Trichosanthes kirilowii Maxim seed processing and storage method

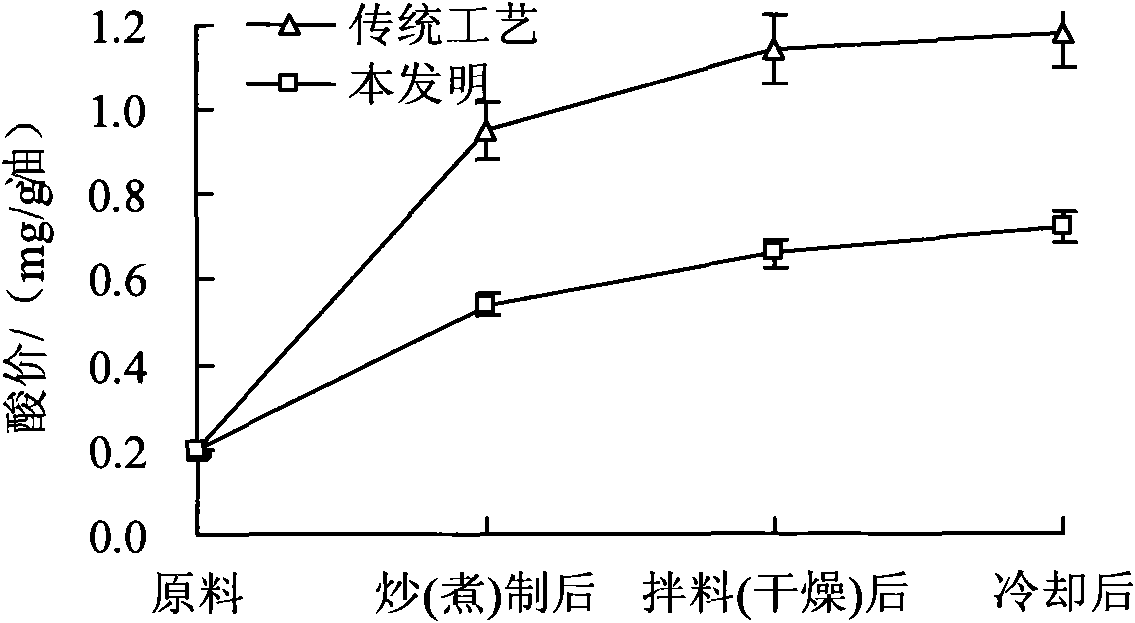

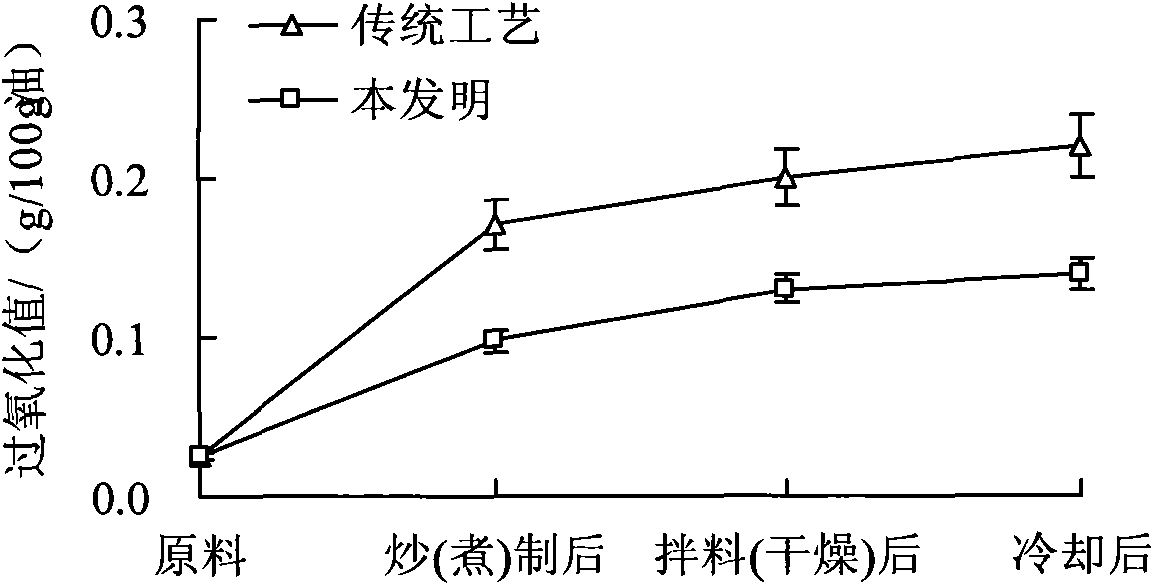

A technology of trichosanthes seeds and seasoning liquid, which is applied in the field of storage and processing of nuts and trichosanthes seeds, can solve the problems of rapid quality decline and short shelf life, and achieve the goal of reducing the degree of oxidation, prolonging the shelf life and inhibiting the rise of acid value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: (processing and storage method 1 of Trichosanthes chinensis seeds)

