Active scarlet dye composition

A technology of dye composition and reactive scarlet, which is applied in organic dyes, dyeing methods, textiles and papermaking, etc. It can solve the problems of poor lifting power, washing resistance, chlorine resistance, friction resistance and perspiration resistance, and the fastness to wet treatment does not meet the requirements. , to achieve the effect of close lifting performance, outstanding staining fastness performance and close color fixation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

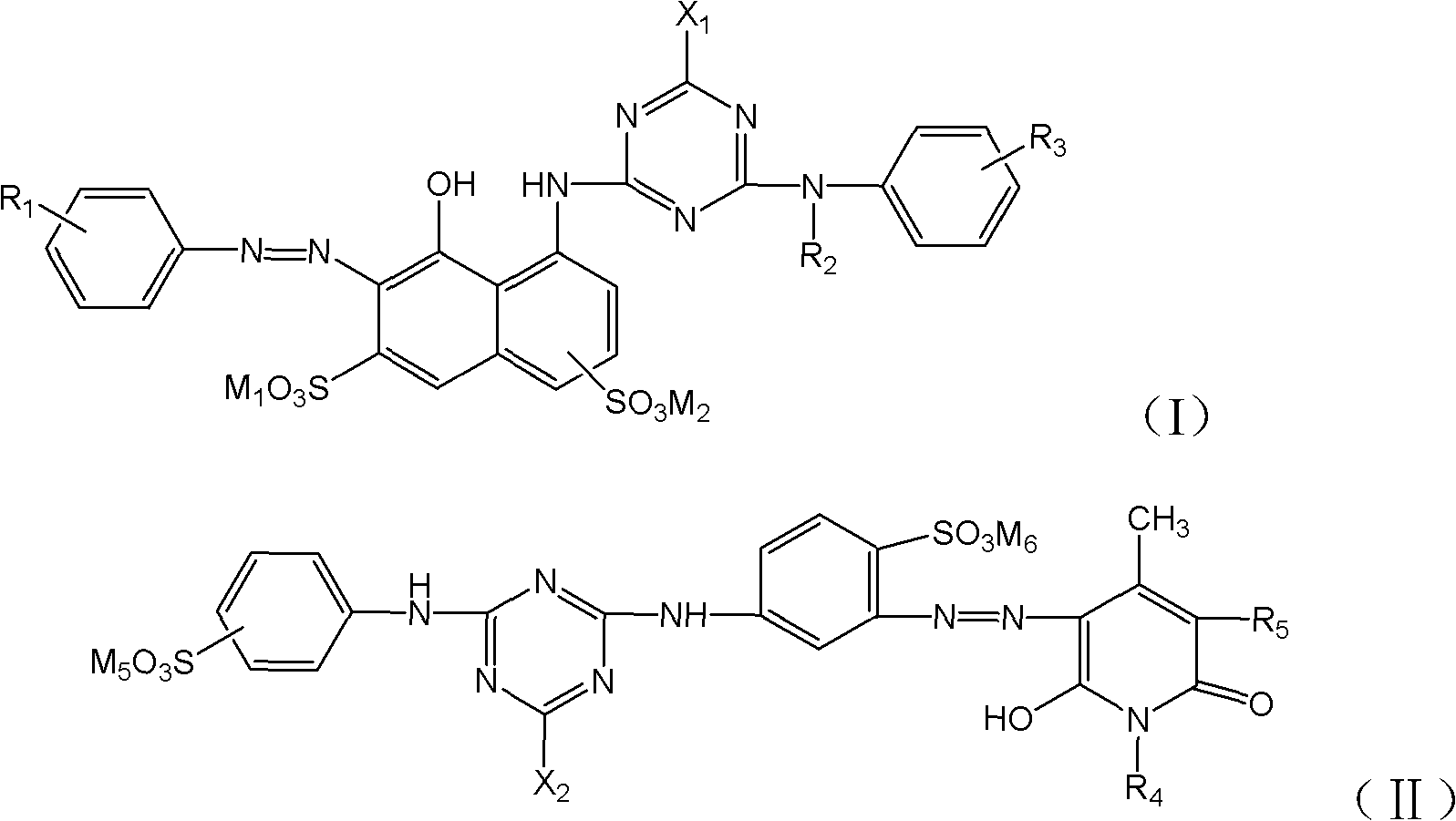

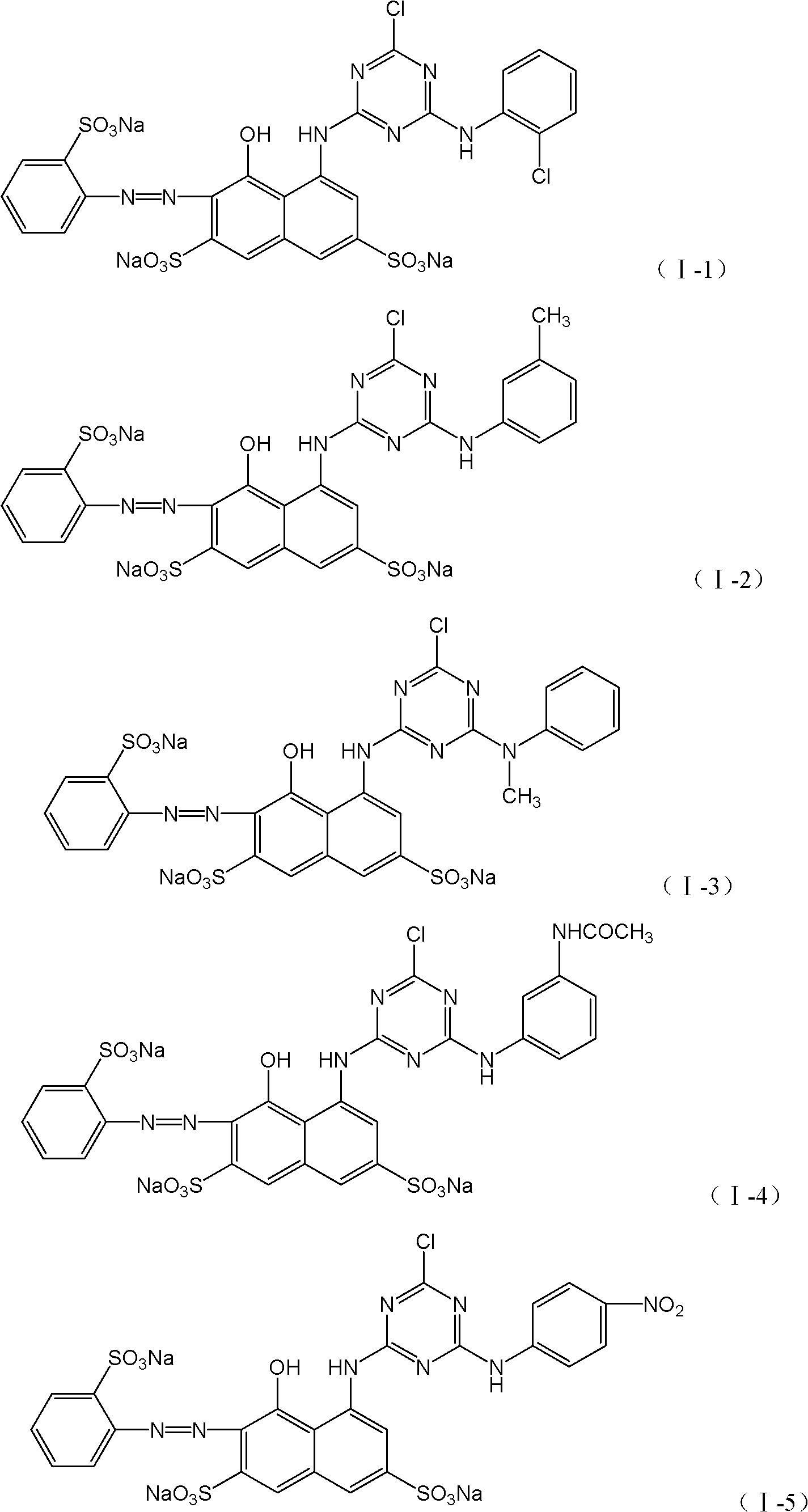

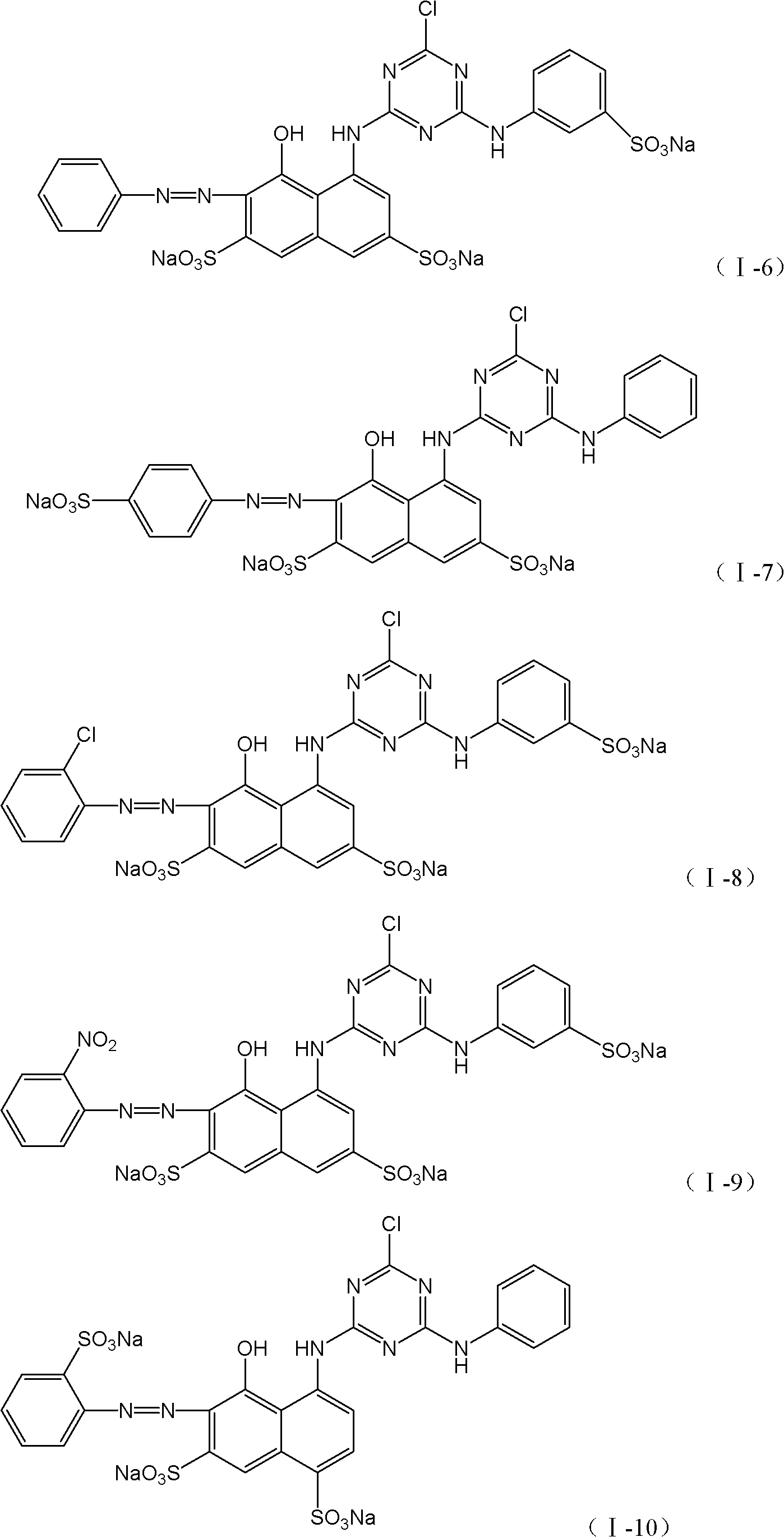

Method used

Image

Examples

Embodiment 1

