Integrated extrusion molding equipment

An extrusion molding and equipment technology, applied in the field of integrated extrusion molding equipment, can solve the problems affecting product output efficiency, product uniformity, accuracy and cleaning are difficult to guarantee, screw replacement process is difficult, etc., to facilitate replacement and repair. , the effect of improving utilization and avoiding security problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

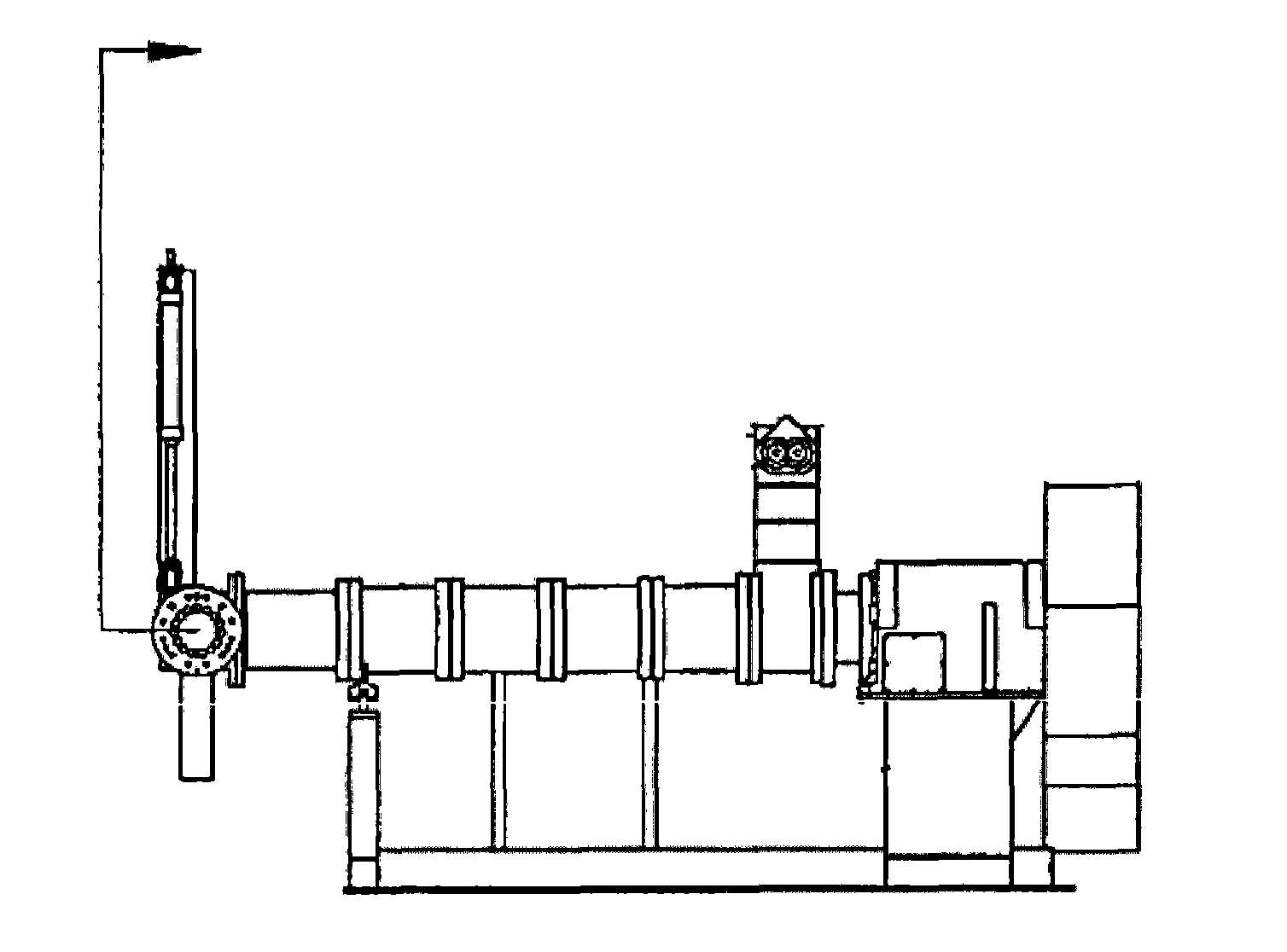

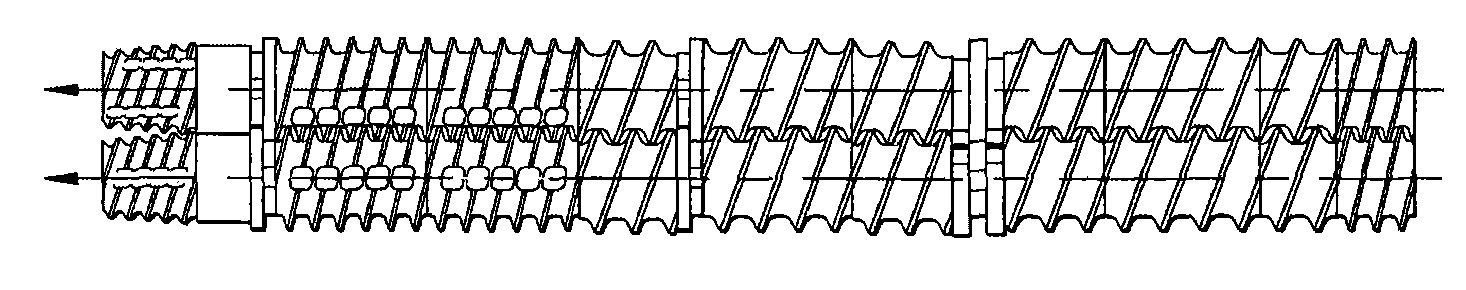

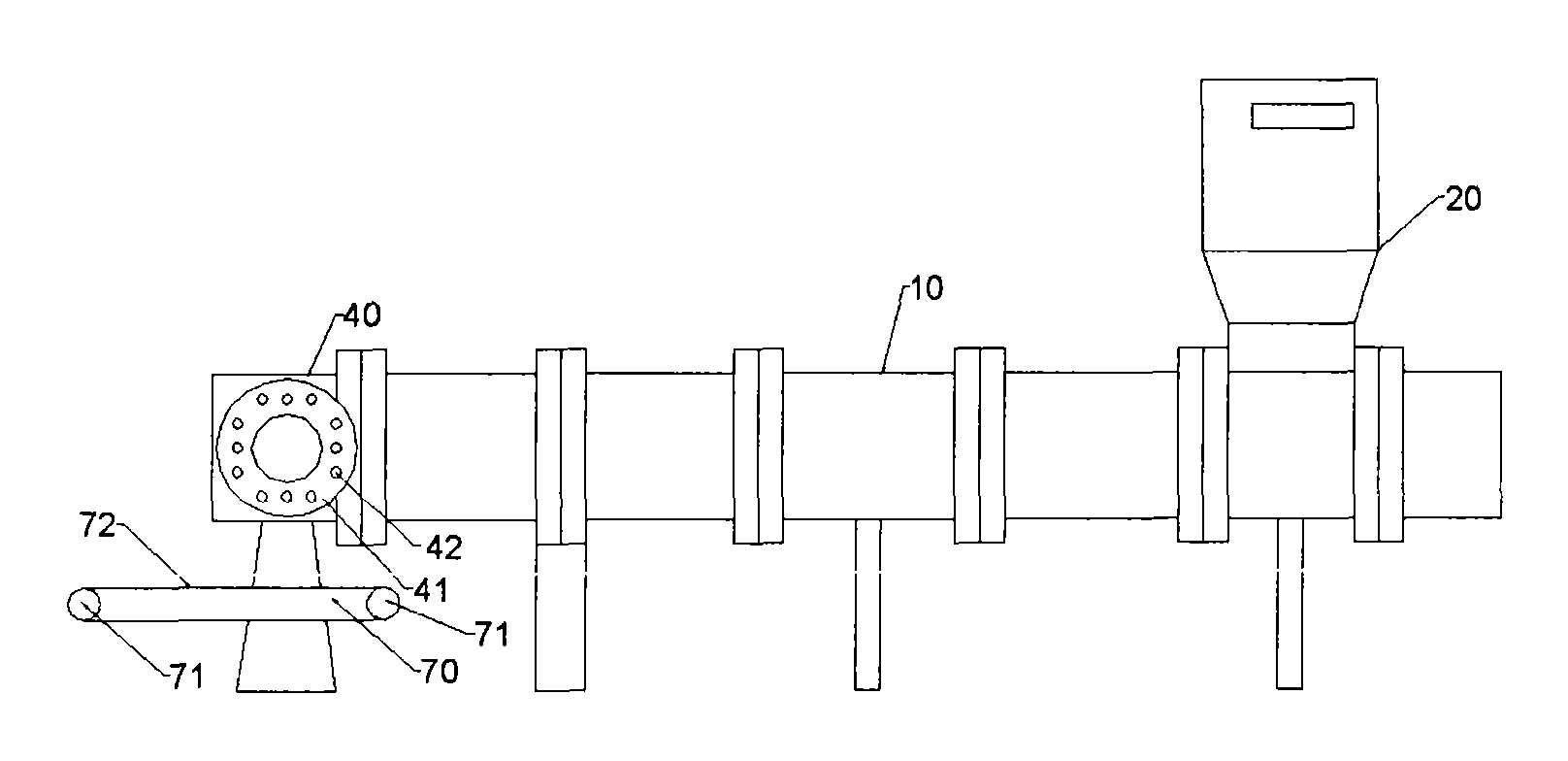

[0041] See attached image 3 and attached Figure 4 , is a horizontal flowchart of the extrusion molding equipment of the present invention and a top view of the equipment. Including a feeding device (20), a screw extruder (10), an extrusion die (40), a cutting device (30), a rotary motor box (50), wherein the feeding device (20) has a flow rate The feeding funnel of control valve and monitoring device; Described screw extruder (10) comprises the cavity that screw rod is installed, support strut, and a plurality of screw rods that mutually hermetically engage with cavity inside; Described extruding mold (40) There are two extrusion disks (41), the extrusion disks are in the shape of a truncated cone, and the extrusion ports are distributed on the outer ring surface of the disk. The material enters the screw extruder (10) through the feeding device (20). In the screw extruder, there is a twin-screw or multi-screw structure to carry out horizontal extrusion and conveying, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com