Test device and test method for limit heat-flow density of porous material for heat pipe

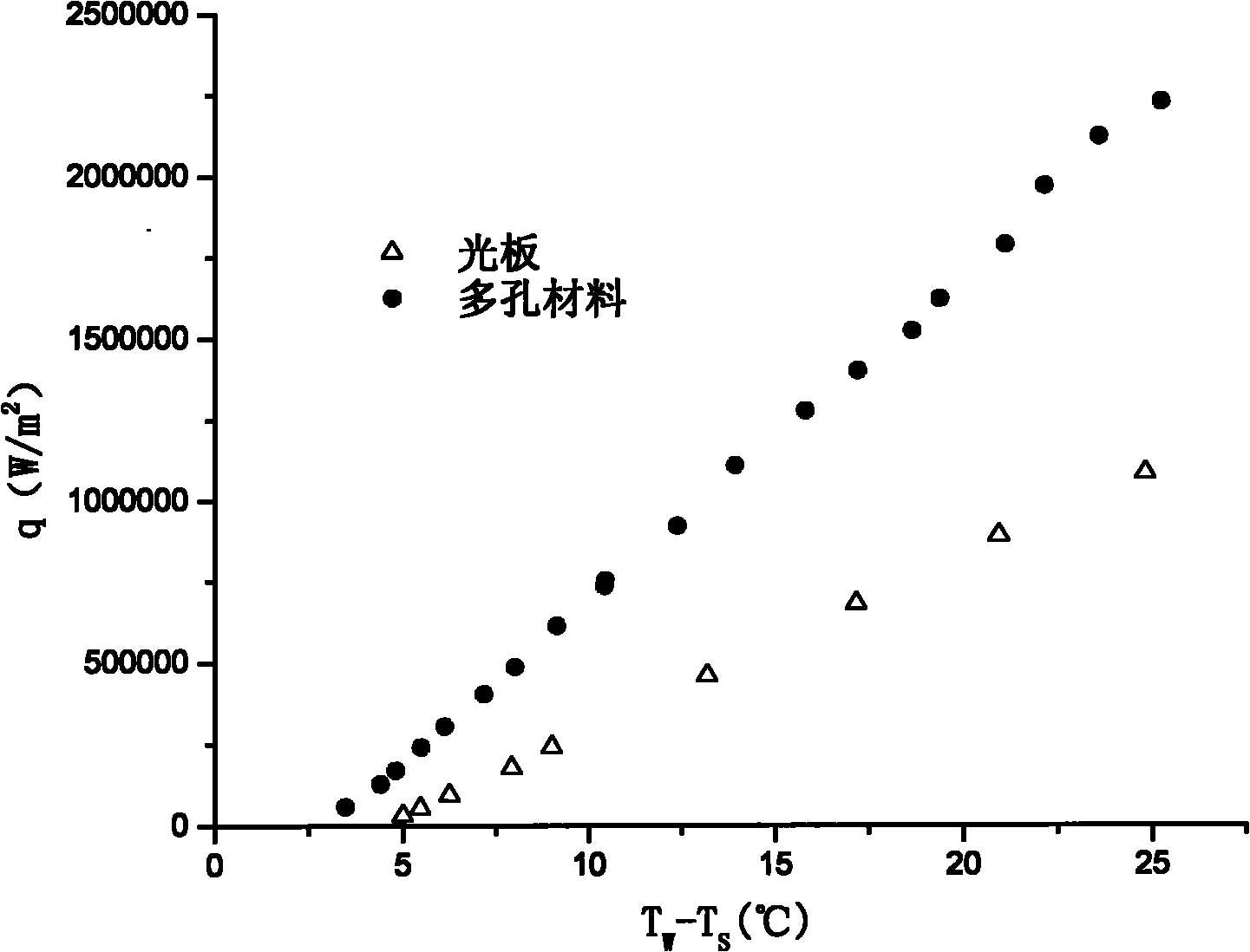

A heat flux density and testing device technology, applied in the field of heat pipe heat transfer, can solve the problems of working fluid pressure loss, small permeability, low permeability, etc., and achieve the effect of stable data and good data consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, the present invention will be further described in detail based on the embodiments.

