Strip-type funneling solid-liquid separator and gas lifting pulsation push flowing oxidation ditch thereof

A solid-liquid separator, solid-liquid separation technology, applied in anaerobic digestion treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Work energy consumption is too large, the structure of the solid-liquid separator is complex, etc., to achieve the effect of good effluent water quality, good denitrification and phosphorus removal effect, and reduction of production and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

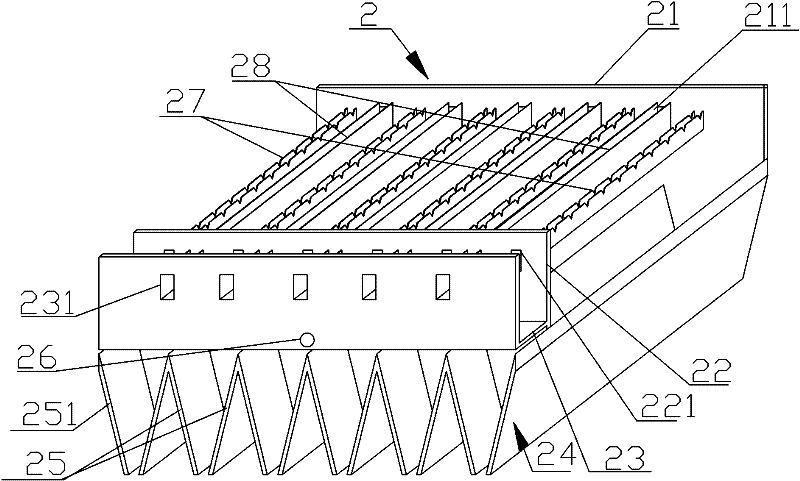

[0025] figure 1 Shown is a strip funnel-type solid-liquid separator 2, comprising a vertical end wall that is vertically connected between the walls on both sides of the oxidation ditch 1 and surrounds the clarification zone, separation zone and sedimentation zone that form the solid-liquid separation zone. It is characterized in that the above-mentioned vertical end wall includes a front end wall 22 and a rear end wall 21 parallel to it, which is close to the front end wall. The upper part of the outer side of the wall 22 is provided with a strip-shaped water collection tank 23 vertically connected between the two sides of the oxidation ditch. The water outlet 221 of the water collection weir communicates with the sump 23 provided with the drain 26; the sump 23 is a square cross-section groove. A plurality of strip-shaped overcurrent troughs 28 are interlaced with the water collection weir 27 and arranged in parallel, one end of which is the water inlet 211 protruding throug...

