Photoelectric coded disk and manufacturing method and application thereof

A technology of photoelectric coding and production method, which is applied in the field of photoelectric coding discs, can solve the problems of precision, cost and reliability that cannot meet the requirements, and achieve the effect of low cost, high feasibility and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

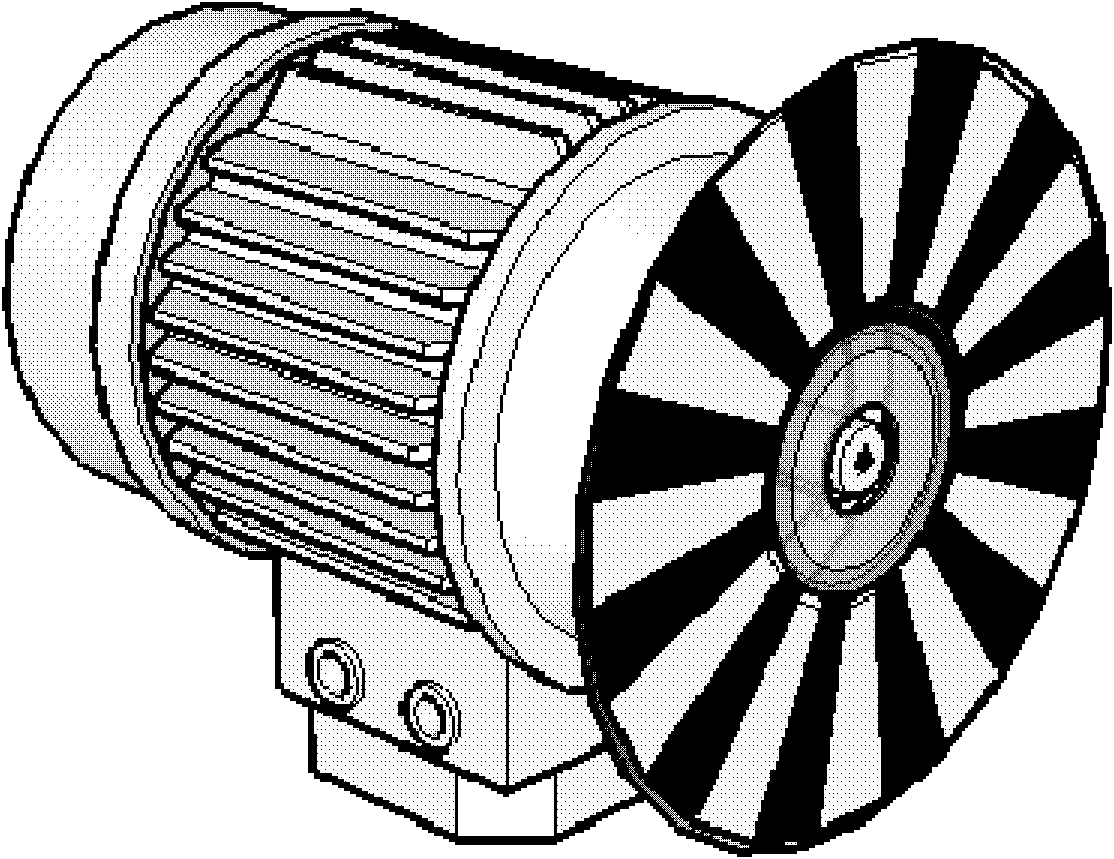

[0031] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

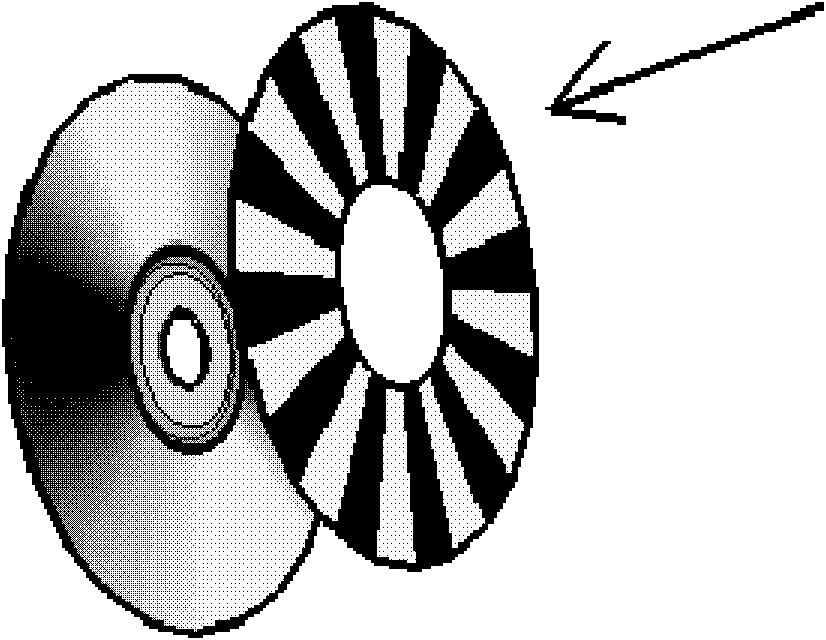

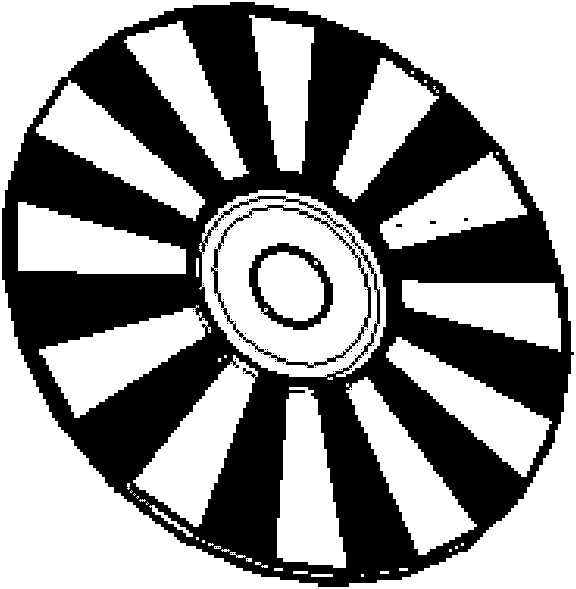

[0032] A method for making a photoelectric encoder disk, comprising the steps of:

[0033] Step 1: Make a disk base with a CD. Ordinary discs (such as CD-ROM, DVD-ROM, etc.) generally use polycarbonate (Polycarbonate, PC) as raw material, which is colorless, transparent, heat-resistant, impact-resistant, flame-retardant BI grade, and has good performance in normal use temperature. characteristics of mechanical properties. In addition, since the balance and uniformity of the disk body are fully considered during the pressing process of the optical disk, the balance and material uniformity of the code disk are well guaranteed when the optical disk is used as the disk base of the code disk.

[0034] Step 2: Draw and print to generate a raster disk. The present invention utilizes the polygonal drawing function of design software (such as AutoCAD, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com