Passive acoustic detecting and positioning method for double-basic matrix data fusion power station boiler four-tube leakage

A technology for data fusion and power plant boilers, which is applied in the direction of steam boilers, steam boiler accessories, steam boiler components, etc., and can solve the problems of small detection range, impossibility and low precision of acoustic matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

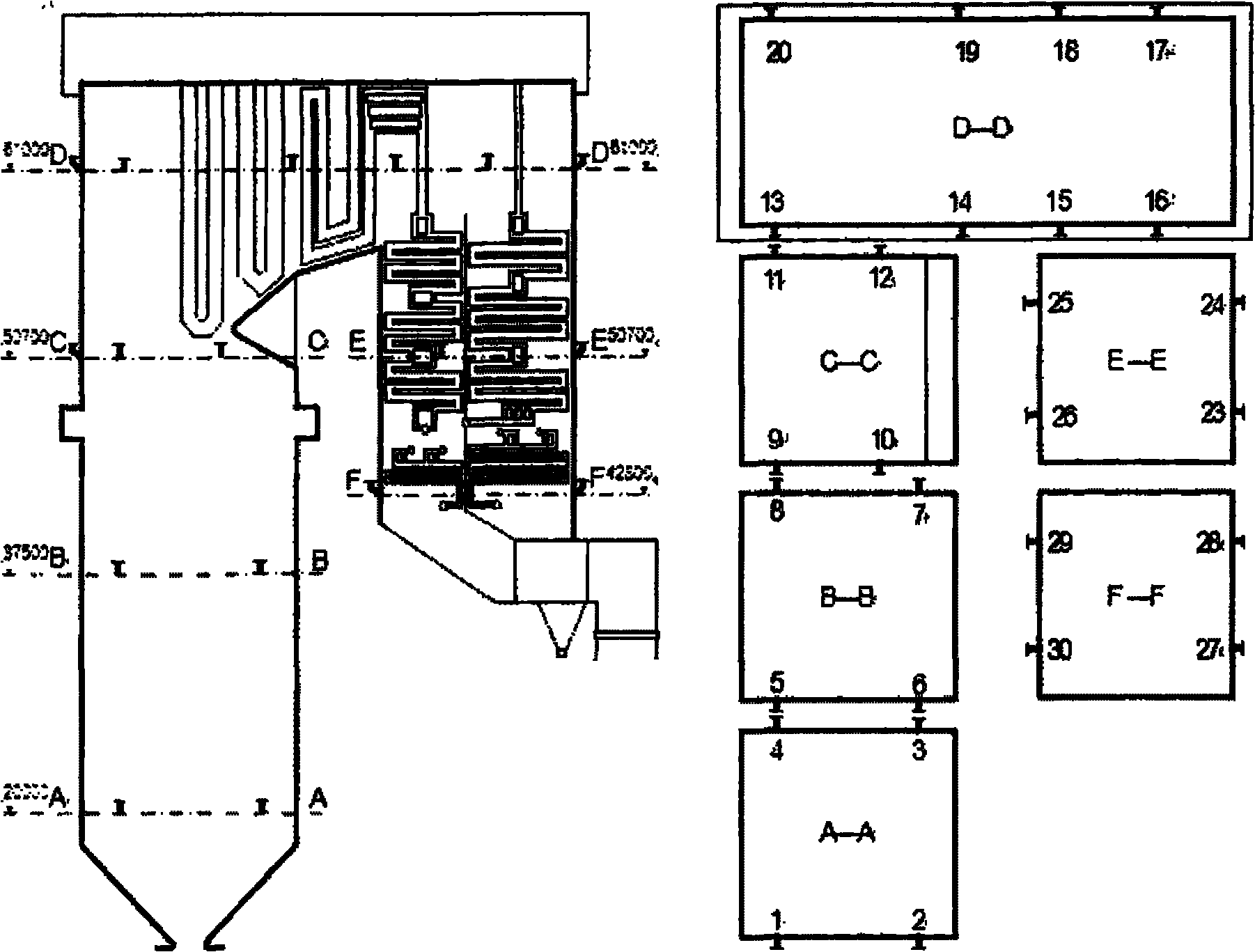

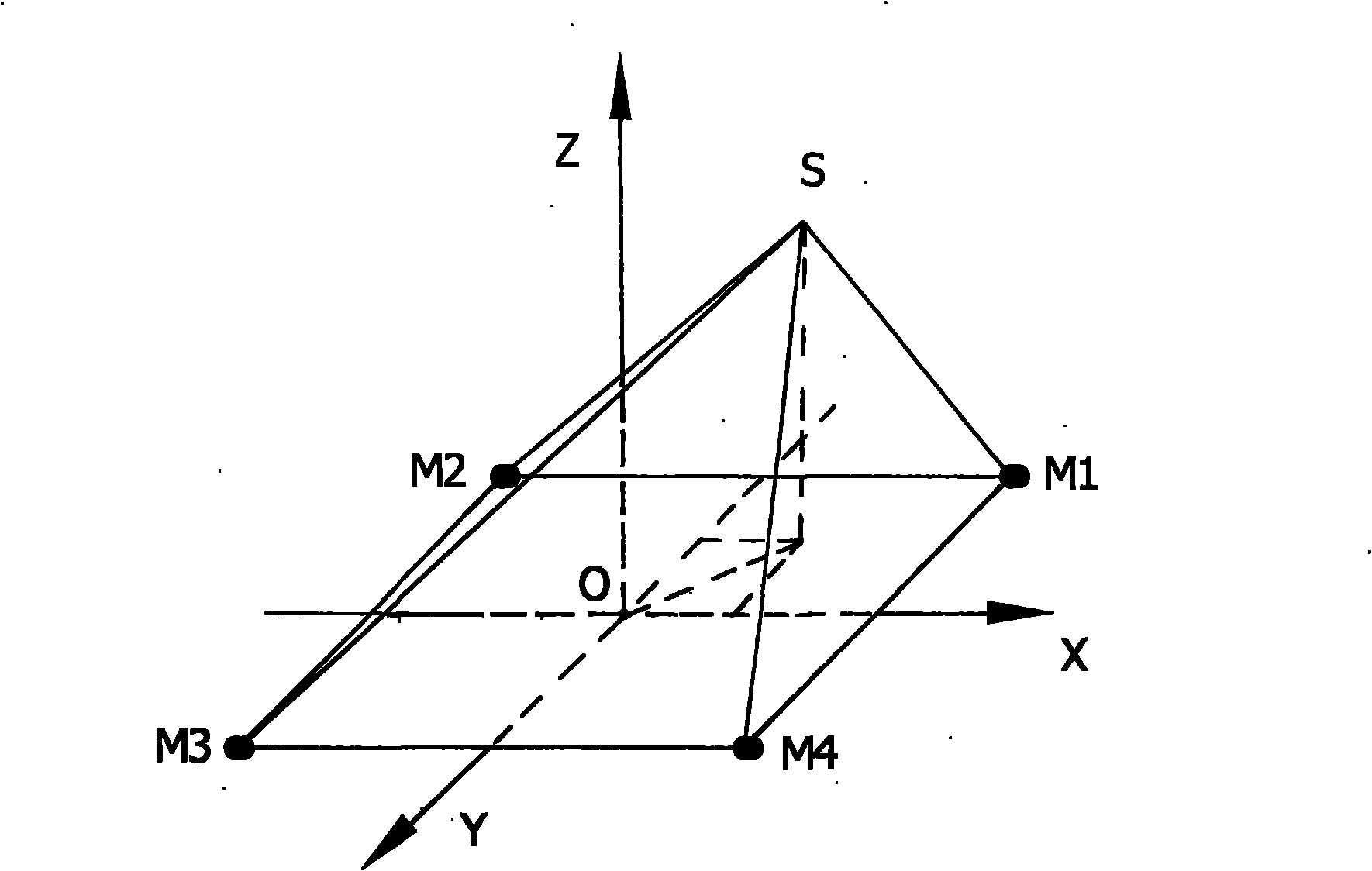

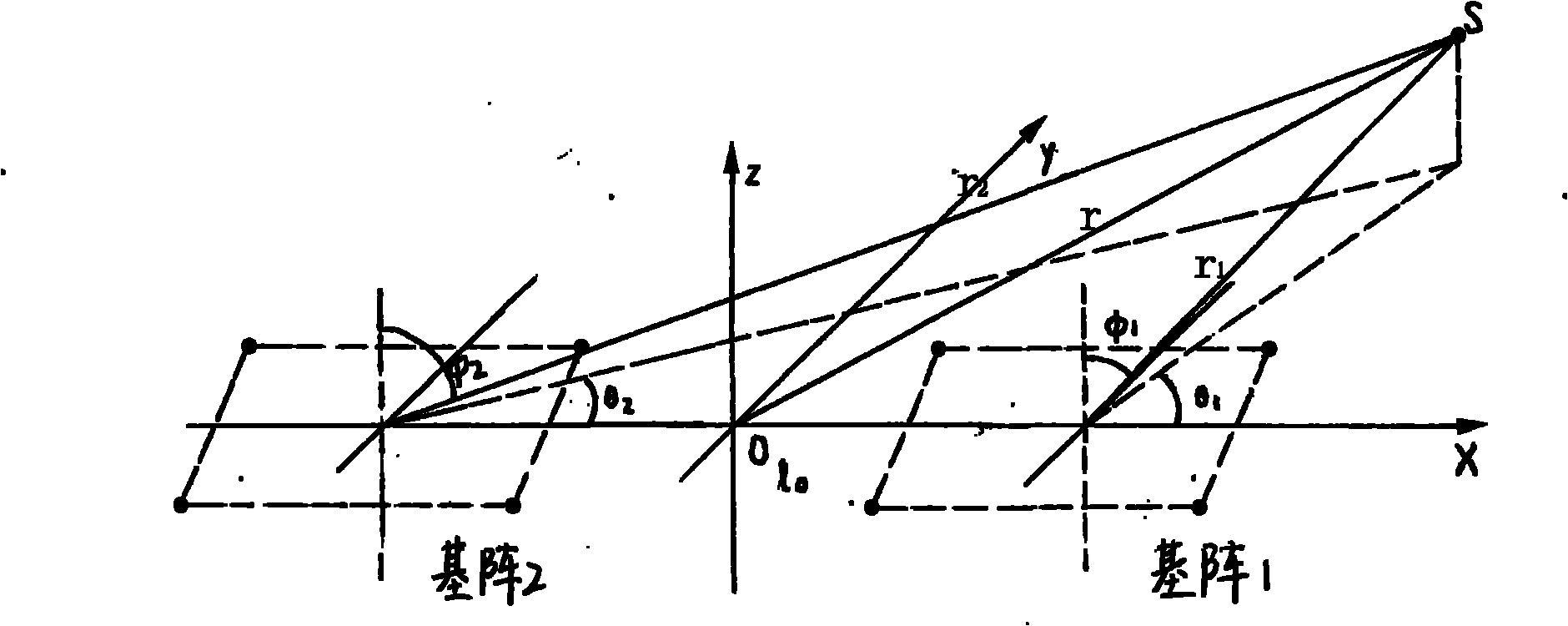

[0033] figure 1 It is a diagram of the distribution of the four-element positive square array microphone array in the boiler. exist figure 1 Among them, the SG-1025 / 17.5-M723 boiler is used, and the boiler furnace is divided into A, B, C, D, E, and F layers, with a total of 30 measuring points. According to the distribution map of the furnace measuring points, the coordinates of the center positions of any two adjacent four-element positive four-array microphone arrays are (x 1 ,y 1 ,0), (x 2 ,y 2 , 0), where y 1 =y 2 . figure 2 It is the structural diagram of the four-element square array microphone array, in which spherical coordinates are used, M 1 , M 2 , M 3 and M 4 Quaternary quadrilateral microphon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com