Deep foundation pit support process

A deep foundation pit support and deep foundation pit technology, which is applied in the direction of foundation structure engineering, sheet pile walls, excavation, etc., can solve the problems of unsatisfactory reinforcement effect of weak soil, impossible construction, limited anchoring force, etc., to reduce the underground Effects of space resource pollution, fast construction speed, saving materials and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

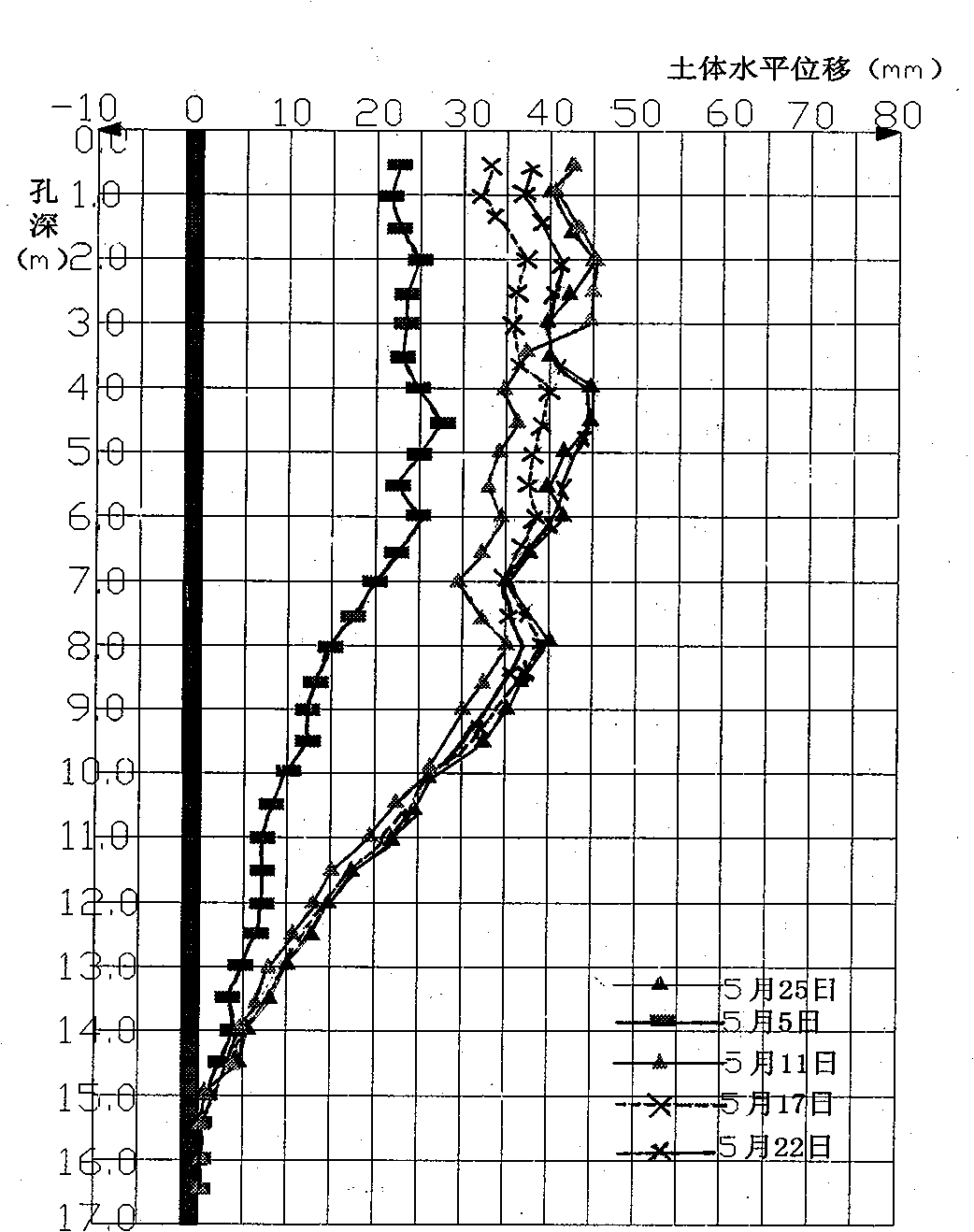

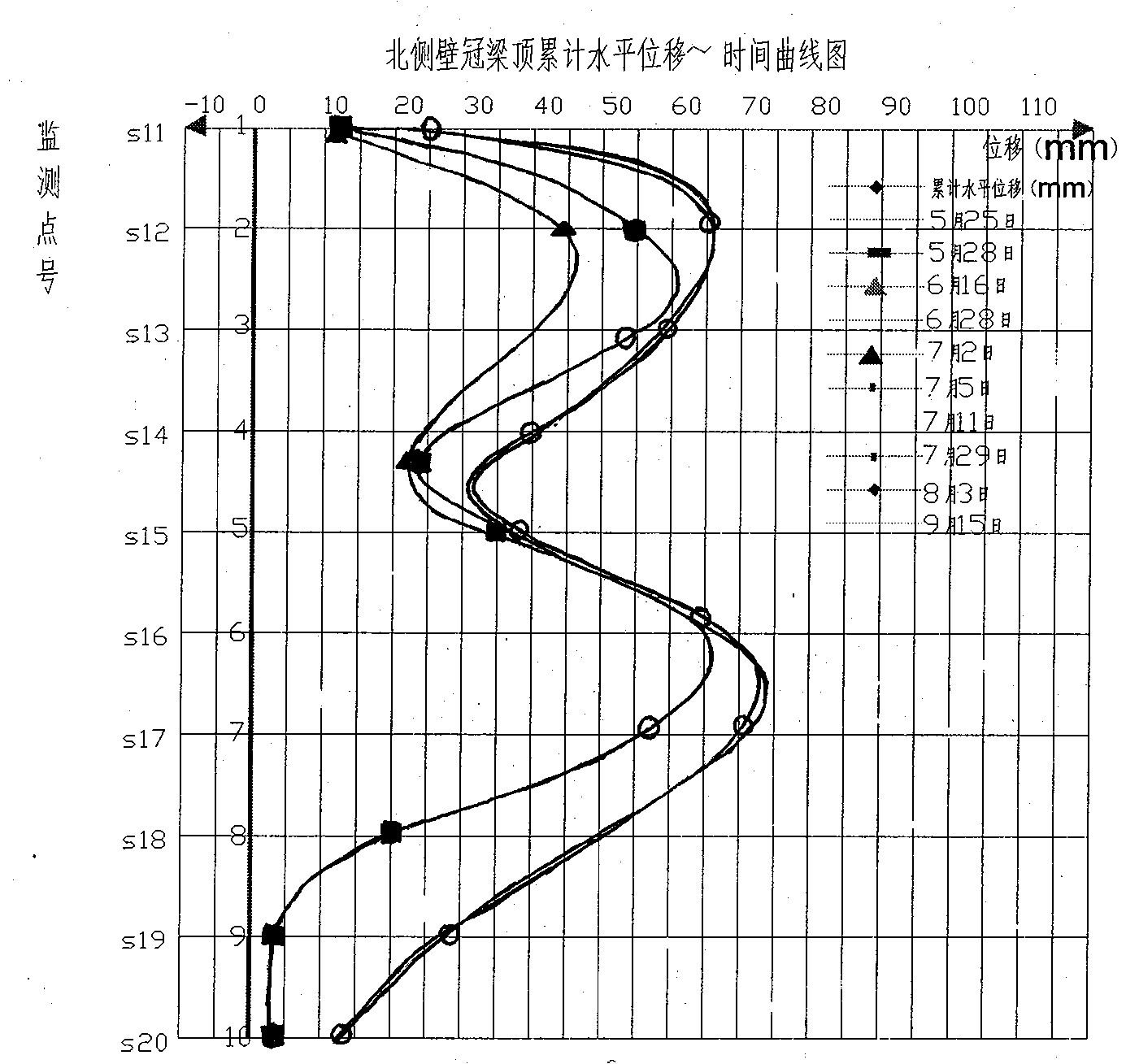

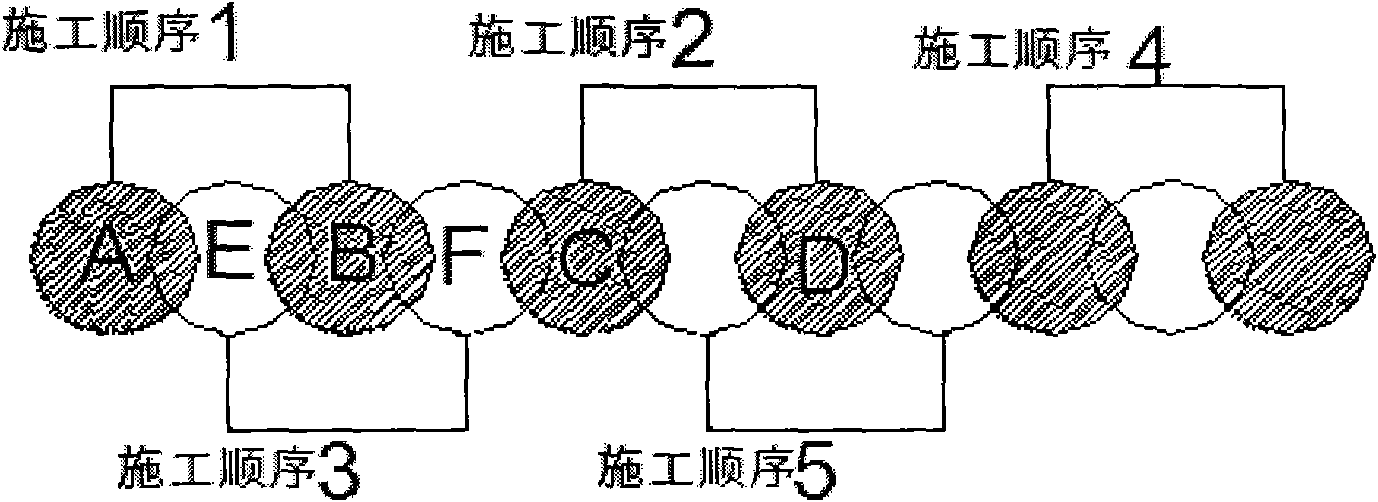

[0032] Effect analysis of the application of multi-directional rotary jet mixing and stiffening combined pile support technology in the Yufeng Square foundation pit project:

[0033] First of all, the general situation of the project and the surrounding environment are as follows: Yufeng Plaza is located on the south side of Qingnian Middle Road in Nantong City, adjacent to Nantong Third People’s Hospital in the west, Limin Building, Sande Hotel and Buildings 1# and 2# of Chengnan New Village in the south. The location is Duanjiaba Vegetable Market. The building is mainly composed of a 27-story high-rise building, a three-story podium building and a two-story basement. The first floor is an underground shopping mall, and the second floor is a parking garage and equipment floor. The structure of the high-rise building is a shear wall structure, and the highest point of the building is about 98 meters. The estimated standard value of the maximum column foot angle internal force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com