Pre-tightening force dynamic monitoring system for pre-stressed anchor bar strengthening project

A dynamic monitoring and prestressing technology, which is applied in the direction of measuring the force by measuring the frequency change of the stressed vibrating element, can solve the problems of affecting the test accuracy, narrow application range, and complicated test devices, so as to improve stability and reliability. Sexuality, easy popularization and promotion, and considerable commercial prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

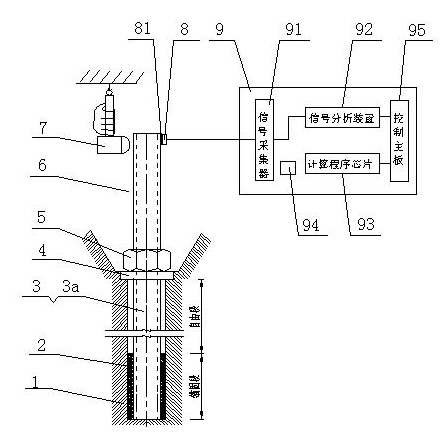

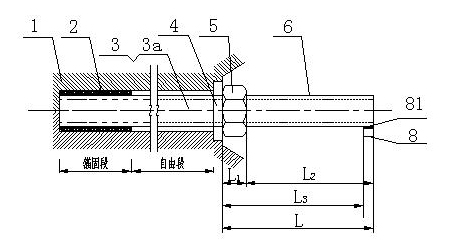

[0020] ①The construction personnel set out the construction according to the design drawings of the prestressed threaded steel anchor 3a support structure, and determine the retaining wall, the pile base line, the hole positions of each anchor hole and the inclination angle of the prestressed threaded steel anchor 3a, Then install the threaded steel bar 3. The construction process of the prestressed threaded steel anchor rod 3a is: drilling → installation of the threaded steel bar 3 → grouting to form the anchor body 2 → tension locking → anti-corrosion protection. The outer end of the prestressed threaded steel anchor rod 3a is provided with an exposed section 6 as required. The length of the exposed section 6 must be reserved when the threaded steel bar 3 is stretched. In order to reduce the influence of the shear effect on the accuracy of the calculation equation to within 3% , the length of the exposed section 6 is required to be the length L from the top surface of the nu...

Embodiment B

[0024] ① After the construction operation, the process of transforming the threaded steel bar 3 into the prestressed threaded steel bar anchor 3a is completed. According to the requirements, the length of the upper exposed section 6 of the prestressed threaded steel bar anchor 3a should be greater than 5 times the diameter of the prestressed threaded steel bar anchor 3a. , the threaded steel bar 3 with a diameter of 22-32 mm is generally used in the prestressed threaded steel anchor bar 3a in the support structure, and Take fine-rolled rebar as an example, its thread type is M34*3.0, the height of supporting nut 5 is 72mm, the shape is hexagonal, the distance across sides is 62mm, the length of exposed section 6 is greater than 160mm, and the length of exposed section 6 in this embodiment is set to 165mm .

[0025] ②The top of the exposed section 6 of the prestressed threaded steel anchor rod 3a is fixedly connected with the acceleration sensor 8 through the magnetic suction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com