Environment-friendly sludge modifier

A modifier and environment-friendly technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of secondary pollution, low comprehensive utilization efficiency of metallurgical slag, high treatment cost, etc., achieve low production cost, improve treatment Good effect with disposal efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Preparation of environment-friendly sludge modifier:

[0015] (1) Weigh blast furnace slag powder, gypsum and FDN water reducer from iron and steel enterprises, and their weight percentages are 93%, 5%, and 2% respectively, and grind them finely so that the specific surface area is not less than 450m 2 / kg, and then put it in an oven and dry at 85°C for 2 hours to obtain slag composite powder for future use; (2) take steel slag from iron and steel enterprises, crush and magnetically separate it, and control its particle size to no more than 5mm to obtain steel slag for future use. (3) the slag composite powder that step (1) obtains is mixed with the steel slag that step (2) obtains, wherein the slag composite powder accounts for 15% by weight of the slag composite powder and steel slag weight sum, and steel slag accounts for slag composite powder and steel slag The weight percentage of the weight sum is 85%, and the weight percentage is dried to obtain an environment-fr...

Embodiment 2

[0019] Preparation of environment-friendly sludge modifier:

[0020] (1) Take iron and steel enterprise blast furnace slag powder, gypsum, calcium lignosulfonate water reducer and FDN water reducer, and its percentage by weight is respectively 96%, 3%, 0.3%, 0.7%, grind finely, make it compare Surface area not less than 450m 2 / kg, and then put it in an oven and dry at 85°C for 2 hours to obtain slag composite powder for future use; (2) take steel slag from iron and steel enterprises, crush and magnetically separate it, and control its particle size to no more than 5mm to obtain steel slag for future use. (3) get the slag composite powder that step (1) obtains and the steel slag that step (2) obtains and mix, wherein the slag composite powder accounts for slag composite powder and steel slag weight and percentage by weight is 50%, and steel slag accounts for slag composite powder and steel slag The weight percentage of the weight sum is 50% and dried to obtain an environment-...

Embodiment 3~5

[0024] Preparation of environment-friendly sludge modifier:

[0025] The raw materials were selected according to the corresponding raw material proportions of each embodiment in Table 2 and Table 3, and the method of Example 1 was used to prepare the environment-friendly sludge improver.

[0026] Modified sludge:

[0027] Weigh 5 Kg of the environment-friendly sludge modifiers prepared in Examples 3 to 5, respectively, and modify the sludge by the method of Example 1 to obtain the modified sludge.

