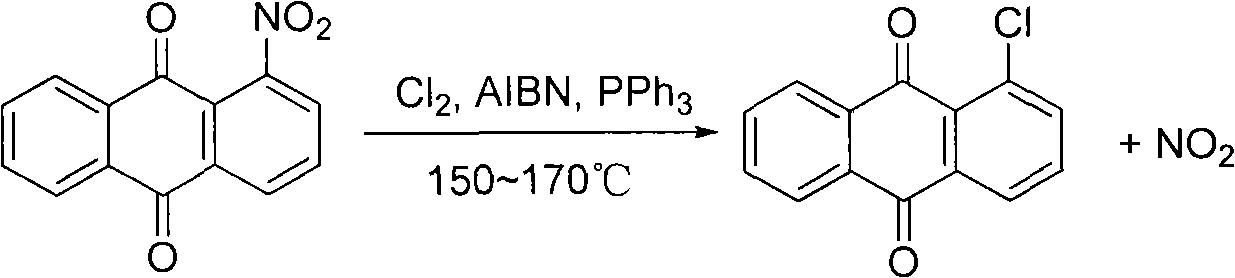

Method for synthesizing 1-chloroanthraquinone through direct chlorination of chlorine gas

A technology of chloranthraquinone and chlorine gas, applied in chemical instruments and methods, preparation of organic compounds, preparation of quinones, etc., can solve the problems of high reaction temperature, simplify the operation process, reduce waste water discharge, and improve the level of green dye production technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now taking the sieve tray tower as an example, non-limiting examples are described as follows:

[0028] Add the composite chlorination initiator (azoisobutyronitrile: triphenylphosphine=1: 1w / w) of 0.2% azoisobutyrocyanide and triphenylphosphine to the 1- In nitroanthraquinone, heating to 170°C makes it melt into a light brown liquid with low viscosity. Add dropwise from the upper part of the sieve plate type chlorination reaction tower to a reaction tower with a length of 2000mm and a diameter of 100mm, which is provided with ten layers of sieve plates, and the rate of dropping is 3kg / h. The sieve plate acts as a distributor to fully disperse the liquid 1-nitroanthraquinone. At the same time, the chlorination reagent composed of chlorine and nitrogen (chlorine: nitrogen = 70:30v / v) is introduced from the bottom of the tower and distributed through the sieve plate. After fully dispersed, the rate of feeding is 120L / h, chlorine gas and 1-nitroanthraquinone are chlorinat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com