdate, copper sulfate, ferrous sulfate, manganese sulfate, zinc sulfate, and calcium nitrate in moles. Mix at a ratio of 1:0.8:0.2:1.2:0.7:0.8:0.6:0.4:0.3, adjust the pH value to 7.0 with calcium hydroxide, stir evenly, react at 28°C for 1 hour, and evenly spray the chelating liquid on the mixed organic The surface of the colloidal chemical fertilizer makes the total content of chelated trace elements reach 2% (dry weight), and the primary mixed fertilizer is obtained. Then weathered coal is...

Embodiment 3

[0032] The preparation of embodiment 3 compound fertilizer

[0033] Put the corn stalks into a closed furnace for carbonization at 500°C to obtain organic colloids with very small particles in batches, and mix them evenly into chemical fertilizers (urea) at a weight ratio of 2:1. The molasses fermentation broth (purchased from Taiwan Weidan Group) was mixed with the compound amino acid contained in boric acid, borax, ammonium molybdate, copper sulfate, ferrous sulfate, manganese sulfate, and zinc sulfate in a molar ratio of 1:0.8:0.2:1.2:0.7 : 0.8: 0.6: 0.4, mixed with calcium hydroxide to adjust the pH value to 8.0, stirred evenly, reacted at 23°C for 1 hour, and sprayed the chelating liquid evenly on the surface of the fertilizer mixed with organic colloid to make the total amount of chelated trace elements When the content reaches 3% (dry weight), the primary mixed fertilizer is obtained. Then mix the weathered coal with ammonium bicarbonate, borax, copper sulfate, ferrous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com