High-strength corrosion-resistant nickel-based monocrystal superalloy

A nickel-based single crystal, superalloy technology, used in the field of superalloys, to achieve high oxidation resistance, high high temperature strength, and the effect of eliminating grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention, but they do not limit the present invention.

[0025] The specific preparation method of the alloy is as follows:

[0026] First melt the master alloy of the composition in the carbon-free embodiment in a 25Kg vacuum induction furnace, pour into a master alloy ingot with a diameter of Φ83mm, then add corresponding carbon and corresponding chromium in a 5Kg vacuum induction furnace to prepare the above-mentioned composition. Alloy ingots were ground to remove scale, and cut into suitable blocks for the preparation of single crystal test rods of the composition in the table below.

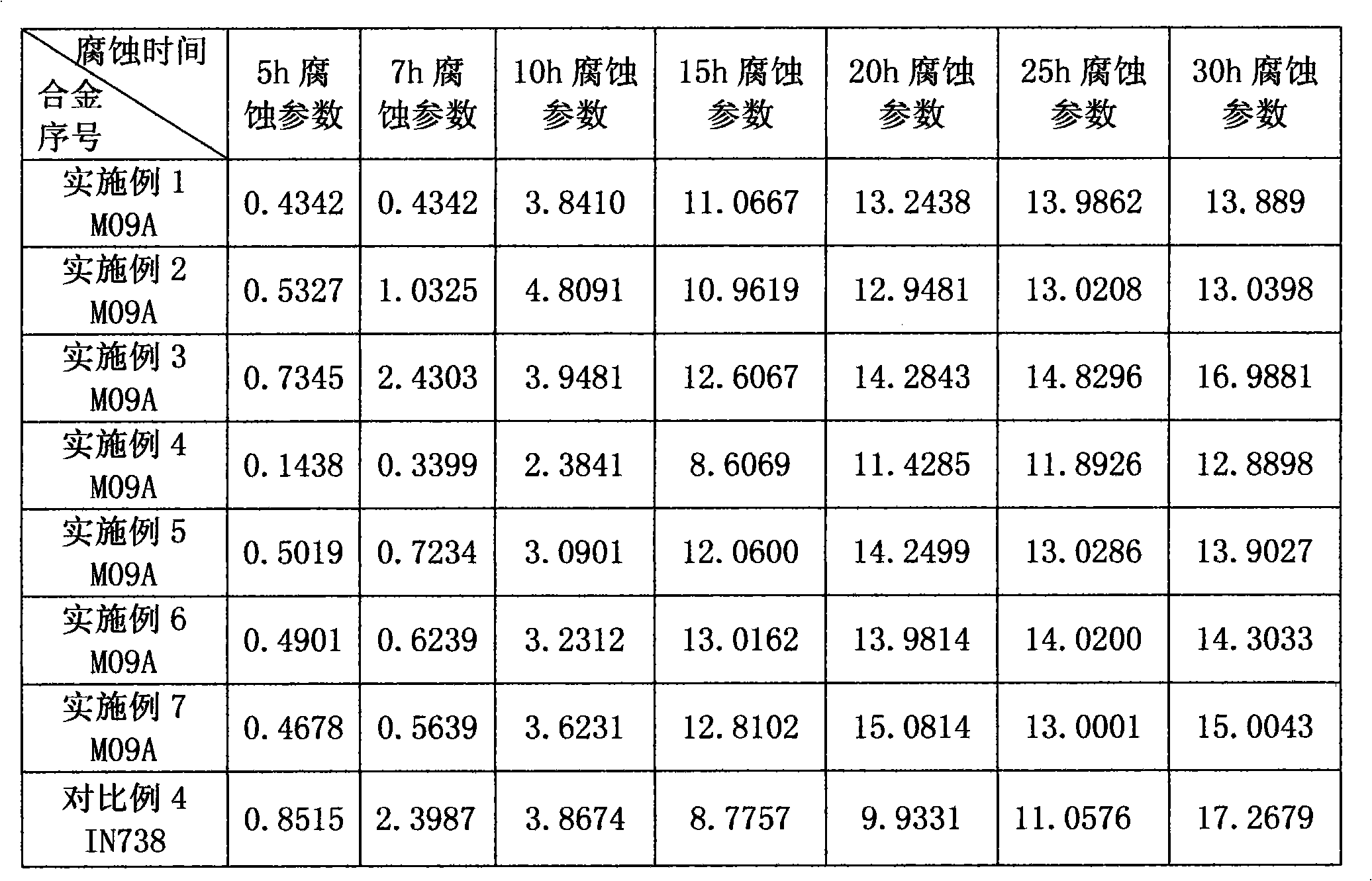

[0027] The alloys in Example 1-Example 7 were prepared according to the above method, and their compositions are shown in Table 1.

[0028] Table 1: The composition (wt %) of embodiment 1-embodiment 7 and comparative example 1-comparative example 4

[0029] serial number

C

Cr

co

Mo

W

Ta

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com