Embodiment 2a

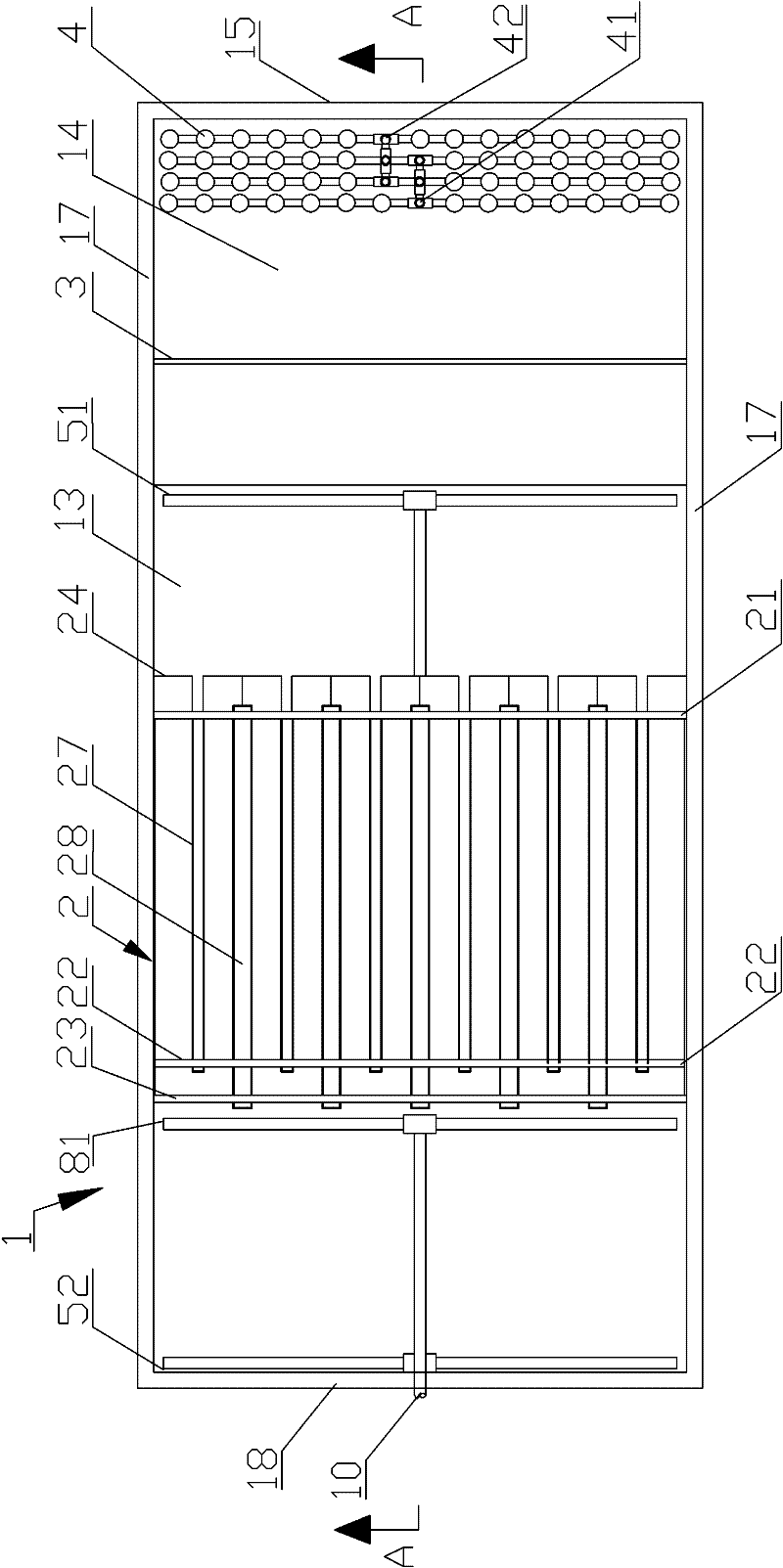

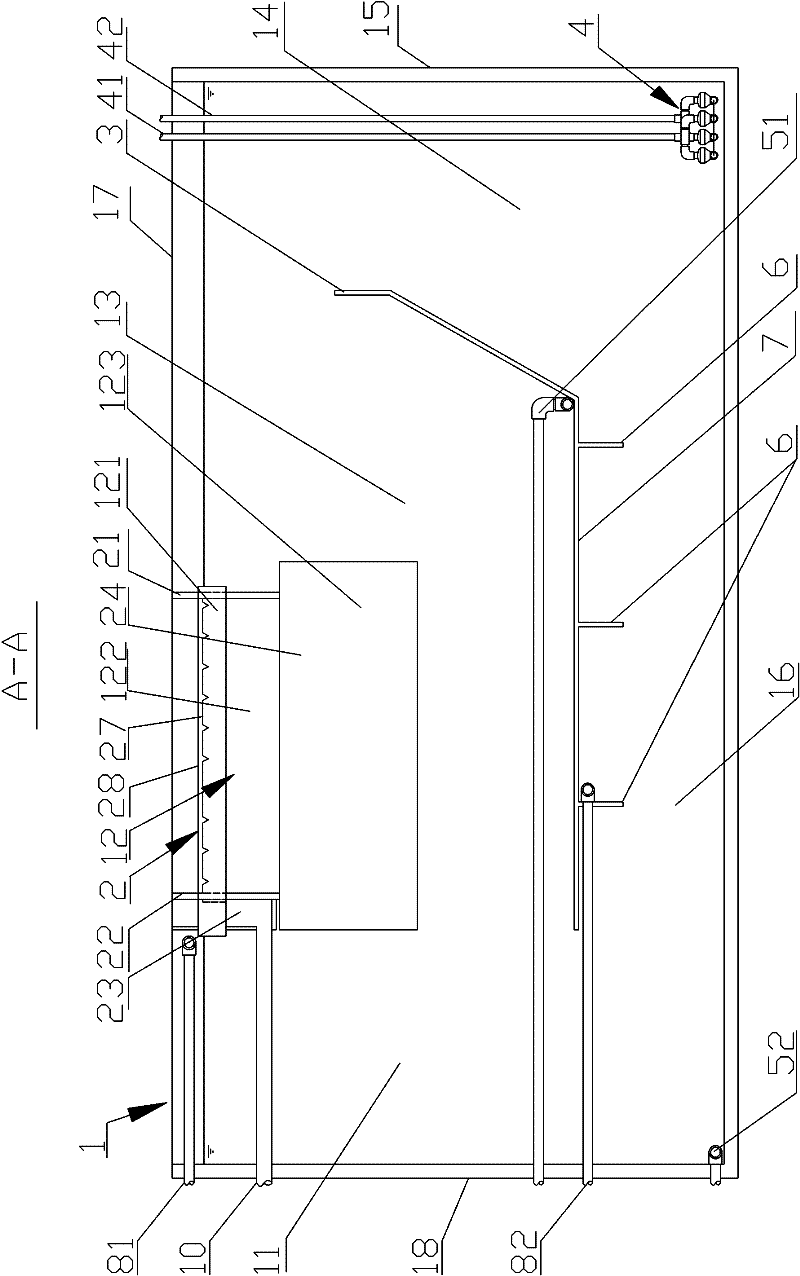

[0028] Figure 2 ~ Figure 3 Shown is an air-lift pulsating plug-flow three-dimensional circulation oxidation ditch 1 that adopts the strip-shaped funnel-type solid-liquid separator of Embodiment 1, including an anoxic zone 16 and an air-lift well that is provided with a microporous aerator group 4 Oxygen zone 14, aerobic zone 13, solid-liquid separation zone 12, raw water inlet pipe, drain pipe and mud discharge pipe, wherein, in the middle and lower part of the oxidation ditch 1, a channel is set to divide the oxidation ditch into upper and lower layers and A horizontal partition 7 with a distance between the front end and the front wall 18 of the oxidation ditch, and a distance between the rear end and the rear wall 15 of the oxidation ditch, the above-mentioned aerobic zone 13 is set in the upper channel, and the above-mentioned anoxic zone 16 is set in the lower channel; its characteristics The rear end of the above-mentioned horizontal partition 7 is connected to the incl...

Embodiment 2b

[0036] In this embodiment, the solid-liquid separator 2 of the air-lift pulsating plug-flow type three-dimensional circulation oxidation ditch is provided with 9 strip-shaped overflow tanks 28, 10 water-receiving weirs 27, and 5 parallel-connected strip-shaped funnels 25, The angle between the two shaped plates is 90°, and the distance between the bottom edges of the two shaped plates is 15cm. The angle between the inclined diversion wall 3 and the horizontal partition 7 is 120°; five vertical diversion wall sections 6 are arranged at the bottom of the horizontal partition 7 .

[0037] The amount of treated raw water (sewage) is 84m 3 / h, the total air supply volume is 2m 3 / min, the air supply volume of the continuous air supply microporous aerator group 41 is 1.6m 3 / min, the air supply volume of the intermittent air supply microporous aerator group 42 is 0.4m 3 / min, the microporous aerator group 42 is turned on for 7 minutes at intervals of 50 minutes.

[0038] This em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com