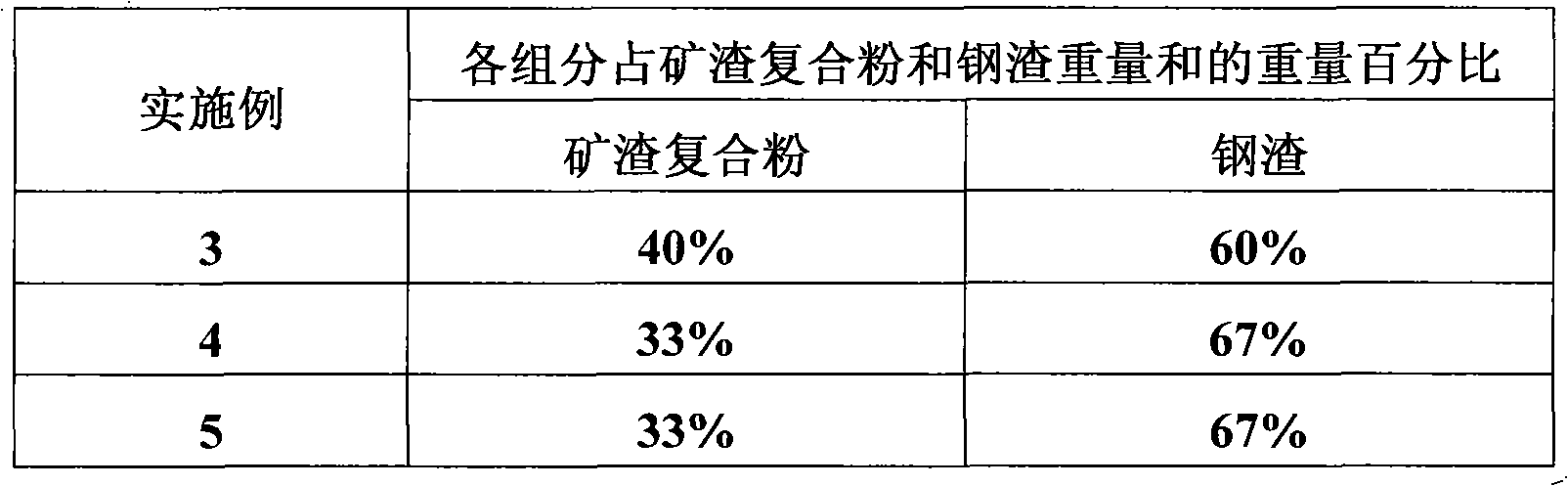

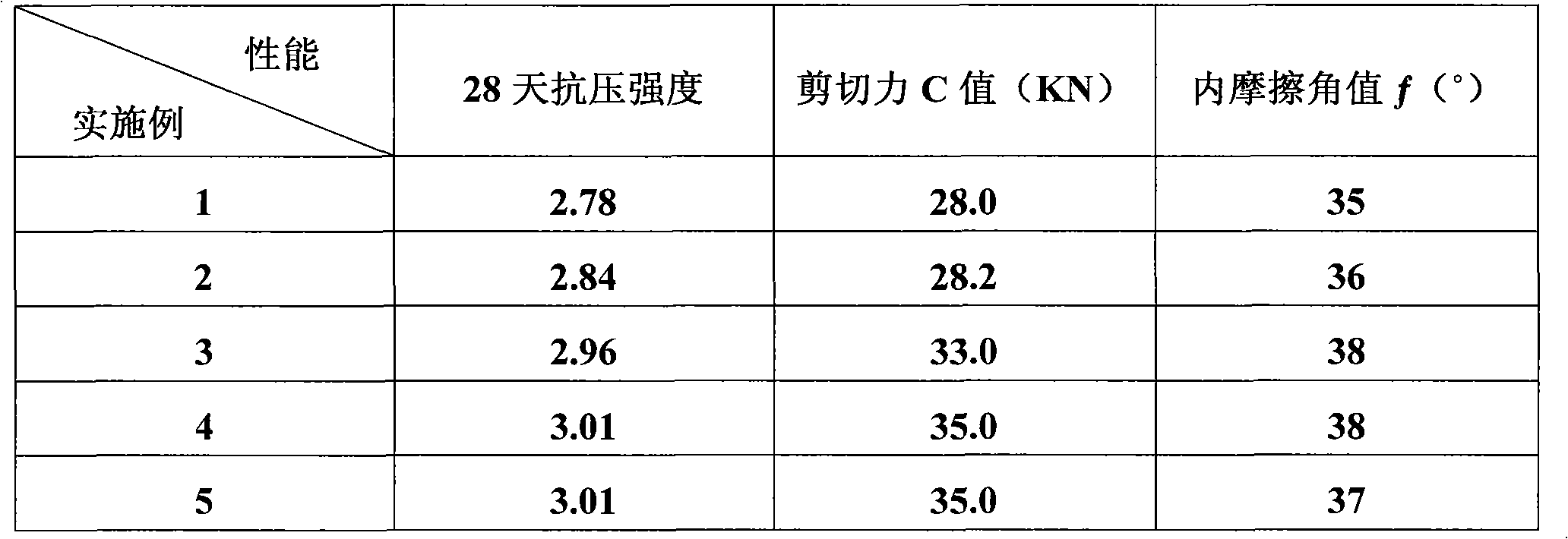

[0028] Table 1

[0029]

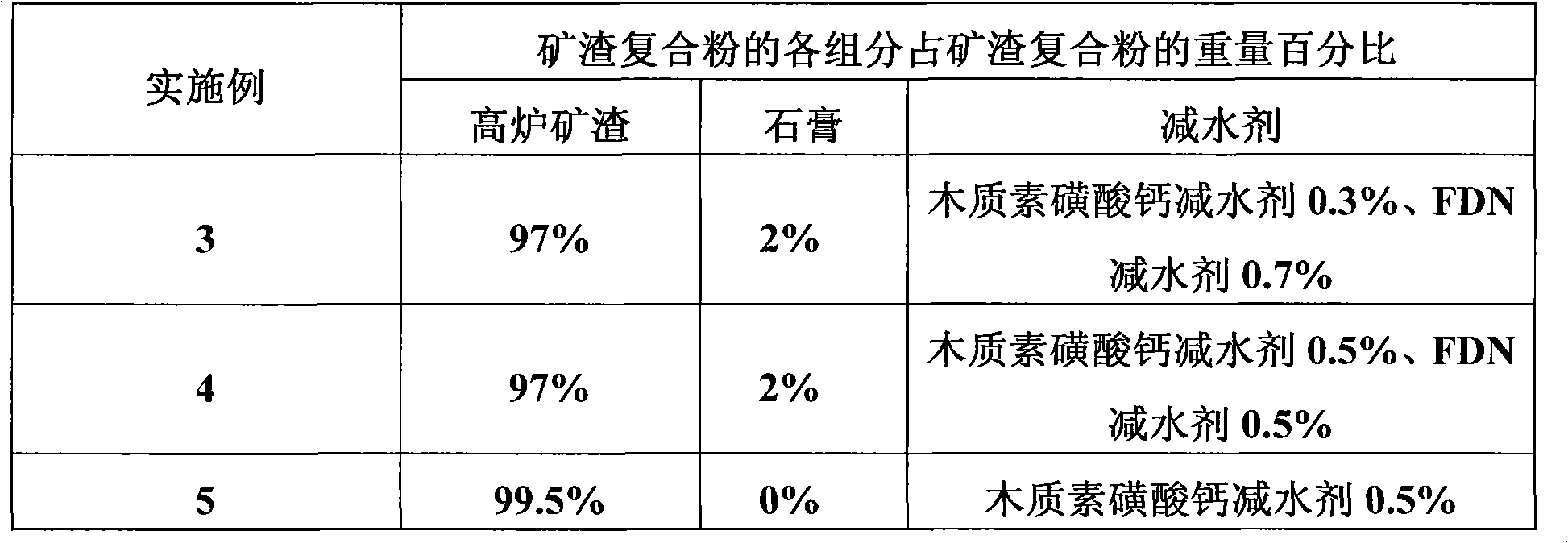

[0030] Table 2

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear force | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com