Solid hydrogen fuel, manufacturing method and use method thereof

A manufacturing method and solid-state hydrogen technology, which can be applied in the production of hydrogen and other directions, and can solve the problems of low hydrogen release rate, hydrogen release rate decrease, loss of hydrogen storage capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above-mentioned content of the present invention more comprehensible, a preferred embodiment is specifically cited below and described in detail with accompanying drawings.

[0026]

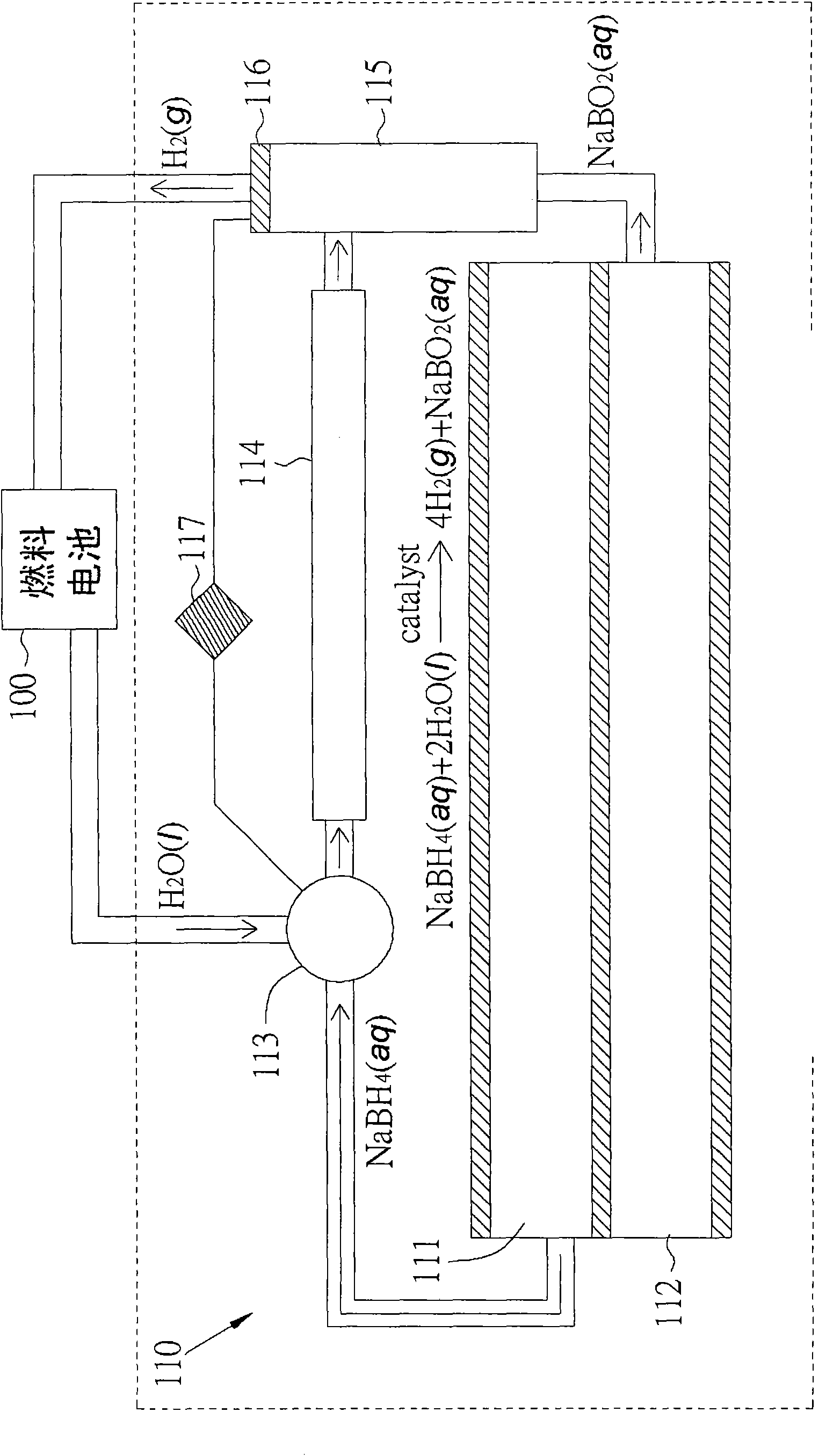

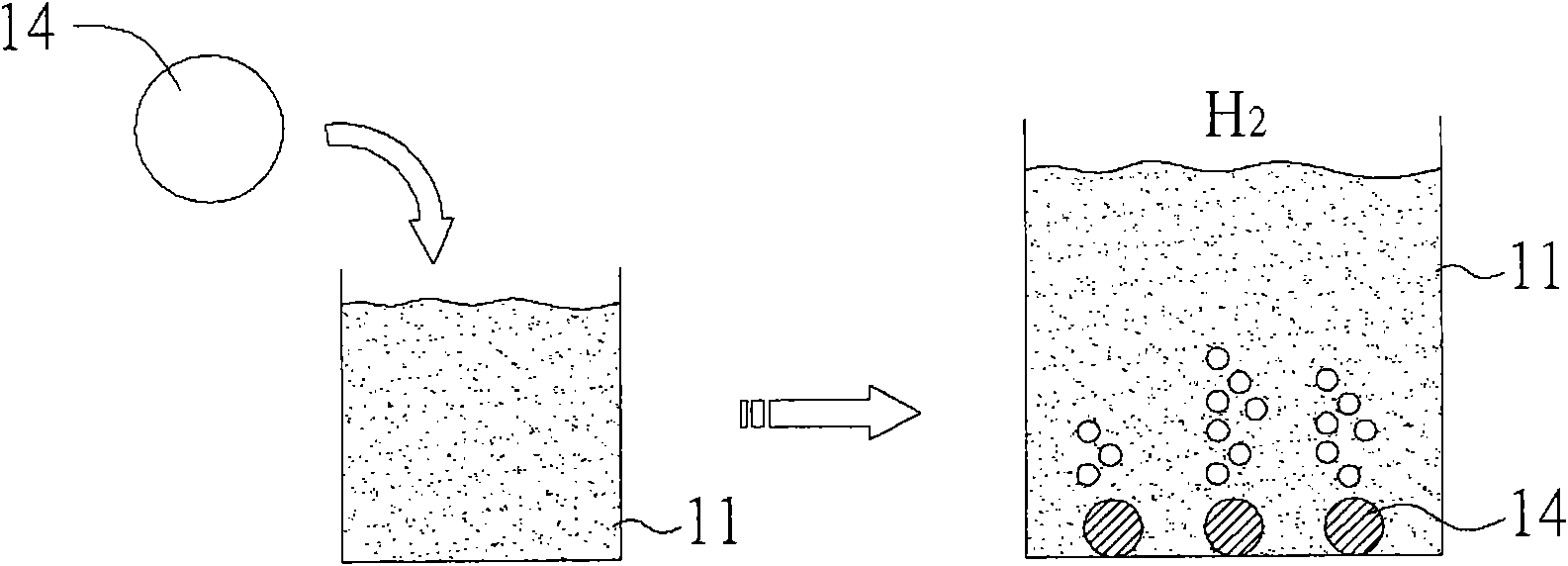

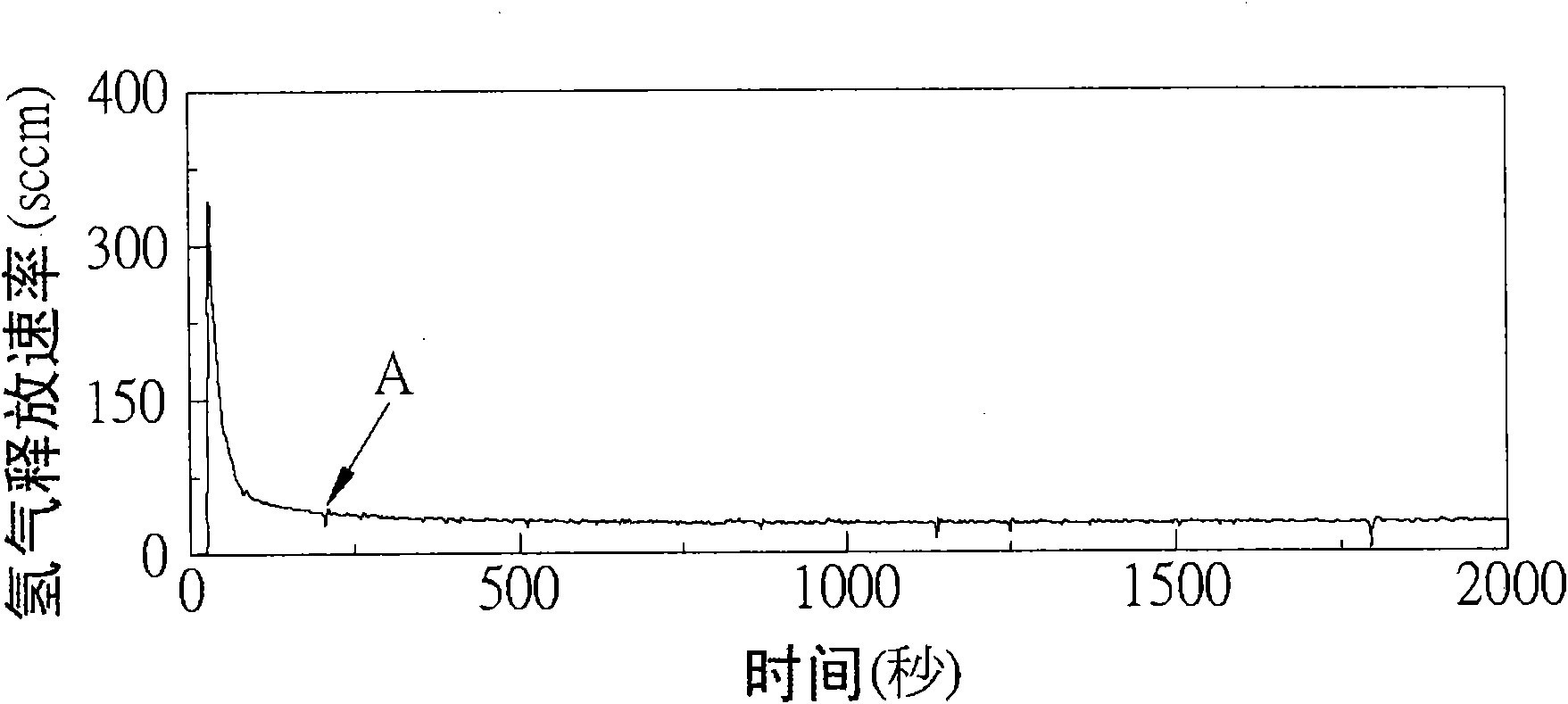

[0027] In an embodiment of the present invention, a solid hydrogen fuel for hydrogen production in a fuel cell is proposed, which is formed by uniformly mixing solid hydride powder and catalyst powder. The solid hydrogen fuel can be mixed with water to generate hydrogen as shown in the above chemical reaction formula (1), and the hydrogen desorption rate is fast, which can be applied to high-power fuel cells. Moreover, compared with the traditional hydride aqueous solution, the hydrogen generation amount of the solid hydride is higher than that of the traditional liquid hydride (the theoretical value of the traditional liquid hydride is up to 4.6wt%). In addition, after the powder is compacted to form a block, it is easy to carry and the form can be changed, and it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com