Multistage moving bed biomembrane reactor

A moving bed biofilm and reactor technology, applied in water/sewage multi-stage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of accumulation, not easy to realize, etc., and achieve high treatment efficiency , the structure is simple, the effect of improving the efficiency of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

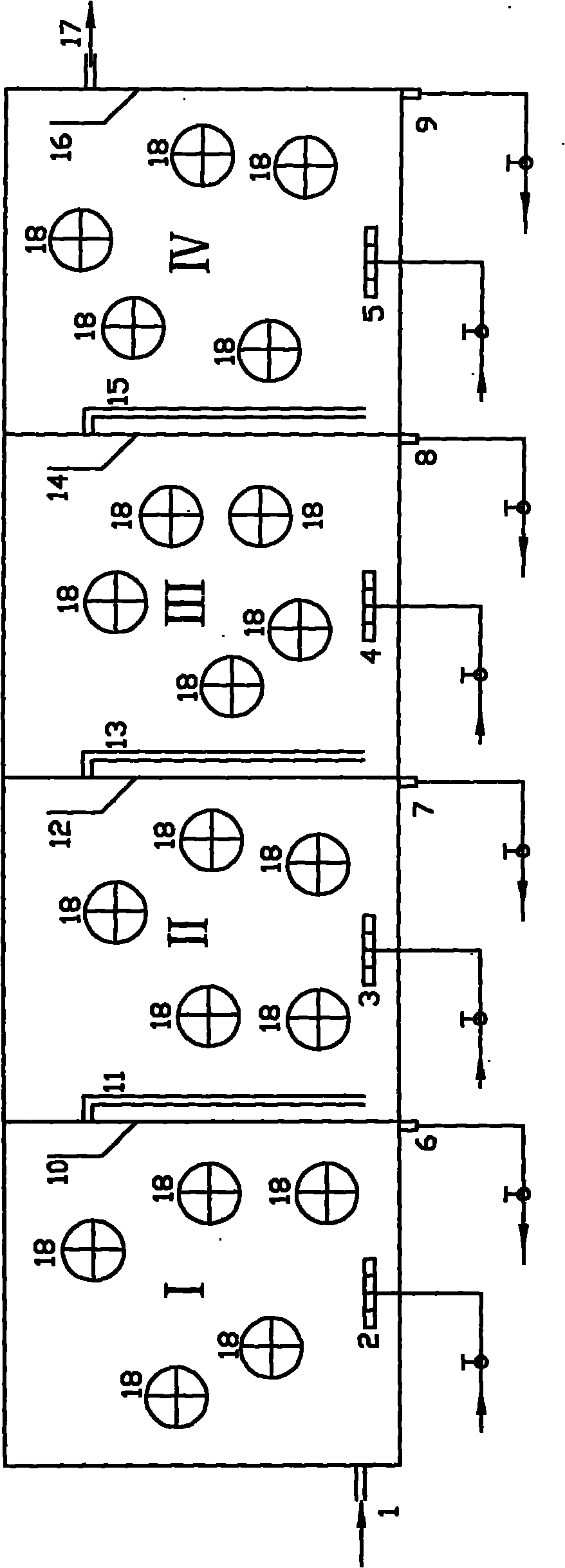

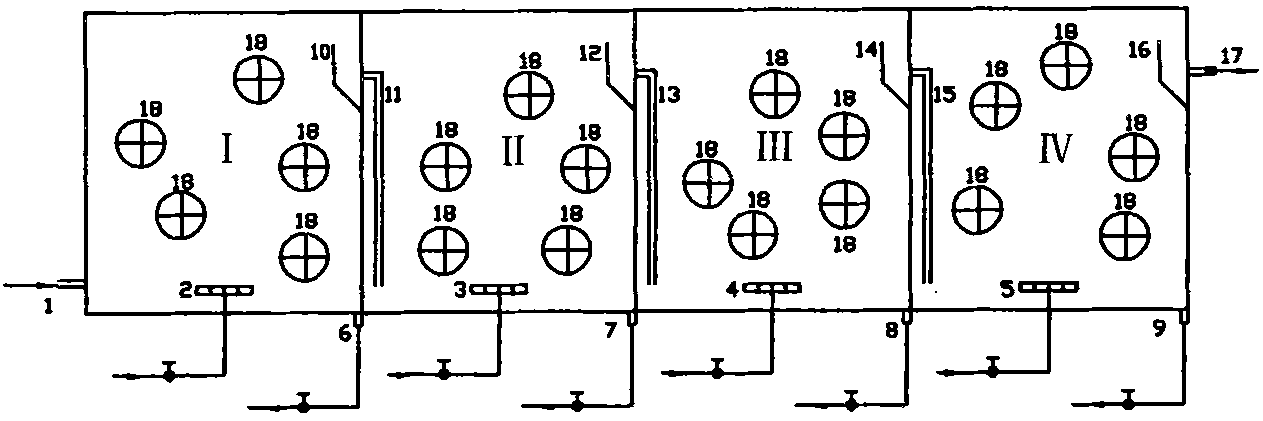

[0023] figure 1 A schematic diagram of the structure of a multi-stage moving bed biofilm reactor is shown. In the figure, the reactor includes 4 aeration tanks, each aeration tank is separated by a plexiglass plate with a smooth surface. The length-to-width ratio of the aeration tank is 1:2-1:4 for domestic sewage, centering Low-concentration chemical wastewater: about 1:1, for food wastewater: 2:1-4:1. The aeration tanks are equipped with plum-shaped aeration heads 2, 3, 4, and 5 for complete mixing and aeration. Each aeration tank is filled with a suspended carrier 18, and each aeration tank is equipped with microporous aeration heads and microporous aeration heads. The air heads are respectively connected to the external air pumps. Put the high-efficiency composite biological suspension carrier 18 into each aeration tank according to the filling ratio of 20%-30%. The sewage from the water inlet 1 flows into the aeration tank II through the overflow weir 10 through the draf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com