Method for extracting rice bran oil by using ionic liquid and supercritical carbon dioxide (CO2)

An ionic liquid and supercritical technology, which is applied in the direction of fat oil/fat production and fat generation, can solve the problems of reducing the efficiency of the extraction process, and achieve the effect of simple process flow, small equipment footprint, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

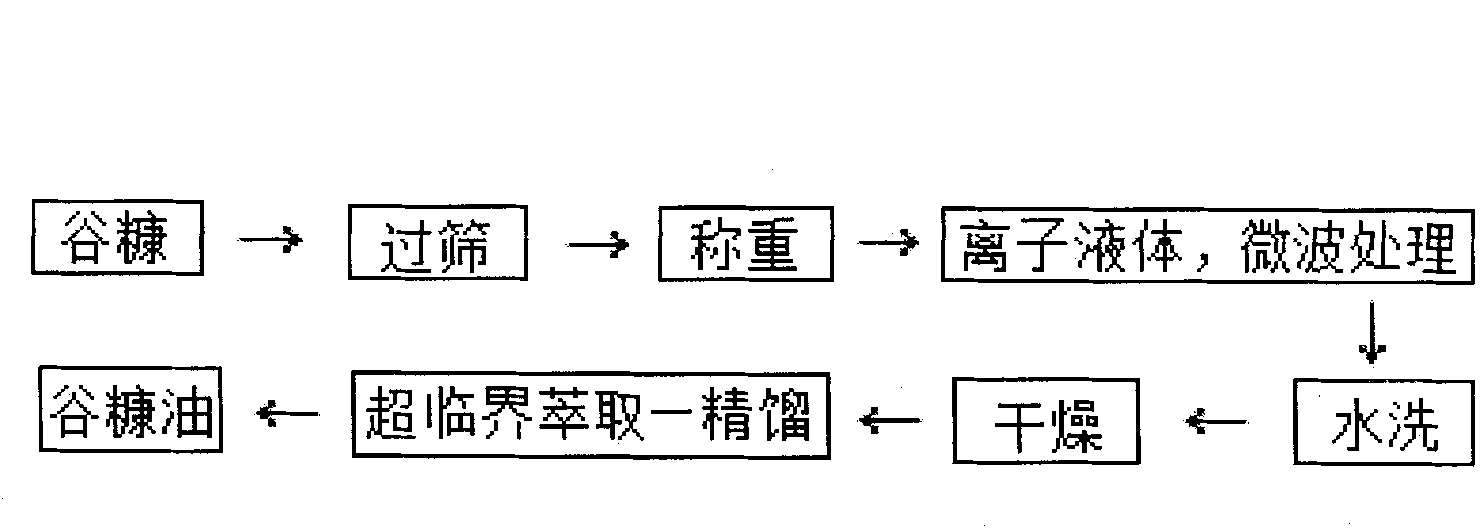

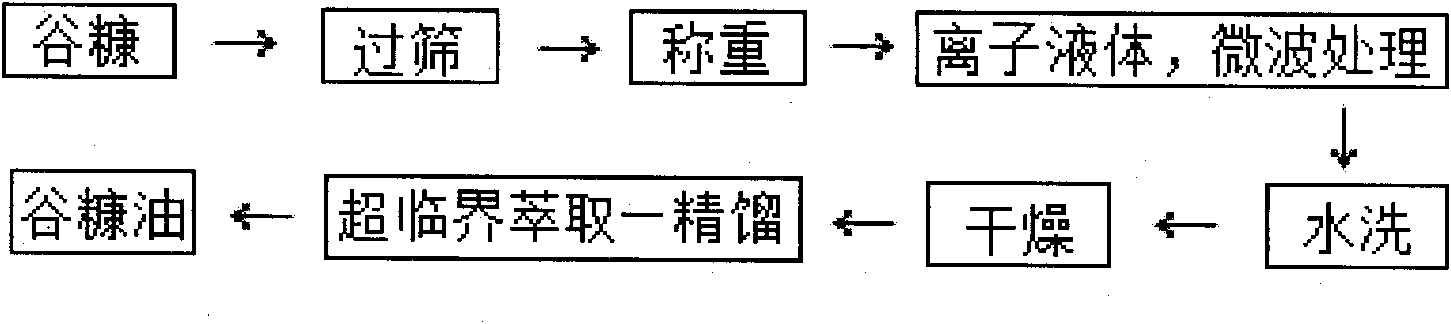

[0025] An ionic liquid-supercritical CO 2 The method for extracting rice bran oil, the steps are:

[0026] A. Take 300g of rice bran with a particle size of 40 mesh, add 60-90ml of ionic liquid BmimC1 under the condition of 800W power microwave heating, soak for 120s, wash twice with water, recover the ionic liquid, and dry the rice bran;

