Rutile TiO2 nanowire array synthesized by soft chemistry and hydrothermal technology and preparation method thereof

A nanowire array, rutile phase technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of complex preparation process, and achieve the effect of high photocatalytic activity, good photocatalytic activity, and no need for high temperature heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

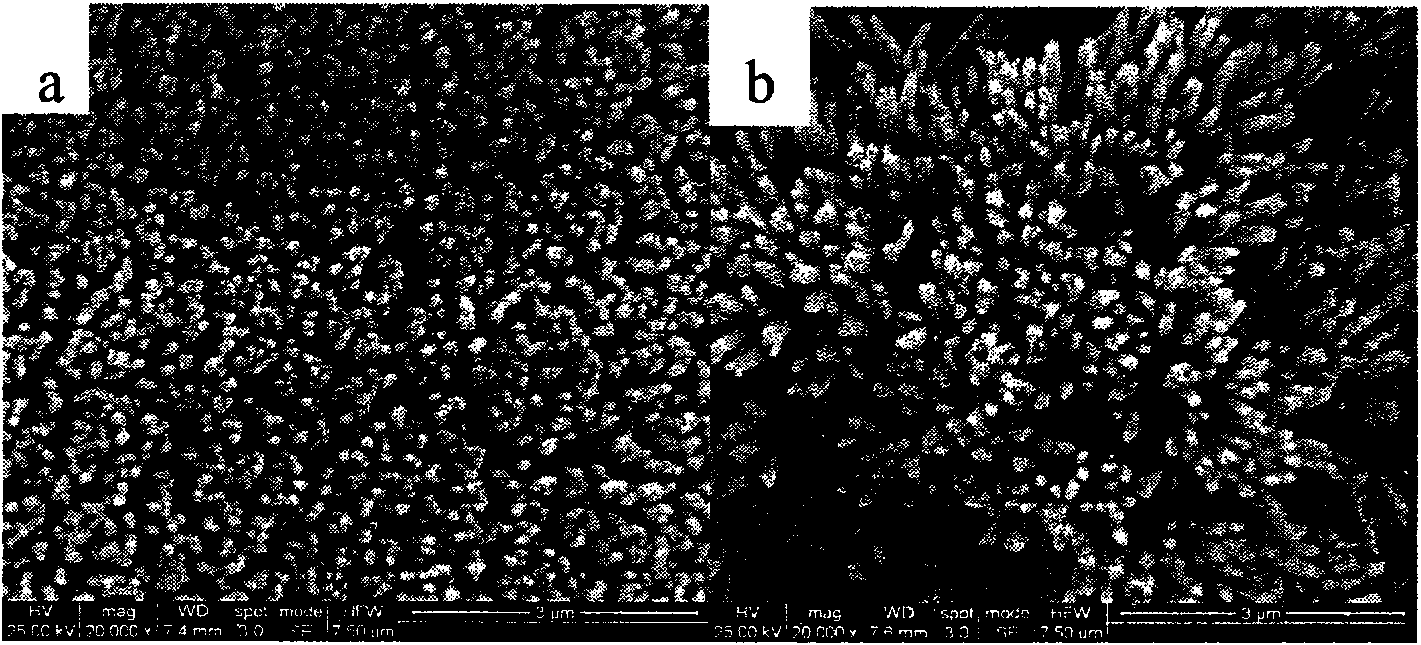

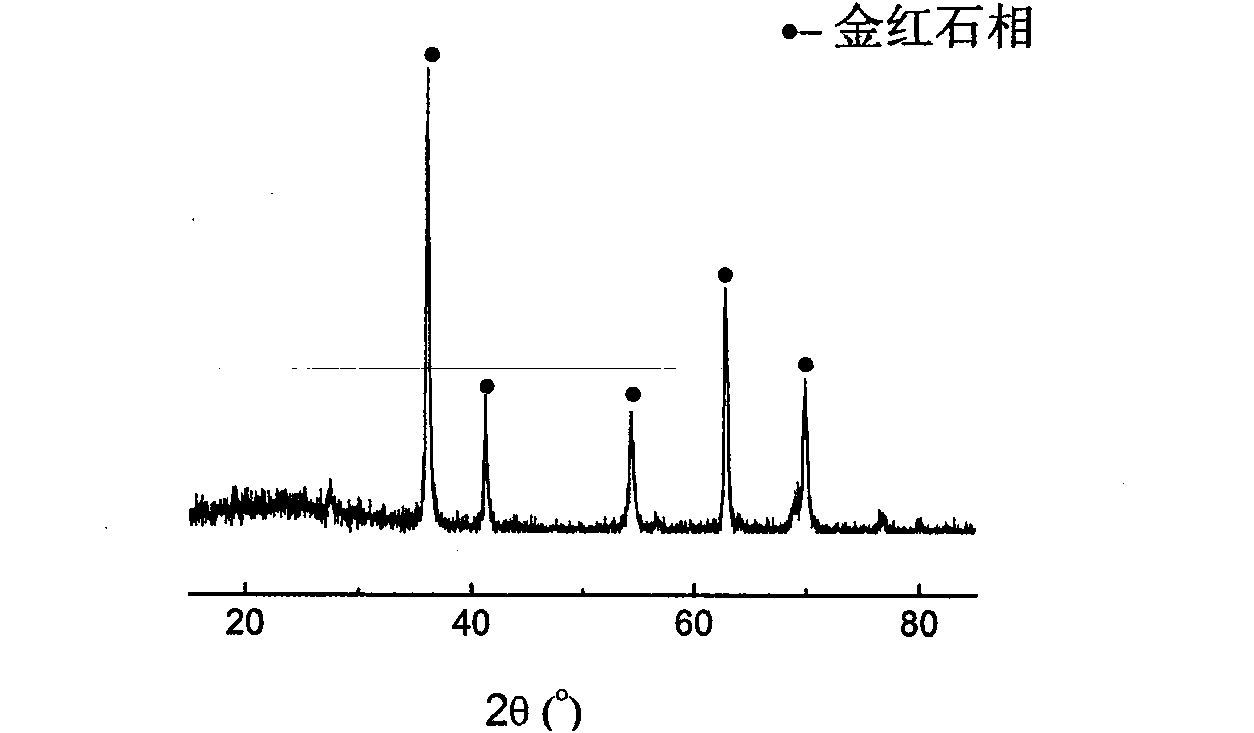

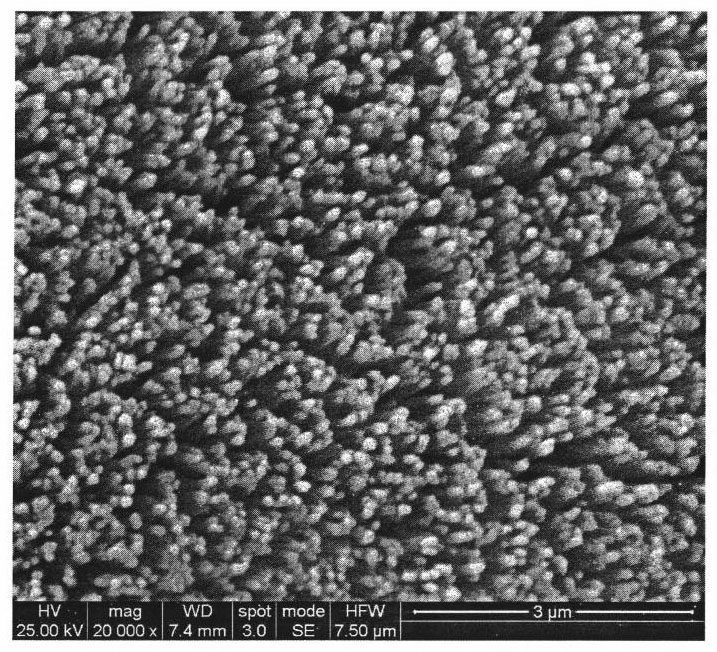

[0019] Put the glass slide cleaned with ethanol solution into an ultrasonic cleaner for a few minutes, and then clean it with deionized water. It was placed in a sealed reaction vessel lined with Teflon for later use. Using toluene as a solvent, prepare a tetrabutyl titanate solution with a concentration of 1mol / L and a titanium tetrachloride solution with a concentration of 1mon / L, respectively. Drainage with a glass rod, slowly add a certain amount of concentrated hydrochloric acid, toluene, tetrabutyl titanate solution and titanium tetrachloride solution into the reaction kettle, so that the volume ratio is 1:10:1:1. Then the reaction kettle was placed in an oven with a temperature of 180° C., and it was taken out after 22 hours. After it cools down, take out the slide at the bottom, and you will get TiO on the slide 2 nanowire array.

Embodiment 2

