MnZn ferrite material with low temperature coefficient and low loss at high frequency and preparation method thereof

A low temperature coefficient, ferrite material technology, applied in the direction of magnetic materials, inorganic material magnetism, magnetic objects, etc., can solve the problems of increasing the cost and high price of MnZn ferrite materials, achieve excellent electromagnetic properties, and help reduce The effect of falling, low temperature coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

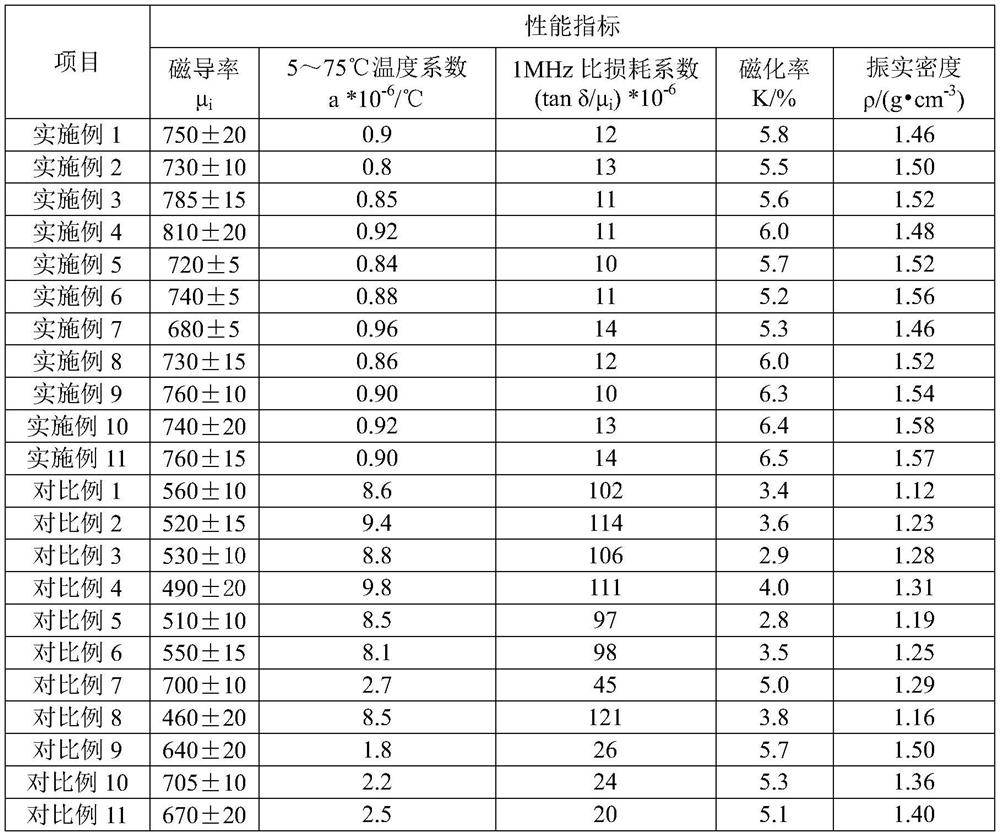

Examples

Embodiment 1

[0030] A MnZn ferrite material with low temperature coefficient and low loss at high frequency is made of main component, first auxiliary component and second auxiliary component, and its preparation process is as follows:

[0031] (1) Ingredients: mix the main component, the first auxiliary component and the second auxiliary component to obtain a mixed material, wherein,

[0032] The main components are: Fe 2 o 3 : 5.5mol, ZnO: 0.6mol, MnO: 3.9mol;

[0033] Based on the main component, the first auxiliary component is: CaO: 1000ppm, Nb 2 o 5 : 0.04ppm, ZrO 2 : 0.04ppm, V 2 o 5 : 400ppm, Bi 2 o 3 : 800ppm;

[0034] Based on the main component: the second auxiliary component is: MoO 3 : 200ppm, Co 2 o 3 : 1000ppm and TiO 2 : 1000ppm;

[0035] (2) One-time sanding: sand the mixed material in a sand mill, the mass ratio of sanding material, balls and water is 1:1:0.6, the sanding time is 3 hours, and the average particle size after sanding is 1.0 μm;

[0036] (3) Low...

Embodiment 2

[0041] A kind of MnZn ferrite material with low temperature coefficient and low loss when high frequency, compared with embodiment 1, the difference is that in the batching of step (1):

[0042] The main components are: Fe 2 o 3 : 5.4mol, ZnO: 0.8mol, MnO 3.8mol;

[0043] Based on the main components, the first auxiliary components are: CaO: 300ppm, Nb 2 o 5 : 0.01ppm, ZrO 2 : 0.01ppm, V 2 o 5 : 300ppm, Bi 2 o 3 : 1000ppm;

[0044] Based on the main component: the second auxiliary component is: MoO 3 : 400ppm, Co 2 o 3 : 300ppm and TiO 2 : 100ppm.

Embodiment 3

[0046] A kind of MnZn ferrite material with low temperature coefficient and low loss when high frequency, compared with embodiment 1, the difference is that in the batching of step (1):

[0047] The main components are: Fe 2 o 3 : 5.7mol, ZnO: 0.5mol, MnO: 3.8mol;

[0048] Based on the main components, the first auxiliary components are: CaO: 1200ppm, Nb 2 o 5 : 0.04ppm, ZrO 2 : 0.06ppm, V 2 o 5 : 500ppm, Bi 2 o 3 : 300ppm;

[0049] Based on the main component: the second auxiliary component is: MoO 3 : 800ppm, Co 2 o 3 : 2000ppm and TiO 2 : 3000ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com