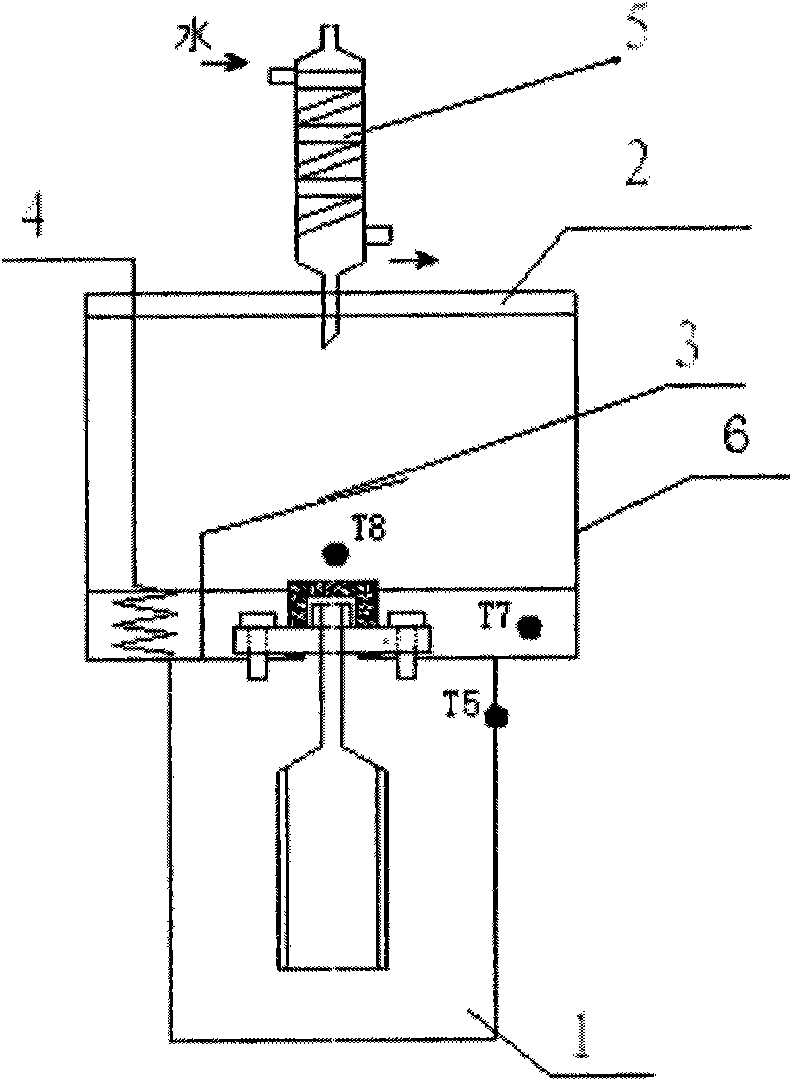

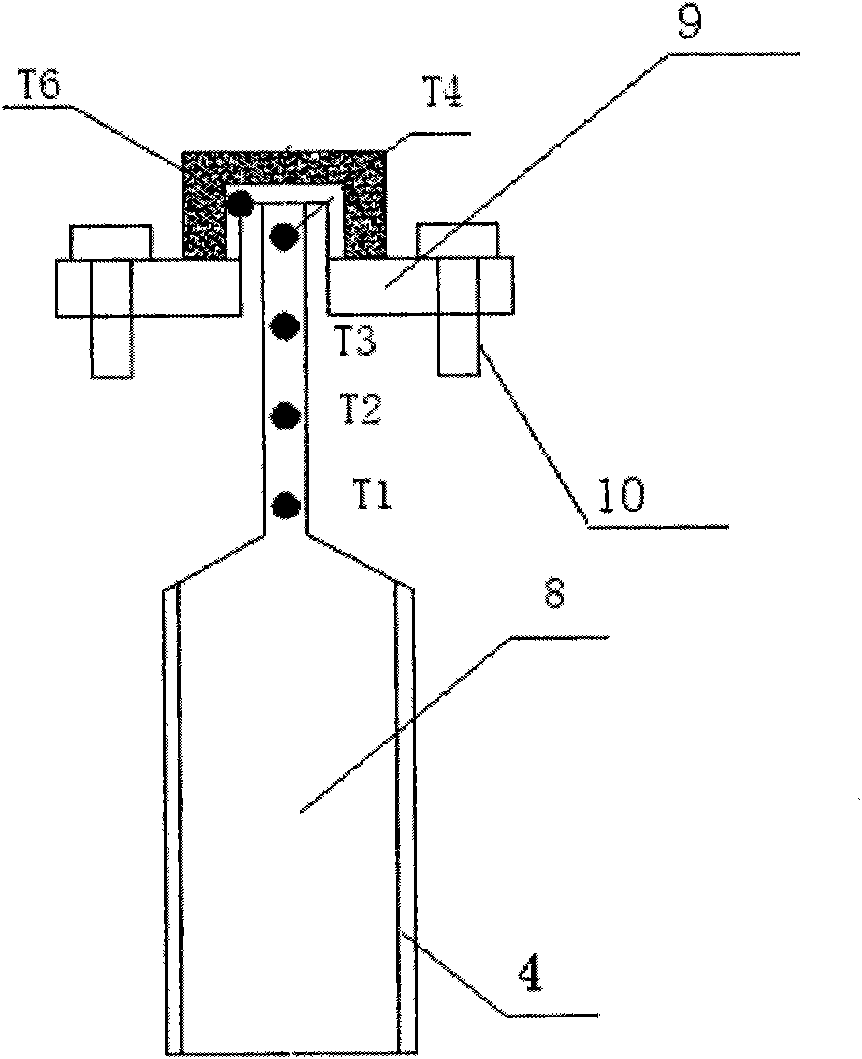

[0046] Such as figure 1 , figure 2 Shown is a testing device for the limit heat flux density of porous structural materials for heat pipes of the present invention. The device includes a thermal insulation material 1, a baffle 3, a heater 4, a condenser tube 5, a stainless steel barrel 6, a heat transfer block 7, and a thermocouple. 8 and test block 9;

[0047] The stainless steel barrel 6 is provided with a transparent heat-insulating glass cover 2, the condenser tube 5 enters the stainless steel barrel 6 through the through hole on the heat-insulating glass cover 2, the heater 4 and two thermocouples 9 (T7 and T8 respectively) are installed in stainless steel In the barrel 6, the test block 9 is fixed on the through hole at the bottom of the inner side of the stainless steel barrel 6 by screws 10. A thermocouple 9 (T6) is provided on the test block 9 and a baffle is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com