Optical power meter technology-based method for detecting interface bonding state of laser scratch

A technology of an optical power meter and a detection method, which is applied to measurement devices, instruments, mechanical devices, etc., can solve the problems such as the inability to establish the laser power and the strength of the film base, the inability to make accurate judgments on the critical position, and the failure and damage of the film base interface. To achieve the effect of intuitive display, reliable detection results, and easy observation and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] specific implementation plan

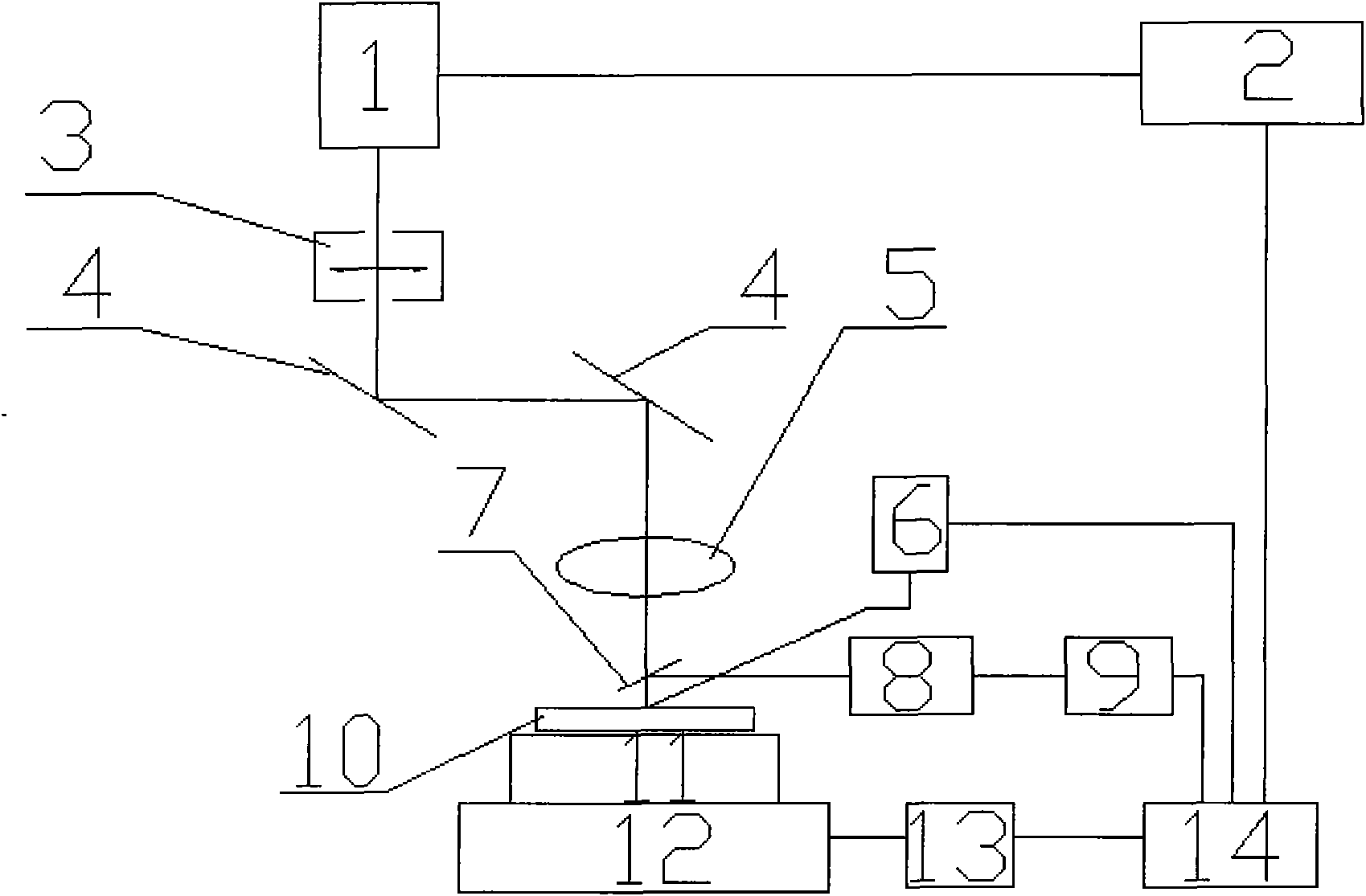

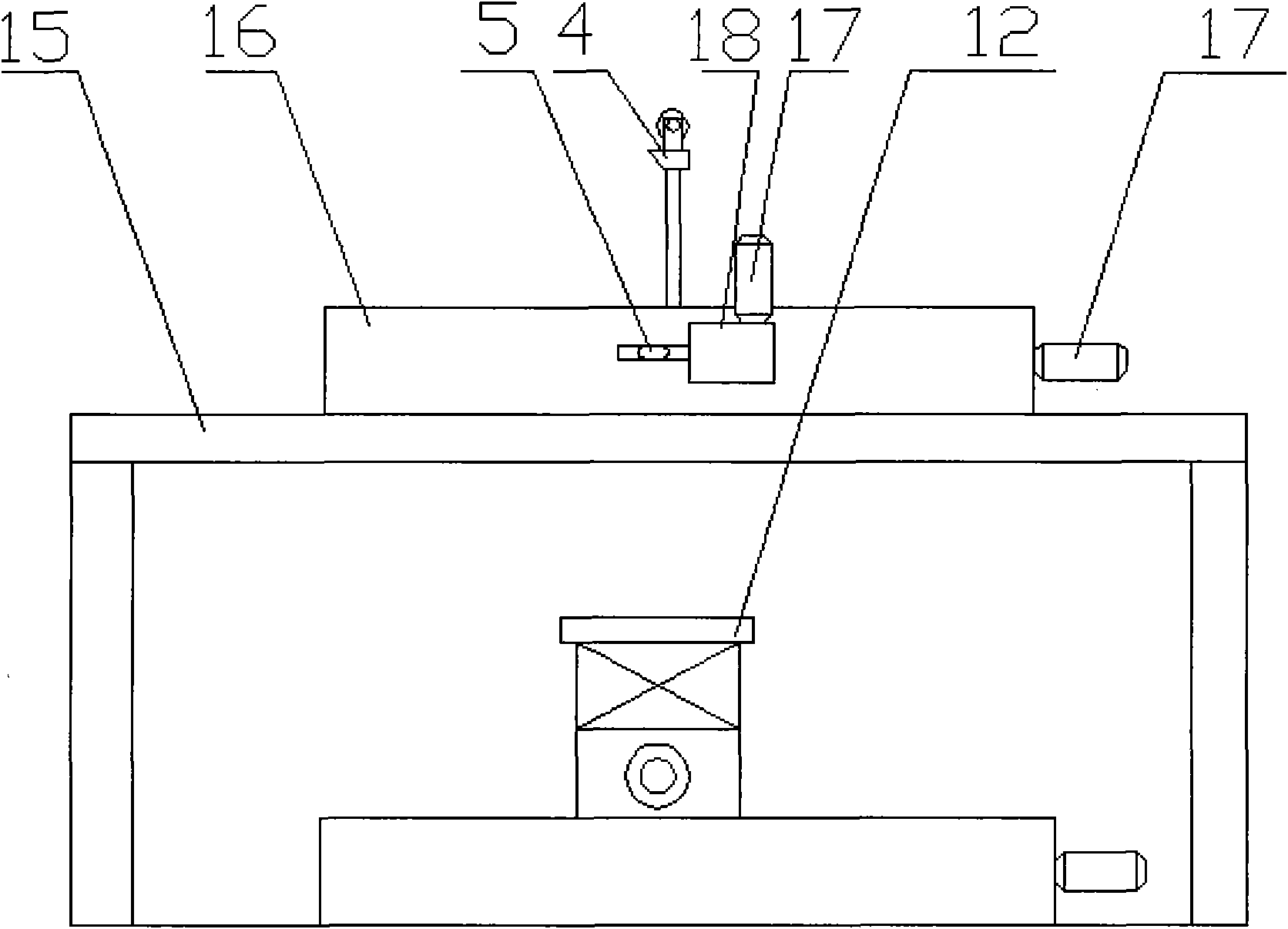

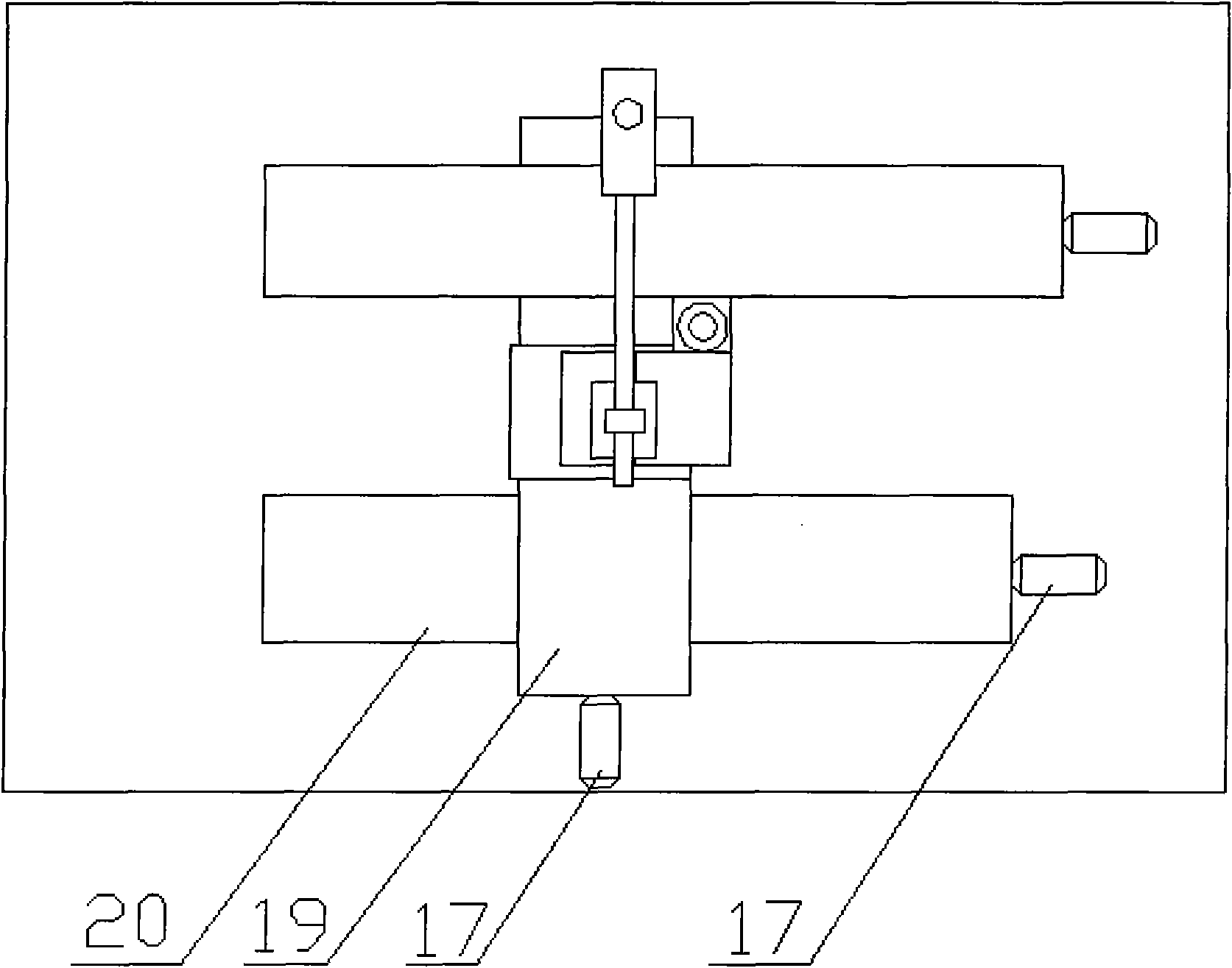

[0032] Depend on figure 1 Shown is a schematic diagram of the long-pulse infrared laser scratch and detection device, figure 2 and image 3It is the front view and top view of the workbench system. The semiconductor laser source 1 emits continuous infrared laser light which passes through the laser beam expander and collimation system 3 to make the laser beam in the direction of the slow axis of the laser more collimated, and then the laser beam passes through the mirror 4 to change the beam direction by 90 degrees. The light beam of 4 converges at one point after passing through the converging lens 5 fixed on the one-dimensional electronically controlled translation platform 18, and this point directly acts vertically on the support supported by the bracket 15 after passing through the mirror 4 fixed on the one-dimensional electronically controlled translation platform 16 On the two-dimensional electronically controlled translation p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com