[0021] Put the glass slide cleaned with ethanol solution into an ultrasonic cleaner for a few minutes, and then clean it with deionized water. It was placed in a sealed reaction vessel lined with Teflon for later use. Using toluene as solvent, prepare a tetrabutyl titanate solution with a concentration of 1mon / L and a titanium tetrachloride solution with a concentration of 1mon / L, respectively. Drainage with a glass rod, slowly add a certain amount of concentrated hydrochloric acid, toluene, tetrabutyl titanate solution and titanium tetrachloride solution into the reaction kettle, so that the volume ratio is 1:10:1:1. The reaction kettle was then placed in an oven at a temperature of 180° C., and it was taken out after 14 hours. After it cools down, take out the slide at the bottom, and you will get TiO on the slide 2 nanowire array.

Embodiment 3

[0023] Put the glass slide cleaned with ethanol solution into an ultrasonic cleaner for a few minutes, and then clean it with deionized water. It was placed in a sealed reaction vessel lined with Teflon for later use. Using toluene as solvent, prepare a tetrabutyl titanate solution with a concentration of 1mon / L and a titanium tetrachloride solution with a concentration of 1mon / L, respectively. Drainage with a glass rod, slowly add a certain amount of concentrated hydrochloric acid, toluene, tetrabutyl titanate solution and titanium tetrachloride solution into the reaction kettle, so that the volume ratio is 1:10:1:1. The reaction kettle was then placed in an oven at a temperature of 180° C., and it was taken out after 6 hours. After it cools down, take out the slide at the bottom, and you will get TiO on the slide 2 nanowire array.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com