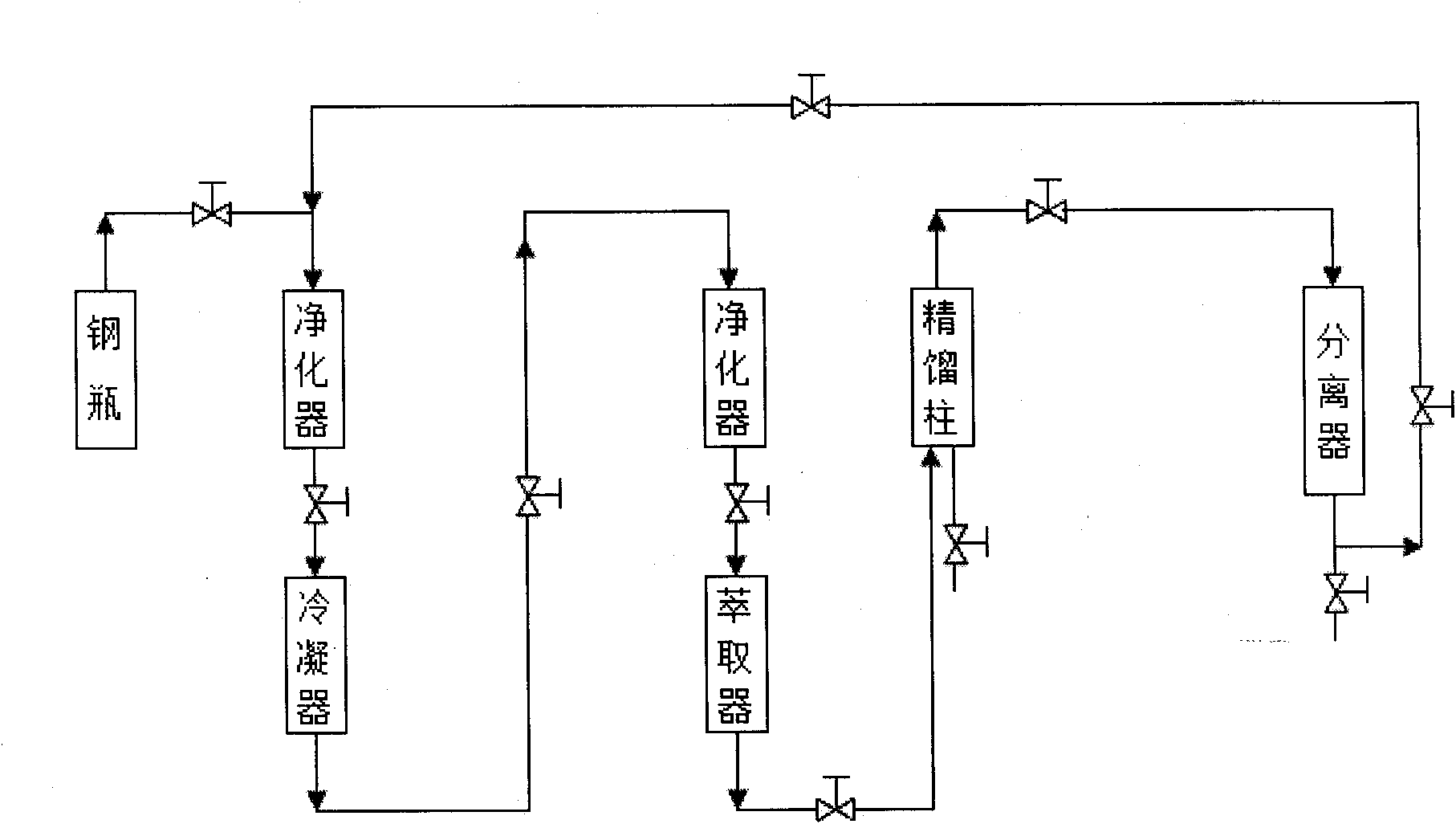

[0027] B. Put the rice bran obtained in the previous step into supercritical CO 2 In the extractor of the fluid extraction-rectification integrated equipment, tighten the pressure ring seal and open the CO 2 Steel cylinder, the gas is purified by the purifier and enters the condenser for liquefaction, then pressurized by the plunger pump and purified by the purifier for the second time, and then enters the bottom of the extractor through the pipeline, the extraction temperature is controlled at 39-55°C, and the extraction pressure is 20-35Mpa , CO 2 The fluid enters the material layer in the charging cylinder through the metal distributi...

Embodiment 2

[0029] An ionic liquid-supercritical CO 2 The method for extracting rice bran oil, the steps are:

[0030] A. Take 300g of rice bran with a particle size of 40 mesh, add 60ml of ionic liquid BmimC1 under the condition of 800W power microwave heating, soak for 120s, wash twice with water, recover the ionic liquid, and dry the rice bran;

[0031] B. Put the rice bran obtained in the previous step into supercritical CO 2 In the extractor of the fluid extraction-rectification integrated equipment, tighten the pressure ring seal and open the CO 2 Steel cylinder, the gas is purified by the purifier and enters the condenser for liquefaction, then pressurized by the plunger pump and purified by the purifier for the second time, and then enters the bottom of the extractor through the pipeline, the extraction temperature is controlled at 45°C, the extraction pressure is 30Mpa, C0 2The fluid enters the material layer in the charging cylinder through the metal distribution plate for ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com