Method for manufacturing intermediate-frequency low-loss MnZn ferrite magnetic core

A ferrite core and manufacturing method technology, applied in the direction of inductance/transformer/magnet manufacturing, inorganic material magnetism, electrical components, etc., can solve the problems of difficult uniform dispersion of nano-additives, easy agglomeration of nano-materials, high sintering temperature, etc., to achieve High saturation magnetic flux density, good powder activity, and low pre-burning temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

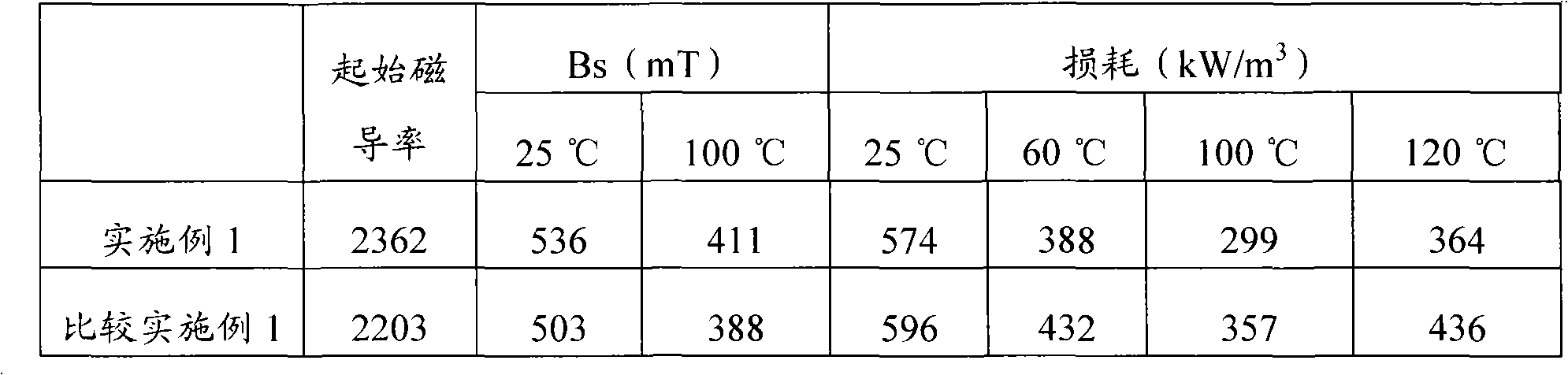

Embodiment 1

[0032] Weigh the main component: 67wt% Fe with a purity of 99.3% or more 2 o 3 , 24wt% Mn 3 o 4 (Mn content is 71.1%), the purity of 9wt% is ZnO more than 99.7%, takes by weighing low-temperature flux simultaneously: CuO based on the CuO of 0.2wt% of main component gross weight; Add 80wt% water of the total weight of the powder to the material, stir and grind to mix evenly; after spray drying, pre-calcine at 800°C for 2 hours; based on the total weight of the pre-calcined powder, add additives: 0.04wt% CaCO 3 , 0.003wt% SiO 2 , 0.02wt% Nb 2 o 5 , 0.01wt% ZrO 2 And then add low temperature flux: 0.06wt% TiO 2, then add 60wt% of deionized water, 1wt% of dispersant, and 1wt% of defoamer for secondary grinding until the average particle size is 1.0±0.2μm; after drying, based on the total amount of ground powder Weight, in this powder, add the aqueous solution granulation of the polyvinyl alcohol of 8wt% (above each material can be purchased from the market); Green sample...

Embodiment 2

[0040] Weigh the main component: 70wt% Fe with a purity of 99.3% or more 2 o 3 , 23wt% Mn 3 o 4 (Mn content is 71.1%), the purity of 7wt% is 99.7% ZnO, weighs low-temperature flux simultaneously: based on the SnO of 0.25wt% of main component gross weight 2 and 0.25wt% TiO 2 ; In the sand mill, add 90wt% water of the total weight of the powder to the powder weighed above, stir and grind and mix evenly; after spray drying, pre-calcine at 780 ° C for 3 hours; based on the pre-calcined The total weight of the powder, adding additives: 0.05wt% CaCO 3 , 0.004wt% SiO 2 , 0.03wt% Nb 2 o 5 , 0.02wt% ZrO 2 And then add low temperature flux: 0.09wt% SnO 2 , and then add 70wt% deionized water, 1wt% dispersant, and 1wt% defoamer for secondary grinding, until the average particle size is 1.0±0.2μm; after drying, based on the total amount of ground powder Weight, in this powder, add the aqueous solution granulation of the polyvinyl alcohol of 8wt% (above each material can be purcha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com