Sludge stirring and granulating rotary drying device

A stirring granulation and rotary drying technology, which is applied in the field of machinery, can solve the problems of uneven feeding of sludge, easy sticking of sludge into large pieces, and inability to adjust the direction of flue gas flow, etc., and achieve the effect of uniform sludge particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

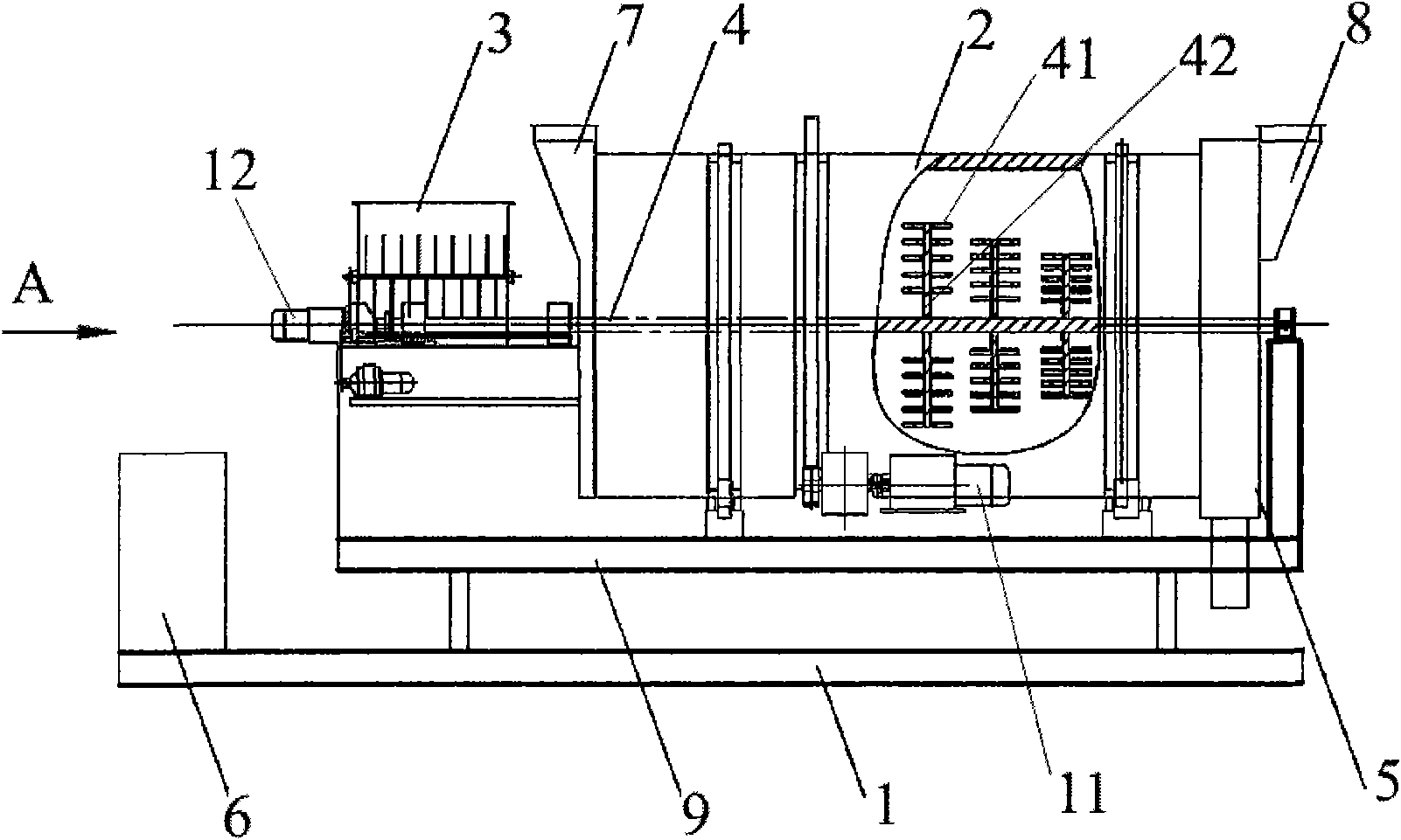

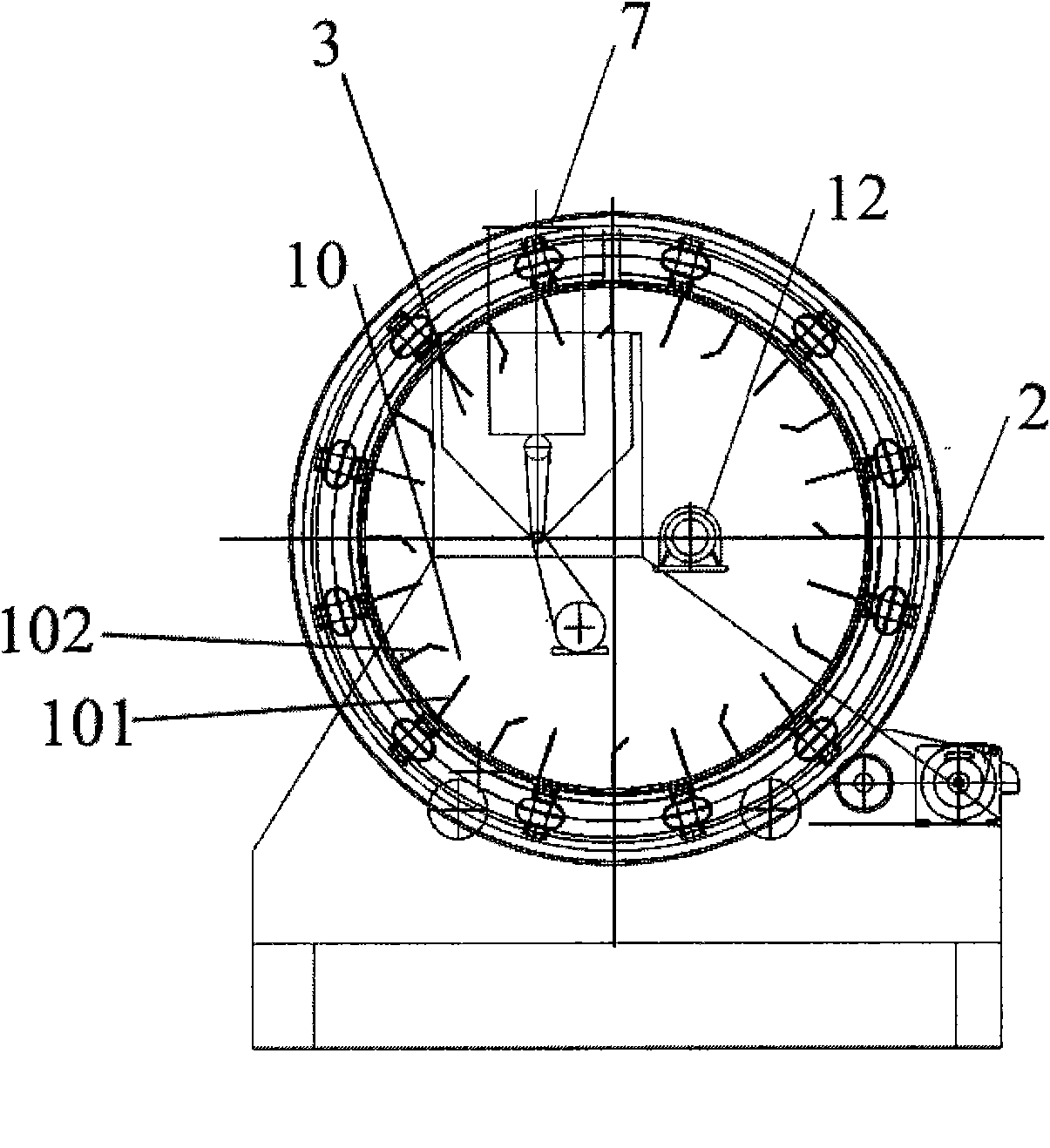

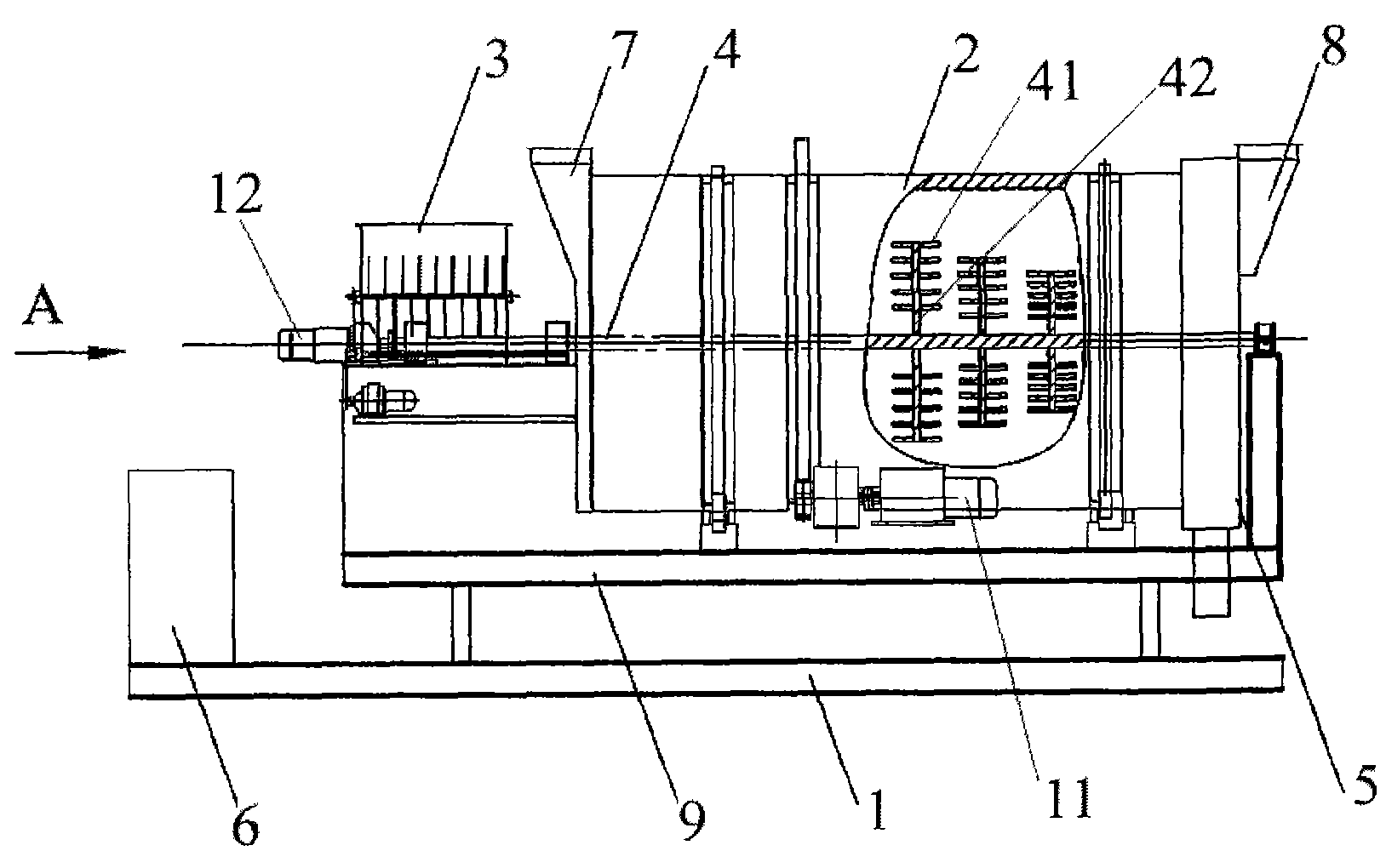

[0016] Such as figure 1 with figure 2 As shown, a sludge stirring and granulating rotary drying device of the present invention consists of a base 1, a support 9, a drum 2, a feeding device 3, a stirring shaft 4, a discharge box 5, a stirring shaft driving device 12 and a drum driving device 11 Composition, wherein, the support 9 is arranged on the base 1, one end of the support 9 is connected with the base 1 through a hinge mechanism, a lifting device is arranged between the other end of the support 9 and the base 1, and the The feeding device 3 and the stirring shaft driving device 12 are all arranged on the bracket 9, and the two ends of the drum 2 are respectively provided with connecting cylinders, a sealing device is arranged between the drum 2 and the connecting cylinder, and the connecting cylinder is fixedly arranged on the bracket 9 , the drum driving device 11 is arranged on the bracket 9, the drum driving device 11 is connected with the drum 2, the two ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com