Hydrophobic solution, hydrophobic glass for vehicle and manufacturing method thereof

A technology of hydrophobic glass and aqueous solution, applied in the coating and other directions, can solve the problems of easy detachment of the hydrophobic film layer, affecting the hydrophobicity of the hydrophobic glass, etc., and achieve the effects of improved safety performance, good hydrophobic performance, and guaranteed vision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

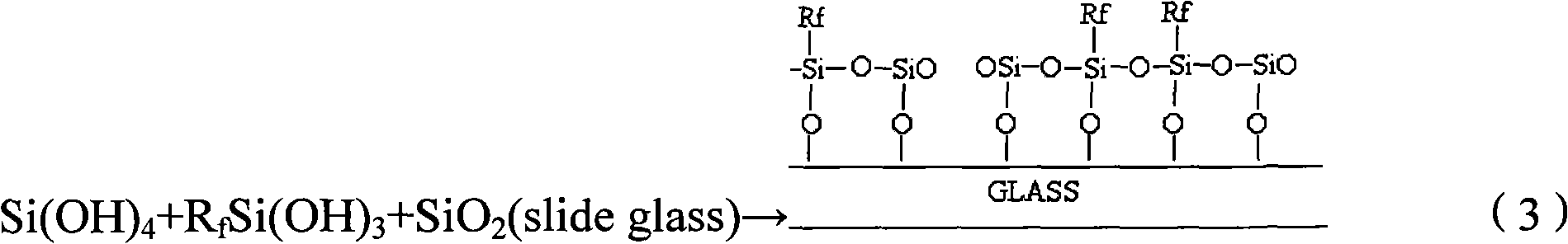

[0034] 1. Configuration of hydrophobic solution

[0035]According to the volume ratio of 10% heptadecafluorodecyltrimethoxysilane, 10% ethyl orthosilicate, and 80% propanol, the A solution is configured; according to 0.8% hydrochloric acid, 2.0% stabilizer (containing 0.2% glacial acetic acid), The volume ratio of 97.2% propanol is used to configure solution B; then the solutions A and B are mixed in equal volumes, stirred evenly and allowed to stand for 10 hours to obtain a hydrophobic solution. The volume composition of the hydrophobic solution is: 5% heptadecafluorodecyltrimethoxysilane, 5% tetraethyl orthosilicate, 88.6% propanol, 0.4% hydrochloric acid, and 1.0% stabilizer.

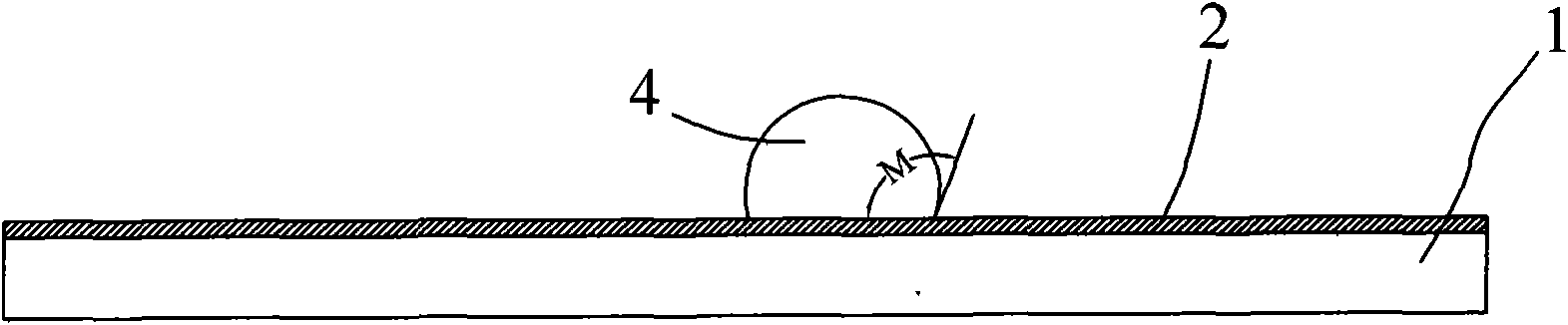

[0036] 2. Preparation process of hydrophobic glass

[0037] After the glass cleaned by the glass cleaning machine is dried by the infrared dryer, a uniform and dense film layer is formed on the glass surface by spraying with Iwata spray gun in Japan, and then heat-treated on the drying line at 80-10...

specific Embodiment 2

[0038] 1. Configuration of hydrophobic solution

[0039] Configure C solution according to the volume ratio of tridecafluorooctyltriethylsilane 4%, 2% orthosilicate, and 94% ethanol; configure the solution according to the volume ratio of 0.2% acetic acid, 4.0% stabilizer, and 95.8% ethanol D: Mix the C and D solutions in equal volumes, stir evenly and let stand for 2 hours to obtain a hydrophobic solution. The volume composition of the hydrophobic solution is: 2% trifluorooctyl triethylsilane, 1% methyl orthosilicate, 94.9% ethanol, 0.1% acetic acid, 2.0% stabilizer (containing 0.1% glacial acetic acid).

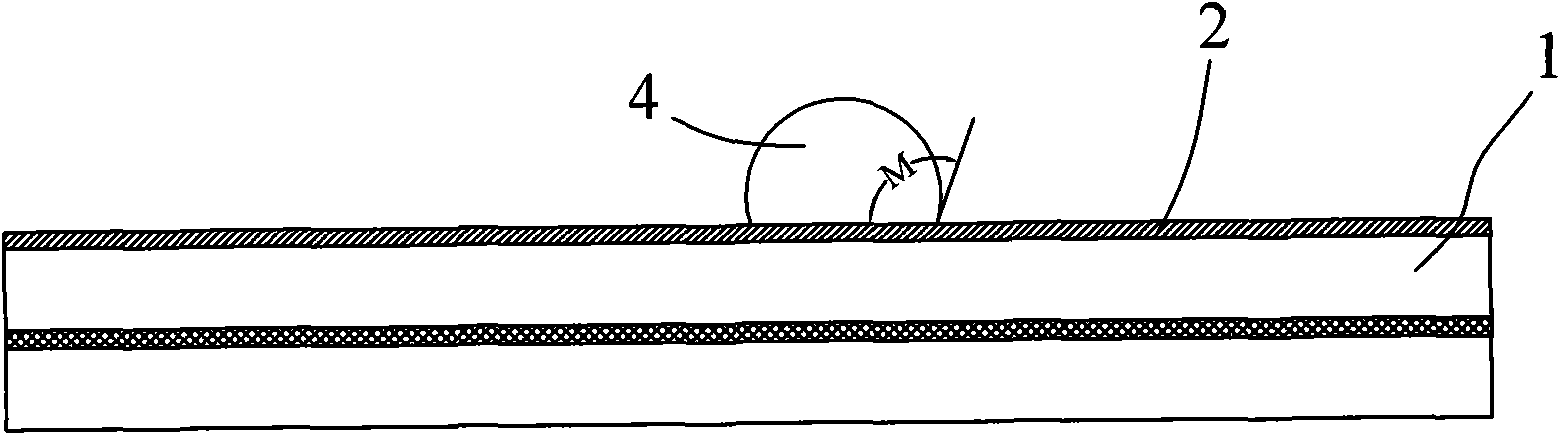

[0040] 2. Preparation process of hydrophobic glass

[0041] After the glass cleaned by the glass cleaning machine is dried by the infrared dryer, a uniform film layer is deposited on the surface of the glass by the method of roller coating machine roller coating, and heat treatment is carried out on the drying line at 150-160 °C after self-leveling After 20 minutes, a hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com