Special welding rod for -70 DEG C ferrite type low-temperature steel

A low-temperature steel and shape technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of unstable low temperature toughness of deposited metal, poor welding processability, low impact toughness of welded joints, etc. Stable, beautiful welding seam, small splash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

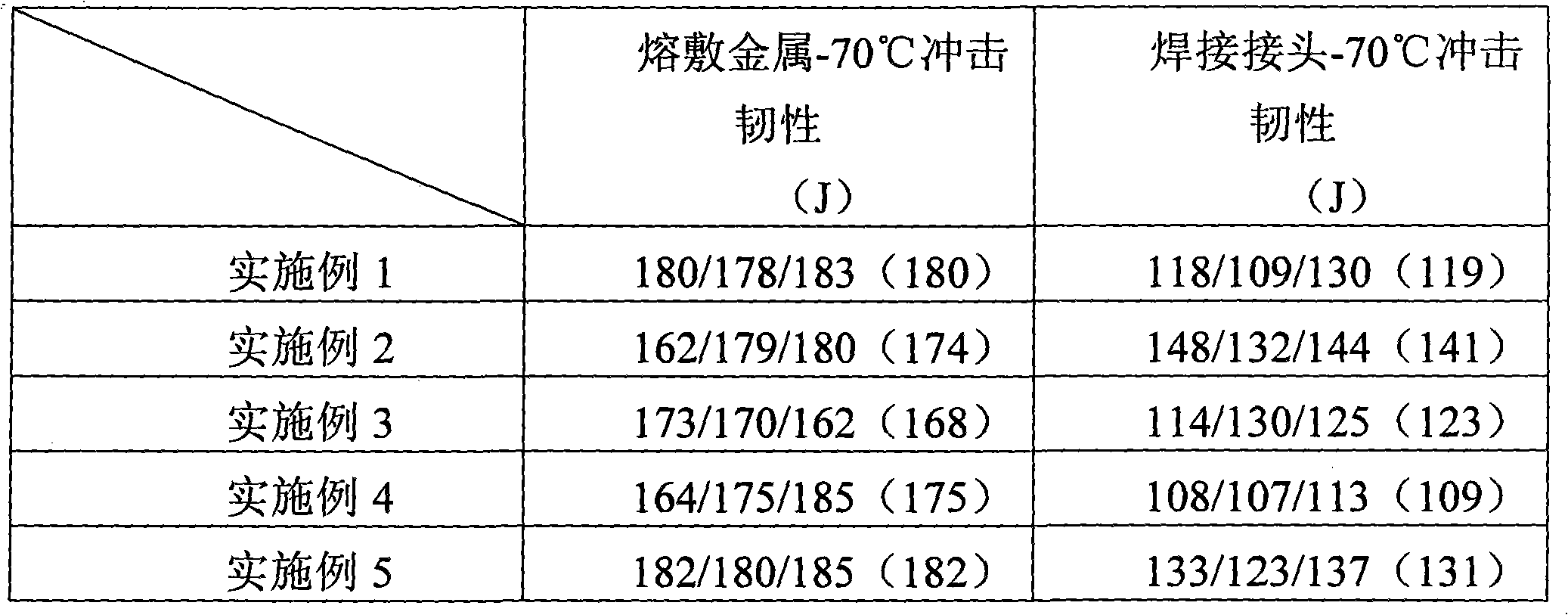

[0017] Embodiment 1, get 35 parts of marble; 29 parts of fluorite; 2 parts of titanium dioxide; 3 parts of quartz; 4 parts of mica; 6 parts of ferrosilicon; 2 parts of feldspar; 3 parts of iron sand, a total of 105kg of powder and mix evenly, add 26.50kg of potassium sodium water glass into the dry powder and mix evenly, apply it on the H08E low-alloy steel welding core with a hydraulic machine, and the electrode will naturally dry after 24 hours Leave to dry and then kiln-dried. Its welding process performance is good, especially it has excellent all-position welding processability. The V-notch impact toughness test values of its deposited metal and welded joints are shown in Table 2.

Embodiment 2

[0018] Example 2, get 38 parts of marble; 27 parts of fluorite; 1 part of titanium dioxide; 1 part of quartz; 3 parts of mica; 5 parts of ferrosilicon; 9 parts of ferrosilicon; 4 parts of feldspar; 4 parts of iron sand, a total of 104kg of powder and mix evenly, add 26.00kg of potassium sodium water glass into the dry powder and mix evenly, apply it on the H08E low alloy steel welding core with a hydraulic machine, and the electrode will naturally dry after 24 hours Leave to dry and then kiln-dried. Its welding process performance is good, especially it has excellent all-position welding processability. The V-notch impact toughness test values of its deposited metal and welded joints are shown in Table 2.

Embodiment 3

[0019] Embodiment 3, get 36 parts of marble; 28 parts of fluorite; 3 parts of titanium dioxide; 2 parts of quartz; 5 parts of mica; 4 parts of ferrosilicon; 3 parts of feldspar; 5 parts of iron sand, a total of 105kg of powder and mix evenly, add 26.50kg of potassium sodium water glass into the dry powder and mix evenly, press-coat it on the H08E low alloy steel welding core with a hydraulic machine, and the electrode will naturally dry after 24 hours Leave to dry and then kiln-dried. Its welding process performance is good, especially it has excellent all-position welding processability. The V-notch impact toughness test values of its deposited metal and welded joints are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com