Dual-niobium-source alkali metal niobate micro-nano wire material and preparation method thereof

An alkali metal niobate and micro-nano technology, which is applied in the field of micro-nano materials, can solve problems such as high energy consumption, equipment requirements, production safety issues, affecting powder activity, and increased production costs, so as to shorten the holding time, Improve crystallinity and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of a double niobium source alkali metal niobate micro-nano wire material:

[0031] Step (1) All raw materials K 2 CO 3 、Na 2 CO 3 , Nb 2 o 5 、C 10 h 5 NbO 20 、BaCO 3 、 Bi 2 o 3 Before weighing the ingredients, they are all placed in an oven for drying, and the drying temperature is 120°C;

[0032] Step (2) according to the chemical formula (1- y )K z Na 1-z Nb (c)xNb(N)1-x o 3 - y BaBiO 3 Component mass ratio Weighing raw materials, where Nb (C) means from C 10 h 5 NbO 20 Nb element; Nb (N) means from Nb 2 o 5Nb element of ; x = 0.01, y = 0.05, z = 0.54. Put it into a ball mill bottle, and use purified water and zirconia balls as the medium for ball milling for 24 hours;

[0033] Step (3) The powder after ball milling is taken out, dried, and pre-fired. The pre-fired temperature is 200°C for 3 hours, then raised to 500°C for 3 hours, and the heating rate is 1min / °C;

[0034] Step (4) Then put the pre-fired powder into the ...

Embodiment 2

[0039] A preparation method of a double niobium source alkali metal niobate micro-nano wire material:

[0040] The steps that are not specifically described are the same as the preparation method of Example 1, except that in step (6), the heat preservation treatment is carried out for 18 hours.

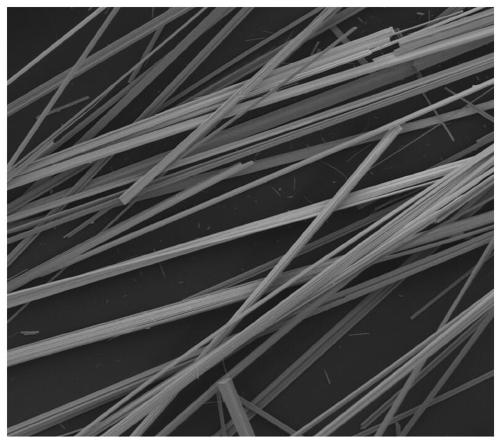

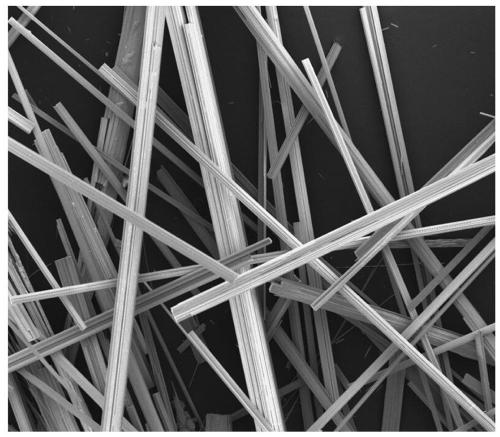

[0041] Through SEM detection, the obtained double niobium source alkali metal niobate micro-nano wire material.

Embodiment 3

[0043] A preparation method of a double niobium source alkali metal niobate micro-nano wire material:

[0044] The steps that are not specifically described are the same as the preparation method of Example 1, except that in step (6), the heat preservation treatment is carried out for 24 hours.

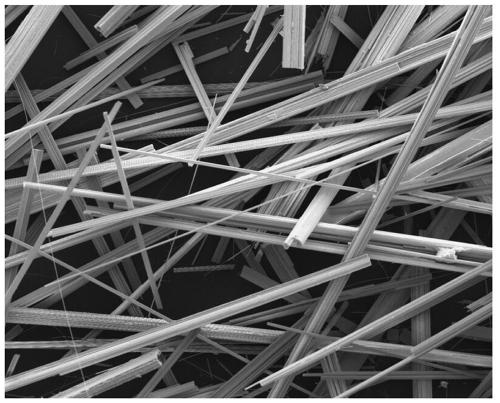

[0045] After SEM detection, the obtained double niobium source alkali metal niobate micro-nano wire material is as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com