Water electrolysis hydrogen production system suitable for fluctuating power supply and control strategy thereof

A hydrogen production system, a fluctuating technology, applied in electrical energy storage systems, electrolysis processes, electrolysis components, etc., can solve problems such as safety hazards, access, and cost reduction of hydrogen production from electrolysis water, and achieve reduced fluctuation and high hydrogen production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

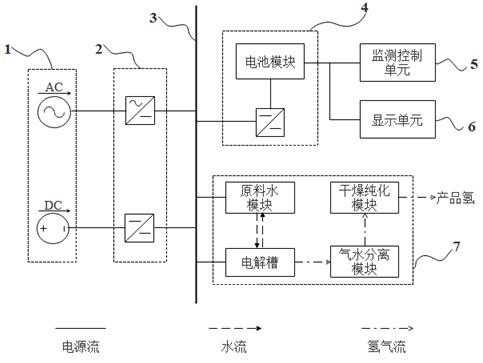

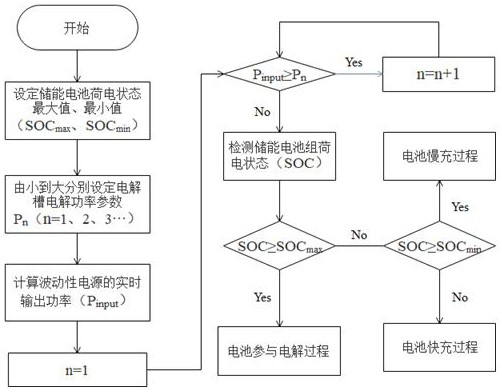

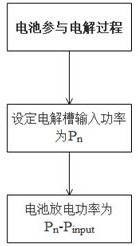

[0040] Such as figure 1 As shown, the present invention provides a hydrogen production system suitable for electrolysis of water with a fluctuating power supply, including a fluctuating power supply 1, a rectification / inverting unit 2, a common DC bus 3, an energy storage battery unit 4, a monitoring control unit 5, and a display Unit 6, hydrogen production unit 7 by electrolysis of water. Among them, the AC or DC power generated by the fluctuating power supply 1 is converted into DC power by the rectifier / inverter unit 2 and then transmitted to the input terminal of the common DC bus 3; the energy storage battery unit 4 is connected to both the input terminal of the common DC bus 3 and the output terminal of the common DC bus 3 Connected; the energy storage battery unit 4 is also connected to the monitoring control unit 5 and the display unit 6; the signal output end of the fluctuating power supply 1 and the electrolytic water hydrogen production unit 7 is connected to the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com