Culture water secondary filter system

A technology for secondary filtration and aquaculture water, applied in the field of aquaculture water treatment, can solve problems such as inability to achieve complete denitrification, failure to meet the best conditions for denitrification by nitrifying bacteria, pH changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

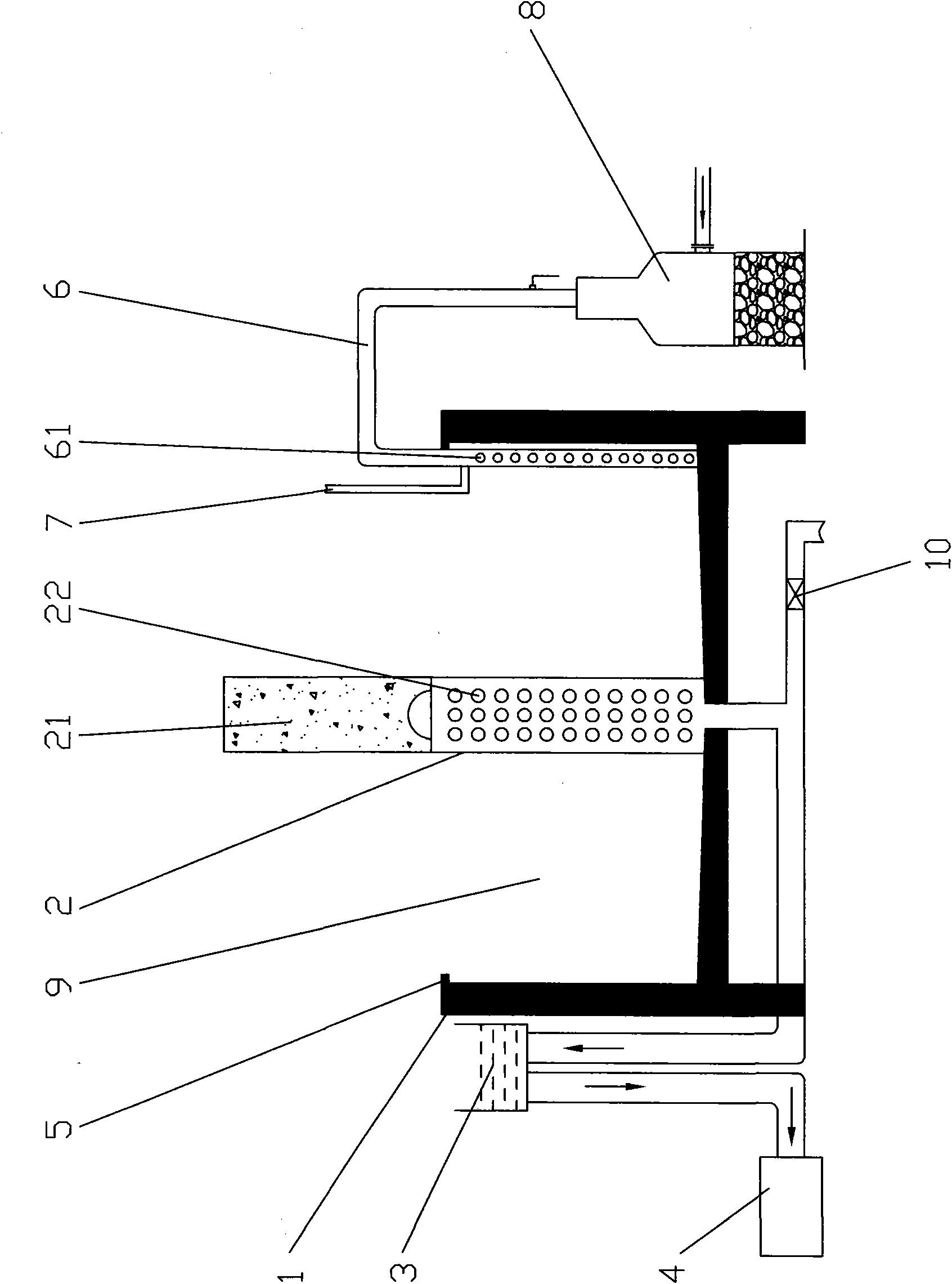

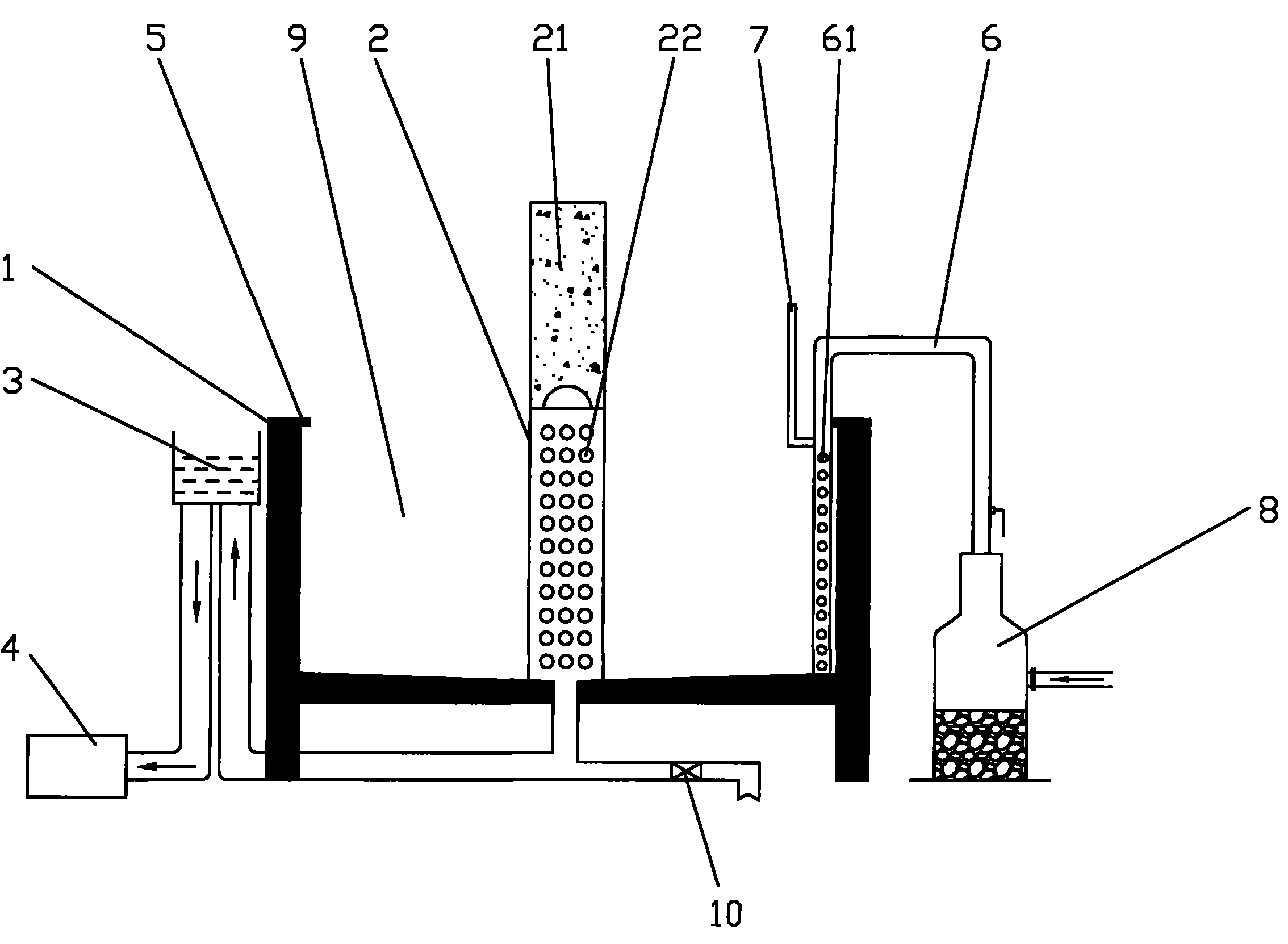

[0021] see figure 1 , a secondary filtration system for aquaculture water, a return pipe 2 that runs through the bottom of the pond body 9 is provided in the center of the aquaculture pond body 9, a return water hole 22 is provided at the bottom of the return pipe 2, and a return pipe 2 is installed inside the upper part of the return pipe 2 Spiral biological ball 21, the culture water pumped by the submersible pump at the bottom of the pool enters from the return hole 22 at the bottom of the return pipe 2, and the water is discharged after being treated by the spiral biological ball 21 installed in the upper part of the return pipe 2, reducing ammonia nitrogen, Nitrite nitrogen and suspended matter; the return pipe 2 communicates with the water level controller 3 outside the pool through the return hole 22 to form a self-flowing return water system. When the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com