Impact resisting weather-proof polypropylene and preparation method thereof

A weather-resistant polypropylene and polypropylene technology, applied in the field of polypropylene modification, can solve the problems of high cost, poor fluidity and weather resistance of impact-resistant weather-resistant polypropylene, and achieve excellent fluidity, good synergy, excellent The effect of impact performance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preparation method of embodiment is:

[0029] Step 1: take each raw material by weight;

[0030] Step 2: Stir and mix polypropylene resin, polyethylene resin, antioxidant, partial coupling agent, light stabilizer, processing aid and colorant in a mixer for 5 minutes to obtain a mixture;

[0031] Step 3: Mix the remaining coupling agent and filler in a high-speed mixer (rotating at 1200 RPM) for about 6 minutes according to the proportion to obtain a mixture;

[0032] Step 4: Extrude and granulate the mixture of step 2 and step 3 respectively from the main feeding port and the side feeding port of the twin-screw extruder to finally obtain the product. The processing temperature is 200°C, the screw speed is 450RPM, the length-to-diameter ratio of the screw is 32, the temperature control zone of the extruder is zone 11, and the side feeding port is located in zone 4.

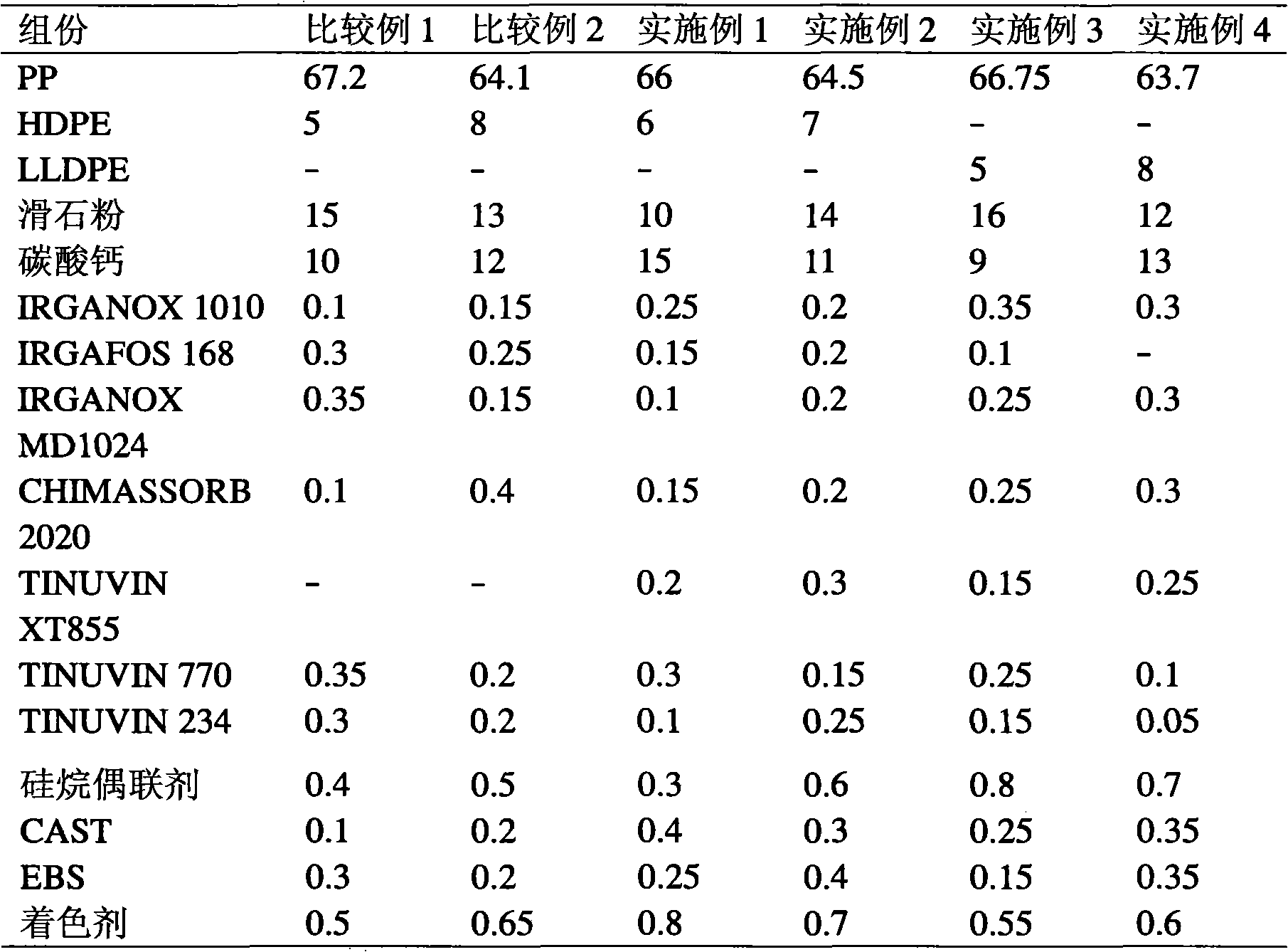

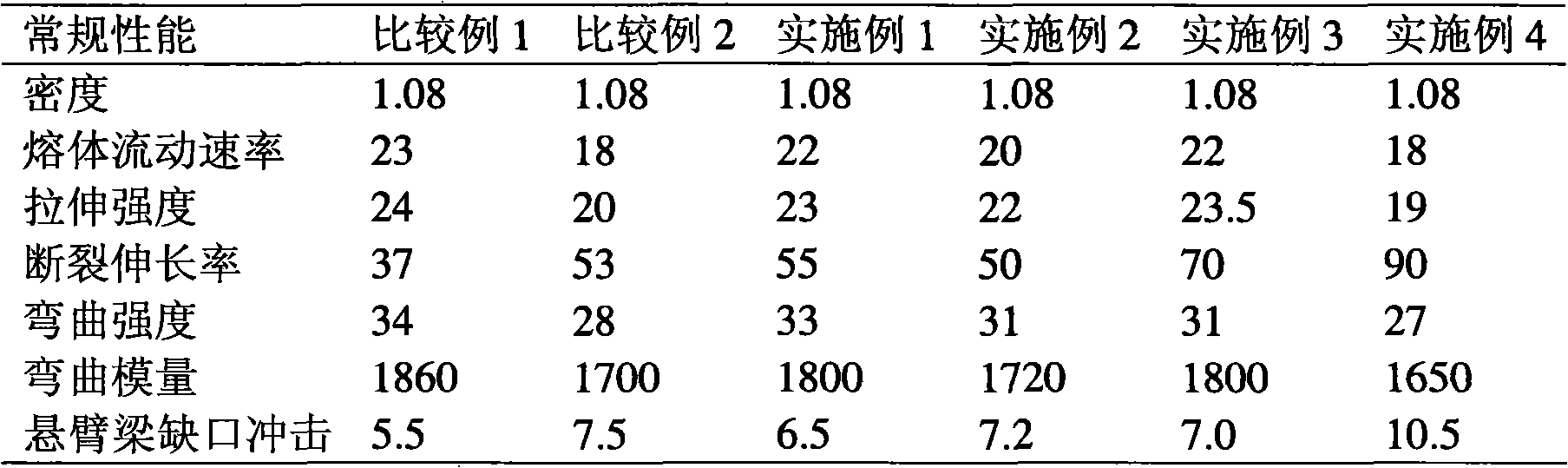

[0033]The concrete composition of comparative example and embodiment is listed in Table 1, and conv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com