[0032] Proceed as follows:

[0033] (1) Selection of raw materials: remove impurities such as deflated seeds, small seeds, mildew, and moths, and select Trichosanthes seeds with full grains as raw materials for use;

[0034] (2) Preparation of seasoning liquid: Salt, spices, antioxidants and water are formulated into seasoning liquid in a ratio of 8% by weight: 1.4%: 0.3%: 90.3%, where the spices are ginger, fennel, star anise, pepper and cinnamon A mixture with a ratio of 2:1:5:1:1 by weight; the antioxidant in which is a mixture of TBHQ and BHT with a ratio of 1:1 by weight, for subsequent use;

[0035] (3) High-pressure cooking and seasoning: Put the raw materials of step (1) and the seasoning liquid of step (2) into the high-pressure equipment at a ratio of 0.8g: 1.0ml by weight and volume, heat to 121°C and cook for 30min at 0.2Mpa;

[0036] (4) Vacuum drying: pull out the boiled T...

Embodiment 2

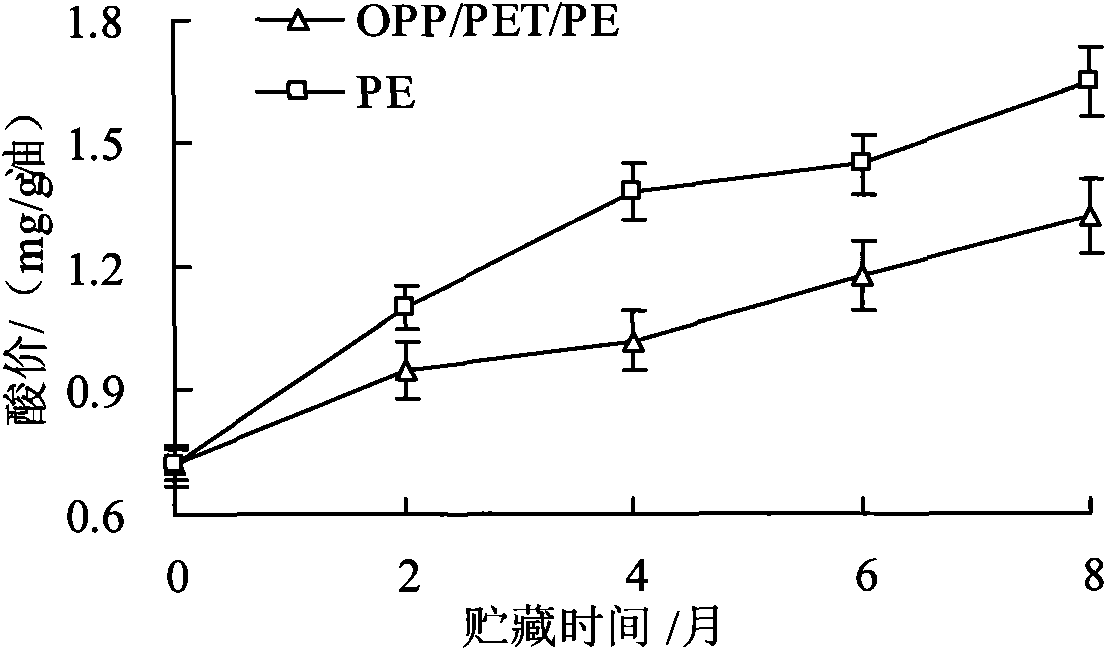

[0040] In this example, the preparation of step (2) seasoning liquid: the weight ratio of its salt, spices, antioxidants and water is 10%: 1.0%: 0.5%: 88.5%; step (3) high-pressure cooking and seasoning: its raw materials The weight-to-volume ratio with the seasoning liquid is 1.0g: 1.5ml; step (4) vacuum drying: the water content of the Trichosanthes seeds after drying is 4%; step (5) composite film vacuum packaging: the used OPP / PET / PE composite The film thickness is 100 μm, and the packaging bag is evacuated to 0.09Mpa; step (6) the storage temperature of the bagged product is 5° C., and the storage period is as long as 8 months; the remaining steps and processes are the same as in Example 1.

Embodiment 3

[0042] In this example, the preparation of step (2) seasoning liquid: the weight ratio of its salt, spices, antioxidants and water is 12%: 0.5%: 0.8%: 86.7%; step (3) high-pressure cooking and seasoning: its raw materials The weight-to-volume ratio with the seasoning liquid is 1.2g: 2.0ml; step (4) vacuum drying: the moisture content after the drying of its Trichosanthes seeds is 5%; step (5) composite film vacuum packaging: the used OPP / PET / PE composite The film thickness is 90 μm, and the inside of the packaging bag is evacuated to 0.08Mpa; step (6) the storage temperature of the bagged product is 15° C., and the storage period is as long as 7 months; the remaining steps and processes are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com