Single-sided welding double-sided forming welding wire without argon protection on the back

A single-sided welding double-sided, argon-free technology, used in welding media, welding equipment, welding/cutting media/materials, etc., to achieve excellent slag removal performance, excellent all-position welding manufacturability, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

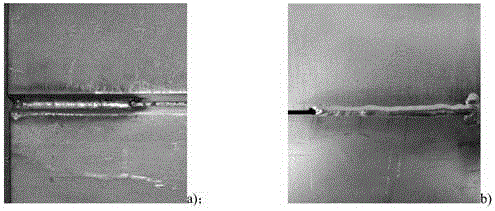

Embodiment 1

[0045] Example 1: Preparation of welding wire for single-sided welding and double-sided forming without argon protection on the back

[0046] (a) In parts by weight, take 40 parts of marble, 5 parts of fluorite, 5 parts of titanium dioxide, 1 part of quartz, 6 parts of ferrosilicon, 1 part of ferrotitanium, 4 parts of electrolytic manganese, 2 parts of rutile, and 10 parts of metallic chromium The powder is mixed evenly;

[0047] (b) Based on 100 parts by weight of the mixed powder in step (a), add 25 parts by weight of potassium sodium water glass to the dry powder and mix it evenly, and apply it on the core ERNiCr-3 nickel-based welding wire with a hydraulic press. After 12 hours of natural drying, and drying at high temperature, a welding wire with single-sided welding, double-sided forming, and argon-free protection on the back is obtained.

[0048] The welding wire obtained in this embodiment is used to weld the corresponding base metal, and the process parameters are:...

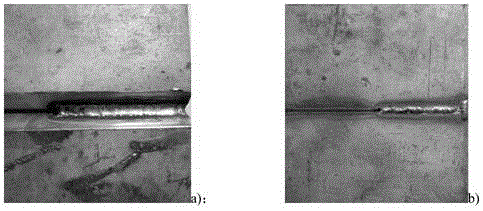

Embodiment 2

[0049] Example 2: Preparation of welding wire for single-sided welding and double-sided forming without argon protection on the back

[0050] (a) In parts by weight, take 20 parts of marble, 19 parts of fluorite, 1 part of titanium dioxide, 5 parts of quartz, 2 parts of ferrosilicon, 6 parts of ferrotitanium, 1 part of electrolytic manganese, 30 parts of rutile, and 3 parts of metallic chromium The powder is mixed evenly;

[0051] (b) Based on the mixed powder of step (a) per 100 parts by weight, add 20 parts by weight of potassium sodium water glass into the dry powder and mix evenly, and apply it on the welding core ER308L stainless steel wire with a hydraulic press. After drying and drying at high temperature, a welding wire with single-sided welding, double-sided forming, and argon-free protection on the back is obtained.

[0052] The welding wire obtained in this embodiment is used to weld the corresponding base metal, and the process parameters are: welding current of...

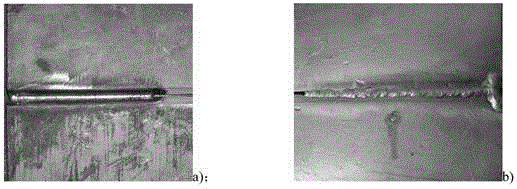

Embodiment 3

[0054] Example 3: Preparation of welding wire for single-sided welding and double-sided forming without argon protection on the back

[0055] (a) In parts by weight, take 40 parts of marble, 15 parts of fluorite, 5 parts of titanium dioxide, 4 parts of quartz, 4 parts of ferrosilicon, 5 parts of ferrotitanium, 3 parts of electrolytic manganese, 15 parts of rutile, and 5 parts of metallic chromium The powder is mixed evenly;

[0056](b) Based on 100 parts by weight of the mixed powder in step (a), add 30 parts by weight of potassium sodium water glass to the dry powder and mix evenly, and apply it to the core ERNiCrMo-3 nickel-based welding wire with a hydraulic press. After 12 hours of natural drying, and drying at high temperature, a welding wire with single-sided welding, double-sided forming, and argon-free protection on the back is obtained.

[0057] The welding wire obtained in this embodiment is used to weld the corresponding base metal, and the process parameters are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com