Battery and manufacturing method thereof

A technology for batteries and battery cells, which is applied in secondary batteries, battery pack parts, final product manufacturing, etc. It can solve problems such as piercing by sharp substances, low mechanical strength, and potential safety hazards, and achieve simplified processing, low manufacturing costs, and good operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

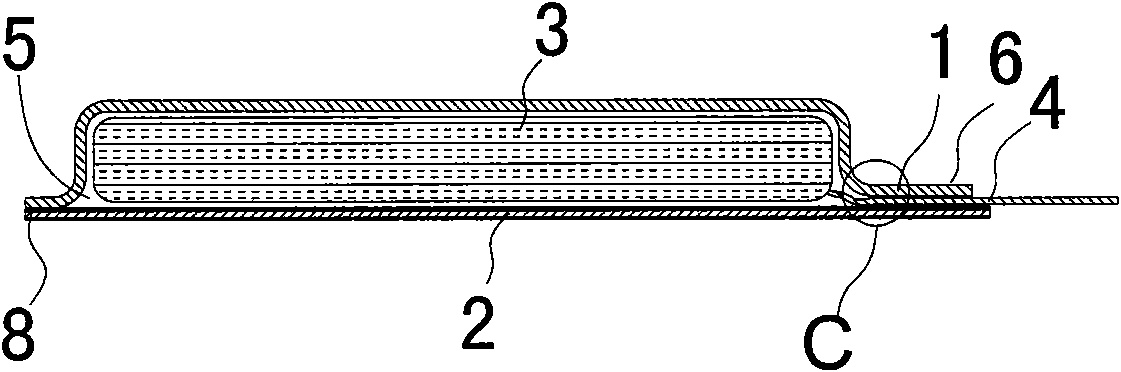

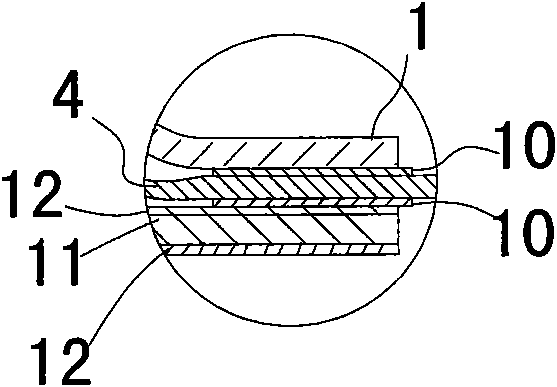

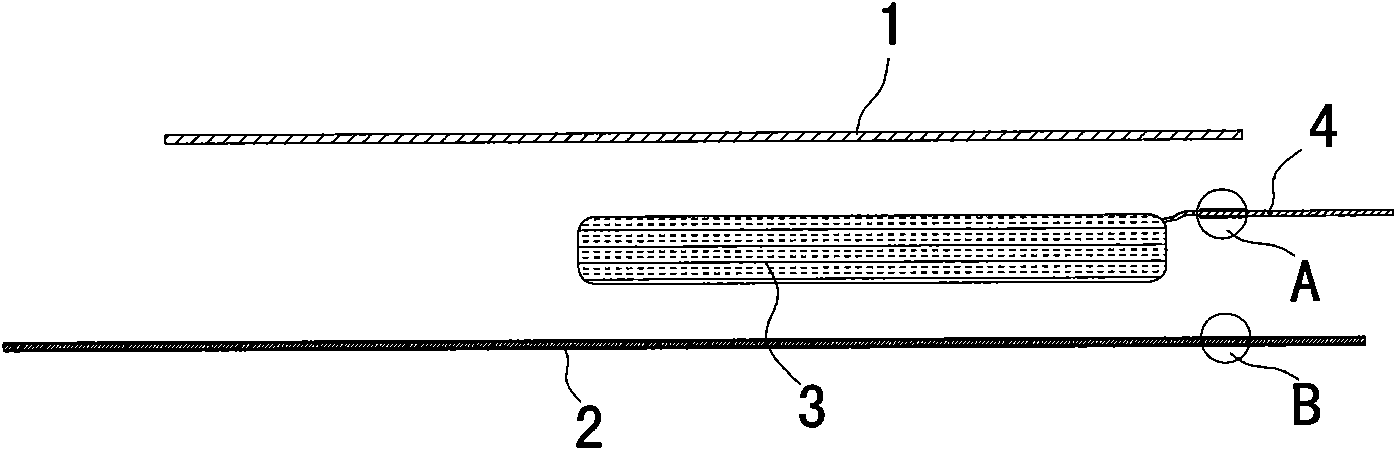

[0053] Step 101, such as image 3 , Figure 4 and Figure 5 As shown, a battery unit 3 with a positive terminal 4 and a negative terminal (set in parallel with the positive terminal, not shown) is prepared, and an aluminum plate with a thin plate structure of a certain size is cut as the substrate 1 and has a thin plate structure. The aluminum-plastic composite film (also called aluminum-plastic composite film) of the layered structure composite board of the structure is used as the layered structure composite board 2;

[0054] Step 102, such as Figure 6 , Figure 7 As shown, the substrate 1 is punched to form a cavity 5 and a peripheral edge 6 that can accommodate the battery unit 3, and then the laminated structure composite plate 2 is punched to form a second cavity 7;

[0055] Step 103, such as Figure 7As shown, the battery unit 3 is placed into the cavity 5, so that the positive terminal 4 and the negative terminal protrude from the peripheral edge 6; 4 and the ne...

Embodiment 2

[0063] Example 2: This example is basically the same as Example 1, except that the compounding temperature in step 103 is 120°C.

[0064] The processed battery was tested for shell connection peel strength, and the test results are shown in Table 5.

[0065] Sample No.

[0066] Sample No.

[0067] table 5

Embodiment 3

[0068] Example 3: This example is basically the same as Example 1, except that the compounding temperature in step 103 is 140°C. The processed battery was tested for shell connection peel strength, and the test results are shown in Table 6.

[0069] Sample No.

[0070] Table 6

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com