Two-phase wet-type anaerobic digestion treatment method of food waste

A technology of food waste and anaerobic digestion, which is applied in the field of food waste treatment and two-phase wet anaerobic digestion treatment of food waste, which can solve the problems of low VFA yield, high processing cost, and large power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

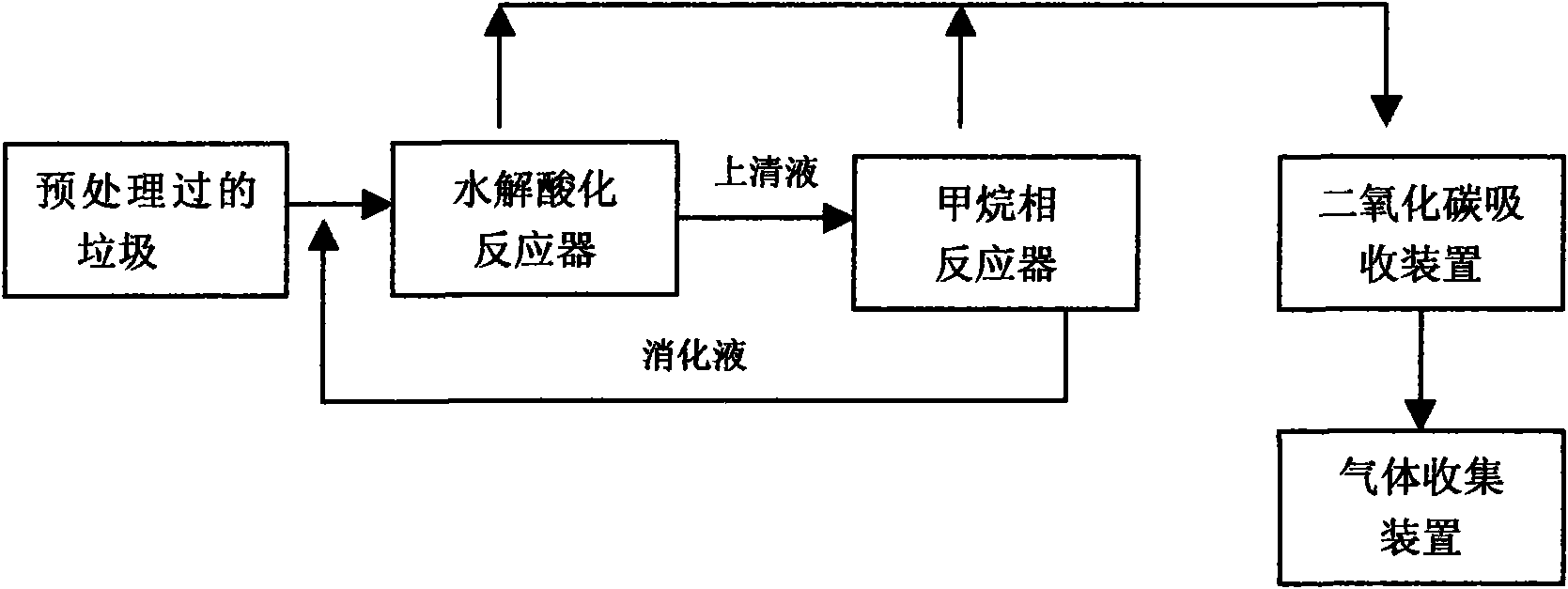

Method used

Image

Examples

Embodiment 1

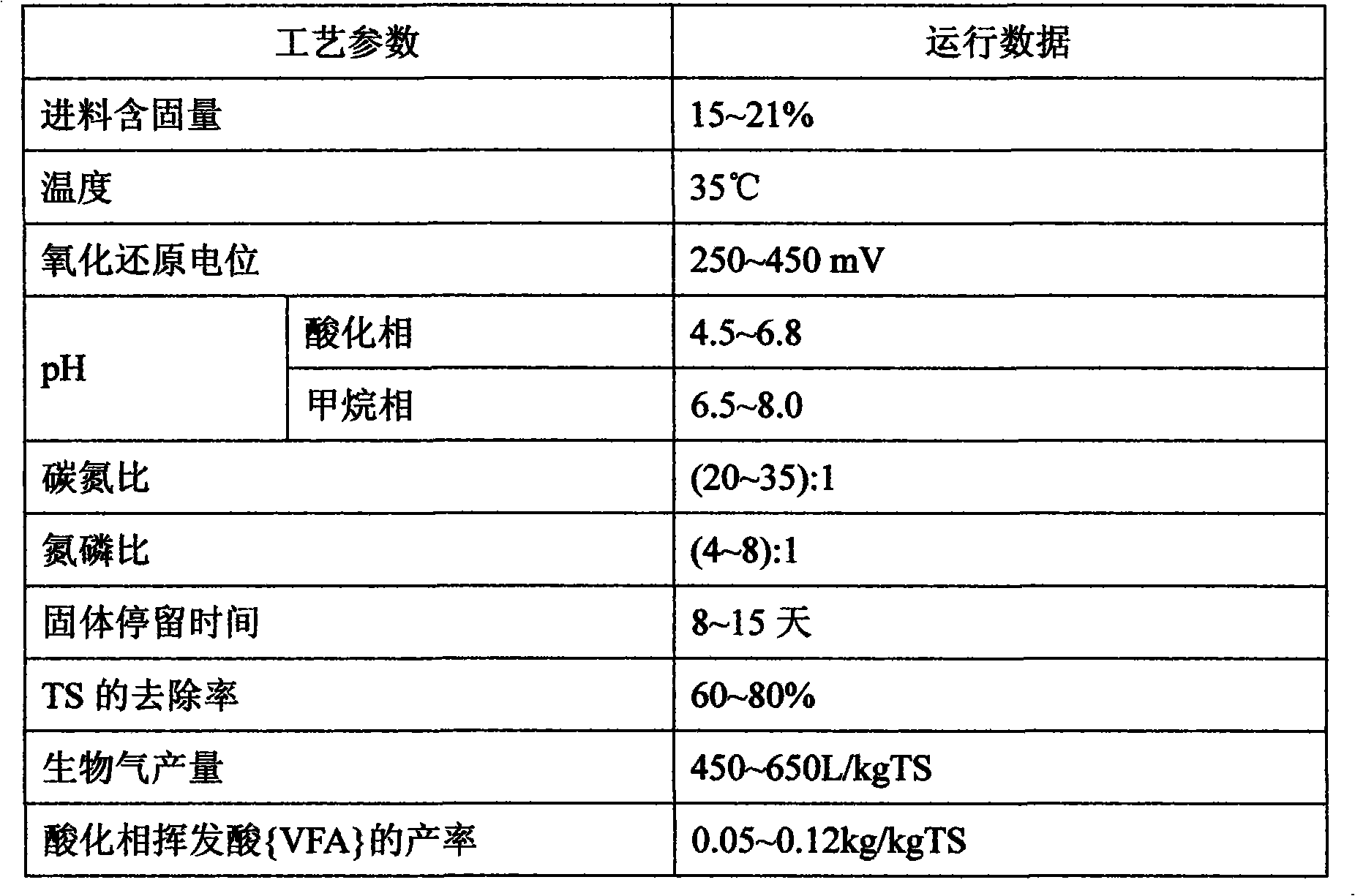

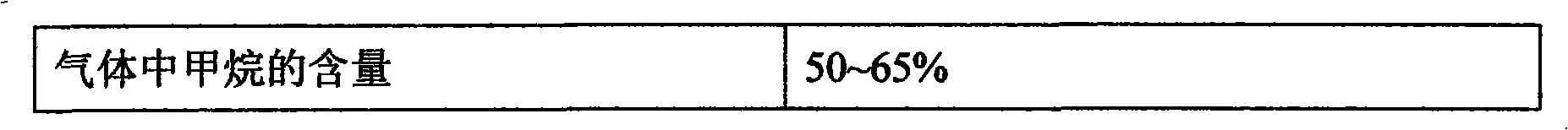

[0022] Take the garbage in the canteen of the North District of Shanghai Jiao Tong University as an example. Generally speaking, food waste mainly contains three types of substances: carbohydrates, fats and proteins. The garbage used in this embodiment contains more carbohydrates, and the water content is 55% to 65%. After adding water and pulverizing, the solid content is 30% to 50%. Dilution is performed to adjust the feed solid content to 15% to 21%. The carbon dioxide absorption device is equipped with sodium hydroxide absorption liquid, and the concentration of the absorption liquid is determined according to the carbon dioxide content in the gas obtained from the test.

[0023] What adopted in the present embodiment is medium temperature (35 DEG C), adopt the method of the present invention, not only can reduce operating cost, and the stability of process operation and treatment effect are all better than existing two-phase anaerobic digestion treatment method, TS (solid...

Embodiment 2

[0028] Take the garbage of Shanghai Wisteria Hotel as an example. There is a certain difference between hotel garbage and student canteen garbage, which contains more oily substances, accounting for 50-70% of the total solids. use as figure 1 In the process flow shown, the garbage is crushed first, and then diluted before entering the acidification reactor to make its solid content 5-10%. Since oil is more difficult to degrade than carbohydrates, a longer solid retention time is adopted. time.

[0029]

Embodiment 3

[0031] Take the kitchen waste of the Lingering Garden Hotel in Shanghai Jiaotong University as an example. After sampling and testing, it was found that the protein content in the food waste of Lingering Garden Hotel was relatively high, accounting for 45-60% of the total solid content. figure 1 In the process shown, the temperature of the acidification phase in this embodiment is 55°C, the temperature of the methane phase is 35°C, and the temperature, pH and oxidation-reduction potential (ORP) in the reactor are tracked and detected, and the operating results are as follows:

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com