Stainless steel and cast iron oxy-acetylene cutter

An oxyacetylene cutting and stainless steel technology, applied in the field of cast iron oxyacetylene cutting gun and stainless steel, can solve the problems of poor powder discharge and low use efficiency, and achieve smooth discharge, enlarged use range, and safe and reliable work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

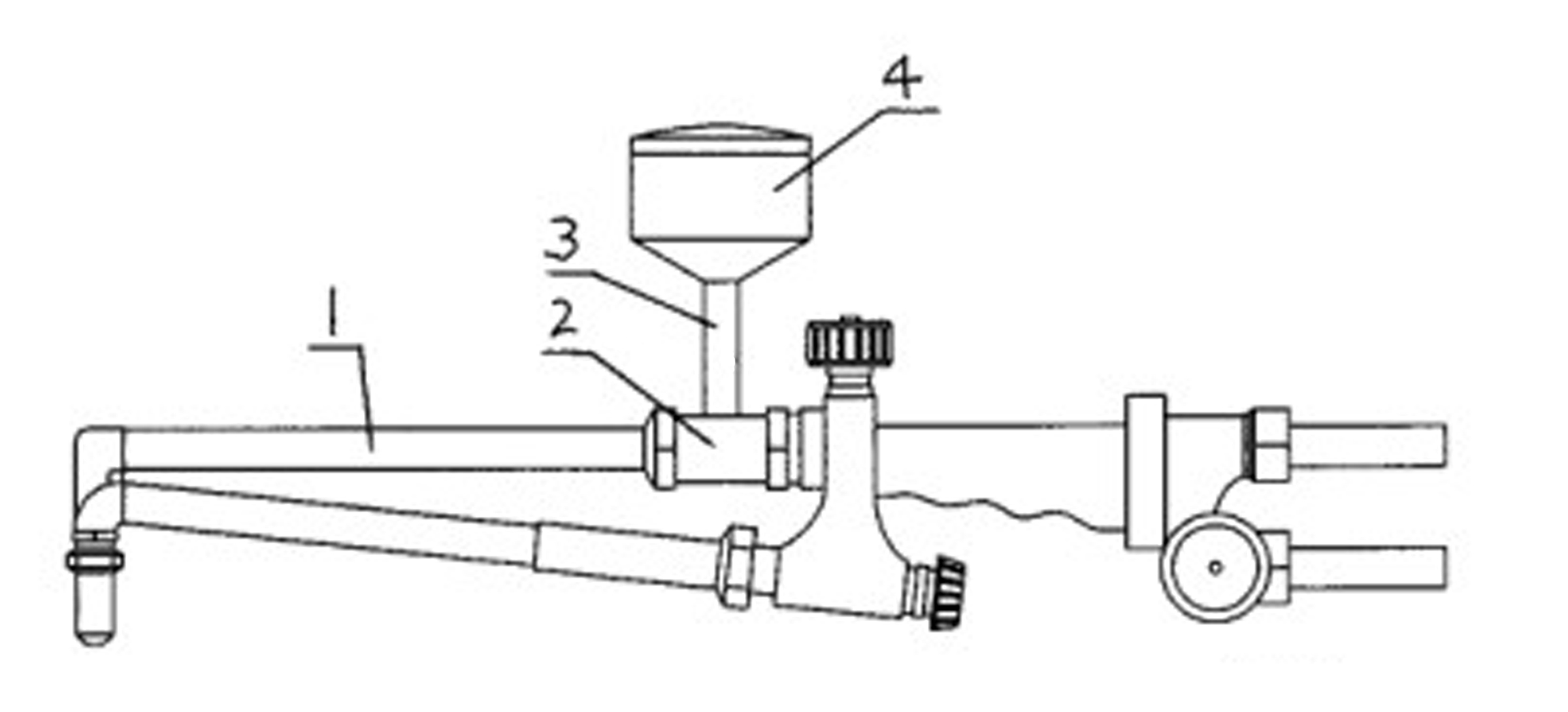

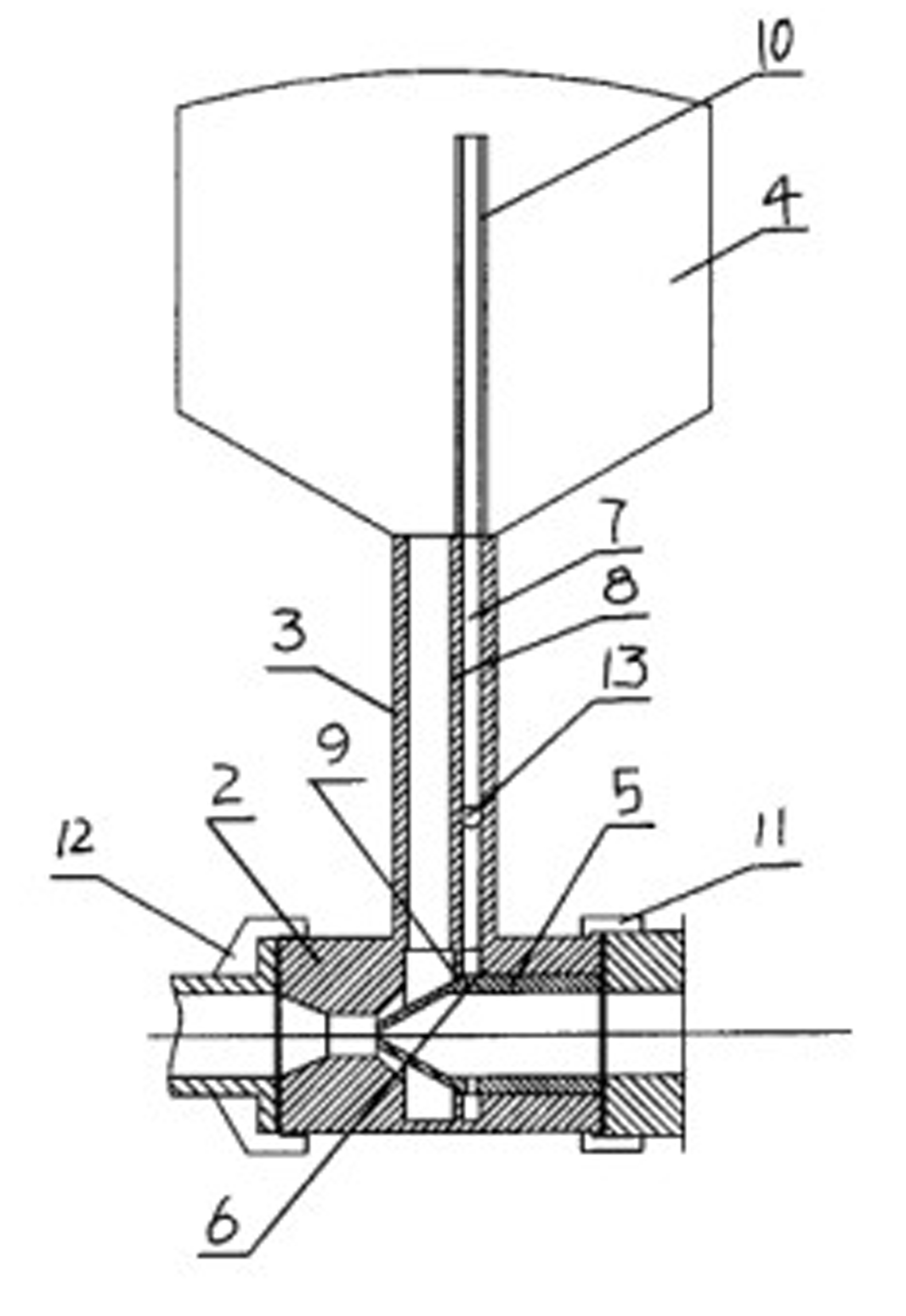

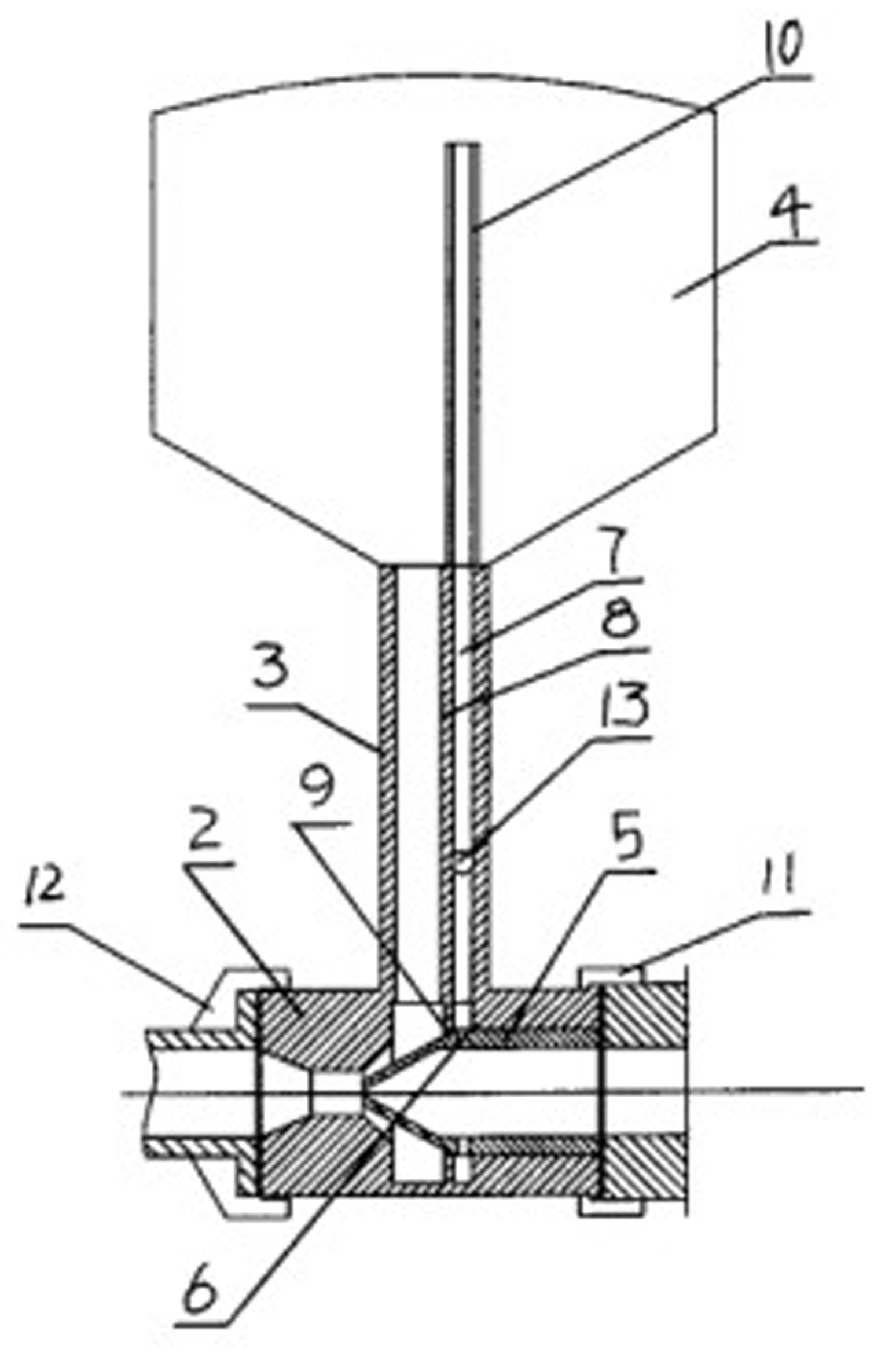

[0012] Stainless steel, cast iron oxyacetylene cutting torch, including pure oxygen injection pipe 1, on which a powder blowing device is installed, the powder blowing device includes a pipe body 2, a bypass pipe 3 is arranged on the pipe body 2, the bypass pipe A powder tank 4 is connected and fixed on the tube 3, a suction pipe 5 is arranged in the pipe body 2, and a hole 6 is opened on the suction pipe 5, and an oxygen blowing channel 7 is arranged in the bypass pipe 3 on the pipe body, and an oxygen blowing channel 7 is arranged in the suction pipe 5. The cavity communicates with the powder tank 4 through the hole 6 on the injection pipe and the oxygen blowing channel 7 in the bypass pipe. During specific implementation, the oxygen blowing passage 7 is formed on one side of the partition by setting the partition 8 in the bypass pipe 3, and the sealing connection between the partition 8 and the injection suction pipe 5, between the partition 8 and the injection suction pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com