[0032] Component A shown in 70 grams of formula (I-1), component B shown in 30 grams of formula (II-1), 10 grams of sodium sulfate, 5 grams of sodium lignosulfonate are mixed in a mixing tank , or co-dissolved and then dried to obtain the reactive dyes of the present invention, which can provide bright red hues with excellent fastness properties to fabrics.

[0033]

Embodiment 2~13

[0035] According to the method described in Example 1, the difference is that the structure and weight ratio of component A and component B in Table 1 are adopted. In addition, the addition of sodium bicarbonate is 25 grams, and mixing is carried out, and this product can also be obtained. The reactive dye described in the invention can provide bright red hues with excellent fastness properties to fabrics.

[0036] Table 1

[0037] Example

Embodiment 14

[0038] Example 14: Dyeing

[0039] At 60° C., 100 grams of cotton fabric were added to the dyebath containing 1500 grams of 45 g / L sodium chloride and 2 grams of the reactive dyes obtained according to Examples 1-13. After dyeing at this temperature for 45 minutes, add 20g / L sodium carbonate solution and keep this temperature for another 45 minutes. Then, rinse the stain, soap with a non-ionic detergent for 15 minutes, rinse and dry. According to the methods determined in ISO 105-B02, ISO105-CO3, ISO 105×12 and ISO 105-E04, the color fastness to sunlight ≥ grade 5-6, the color fastness to washing ≥ grade 4-5, Color fastness to rubbing (wet rubbing) ≥ 4 grades, color fastness to perspiration ≥ 4 to 5 grades.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com