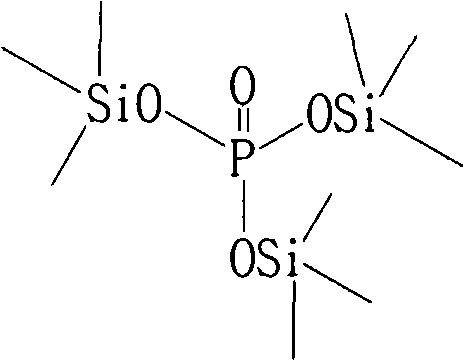

Synthesis method of tris(trimethylsilyl) phosphate

A technology based on a trimethylsilyl group and a synthesis method, which is applied to phosphorus organic compounds, electrochemical generators, electrical components, etc., can solve the problems of long reaction time, high reaction temperature, and low product yield, and achieves easy control of the reaction. , The effect of high reaction yield and good product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

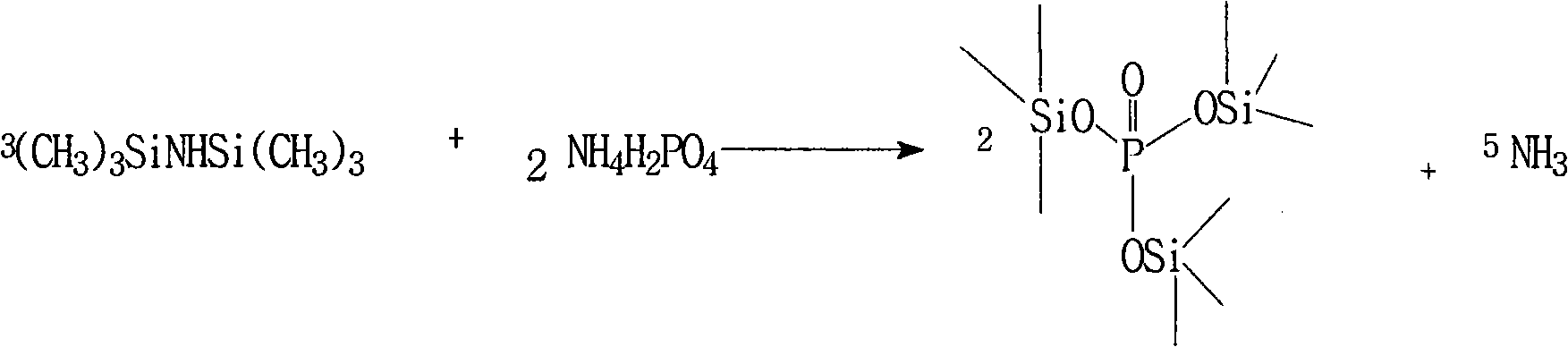

Method used

Image

Examples

Embodiment 1

[0024] A 500ml three-necked flask is equipped with an electric stirrer, a reflux condenser, and a thermometer. Add 58g (0.5mol) of ammonium dihydrogen phosphate and 320ml (1.5mol) of hexamethyldisilazane, and heat and stir at 120°C for 3 hours. After the reaction was finished, the reflux device was changed to a fractionation device for fractionation and purification. The vacuum fractionation method was used to collect fractions at 126-128° C. / 30 mmHg to obtain 126 g of tris(trimethylsilyl) phosphate.

Embodiment 2

[0026] A 1000ml three-necked flask is equipped with an electric stirrer, a reflux condenser, and a thermometer. Add 200g (1.72mol) of ammonium dihydrogen phosphate and 590ml (1.58mol) of hexamethyldisilazane, and heat and stir at 130°C for 3 hours. After the reaction, the reflux device was changed to a fractionation device for fractionation and purification. The vacuum fractionation method was used to collect fractions at 118-119° C. / 25 mmHg to obtain 541 g of tris(trimethylsilyl) phosphate.

Embodiment 3

[0028] A 5000ml three-necked flask is equipped with an electric stirrer, a reflux condenser, and a thermometer. Add 1000g (8.6mol) of ammonium dihydrogen phosphate and 2950ml (13.6mol) of hexamethyldisilazane, and heat and stir at 100°C for 5 hours. After the reaction was finished, the reflux device was changed to a fractionation device for fractional distillation and purification. The vacuum fractional distillation method was used to collect fractions at 120-121° C. / 27 mmHg to obtain 2210 g of tris(trimethylsilyl) phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com