SDS-PAGE (Sodium dodecyl sulfate-polyacrylamide gel electrophoresis) rapid decoloring method and special decoloring cup thereof

A decolorizing cup and fast technology, applied in the preparation of test samples, measuring devices, instruments, etc., can solve the problems of white gel, unable to verify results, low feasibility, etc., to achieve simple operation, speed up test progress, No effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

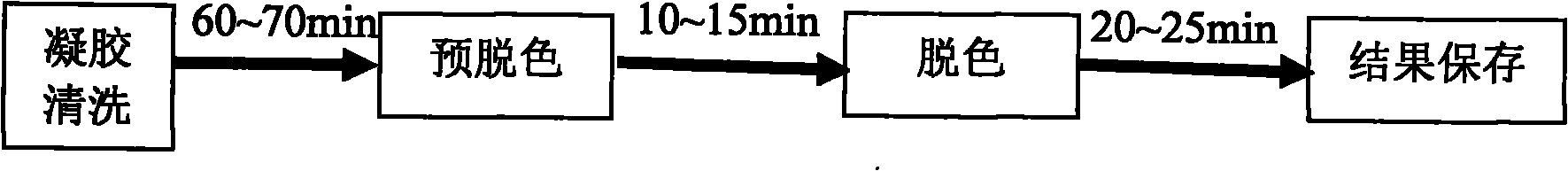

[0030] The present invention will further describe decolorization process below in conjunction with accompanying drawing:

[0031] like figure 1 Shown: decolorization method of the present invention is finished by the following steps:

[0032] 1) Gel cleaning: After electrophoresis, wash the gel 2-3 times with distilled water, deionized water or ultrapure water (tap water is not allowed);

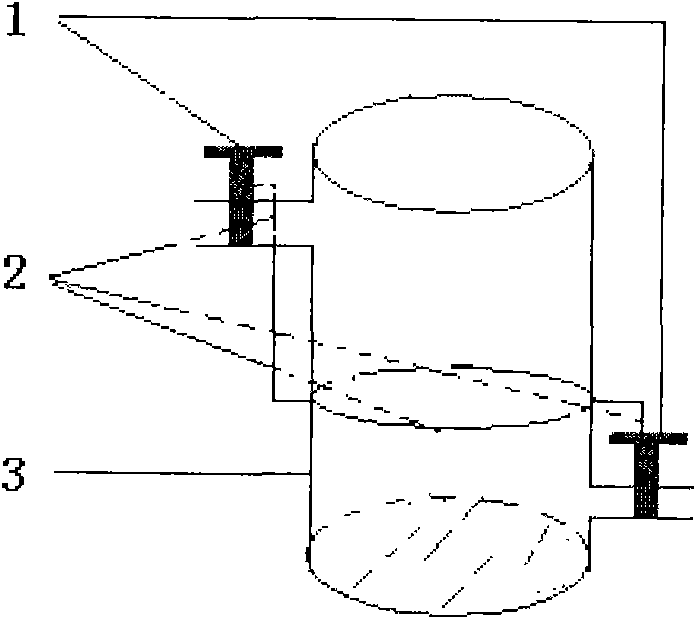

[0033] 2) Pre-decolorization: Put the gel into the decolorization cup (the structure of the decolorization cup is as follows: figure 2 As shown), add a small amount of distilled water, deionized water or ultrapure water, the water surface just submerged the gel, heat until the water in the decolorization cup (3) reaches 80°C, stop heating, release the water in the cup, repeat 2 Second-rate.

[0034] 3) Decolorization: Add enough distilled water, deionized water or ultrapure water to the decolorization cup (3), the amount of water is 2-3 times that of pre-decolorization, when heated to 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com