Aluminum-magnetism aluminum alloy for automobile body plate of automobile and manufacturing method thereof

A technology of an automobile body panel and a manufacturing method, which are applied in the field of aluminum-magnesium series aluminum alloy for automobile body panel and its manufacture, aluminum alloy and its manufacture, can solve the problem that the strength and dent resistance cannot meet the requirements of the body panel and affect the surface Quality, impact resistance and other problems, to achieve good economic benefits, improve corrosion resistance, strength and tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

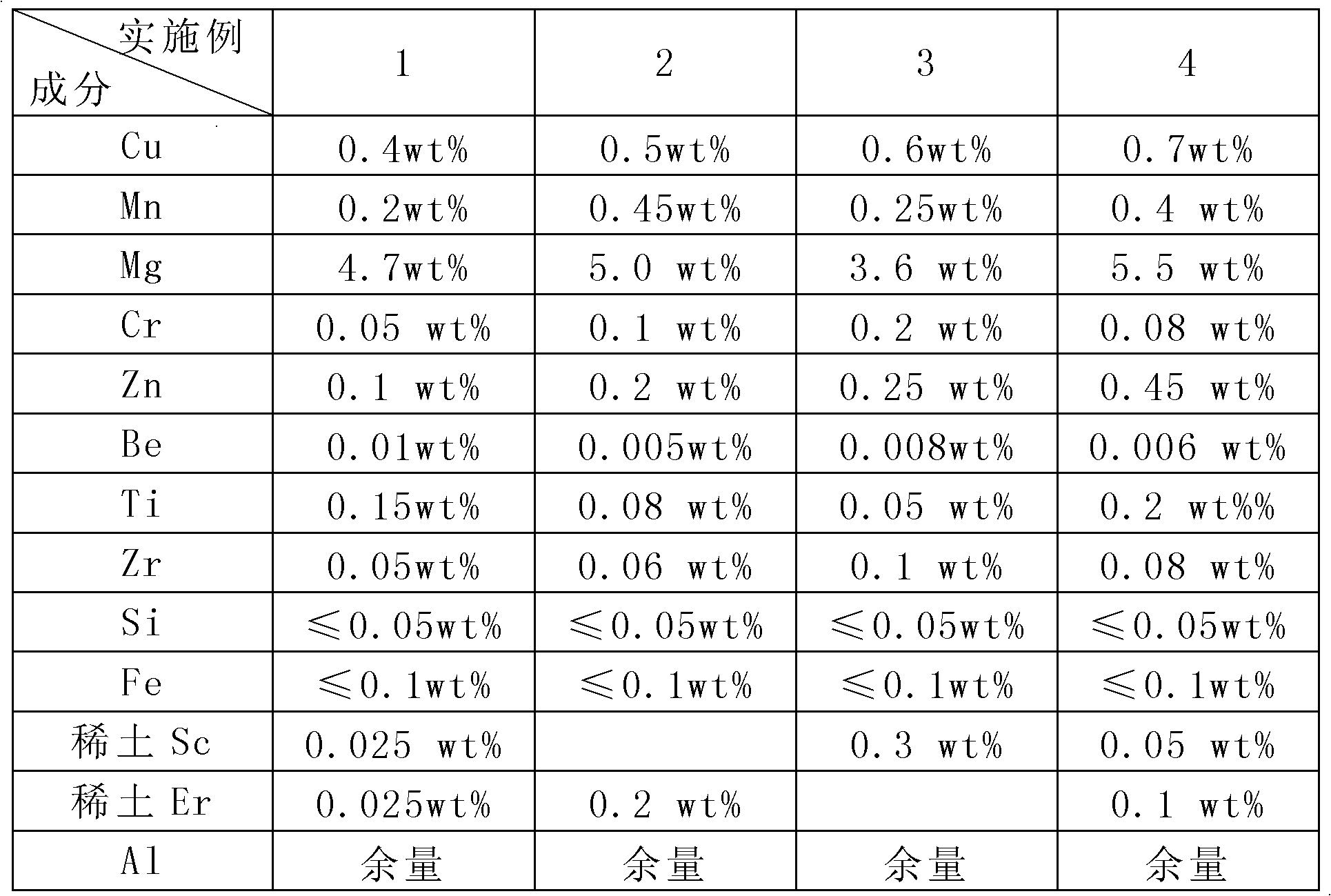

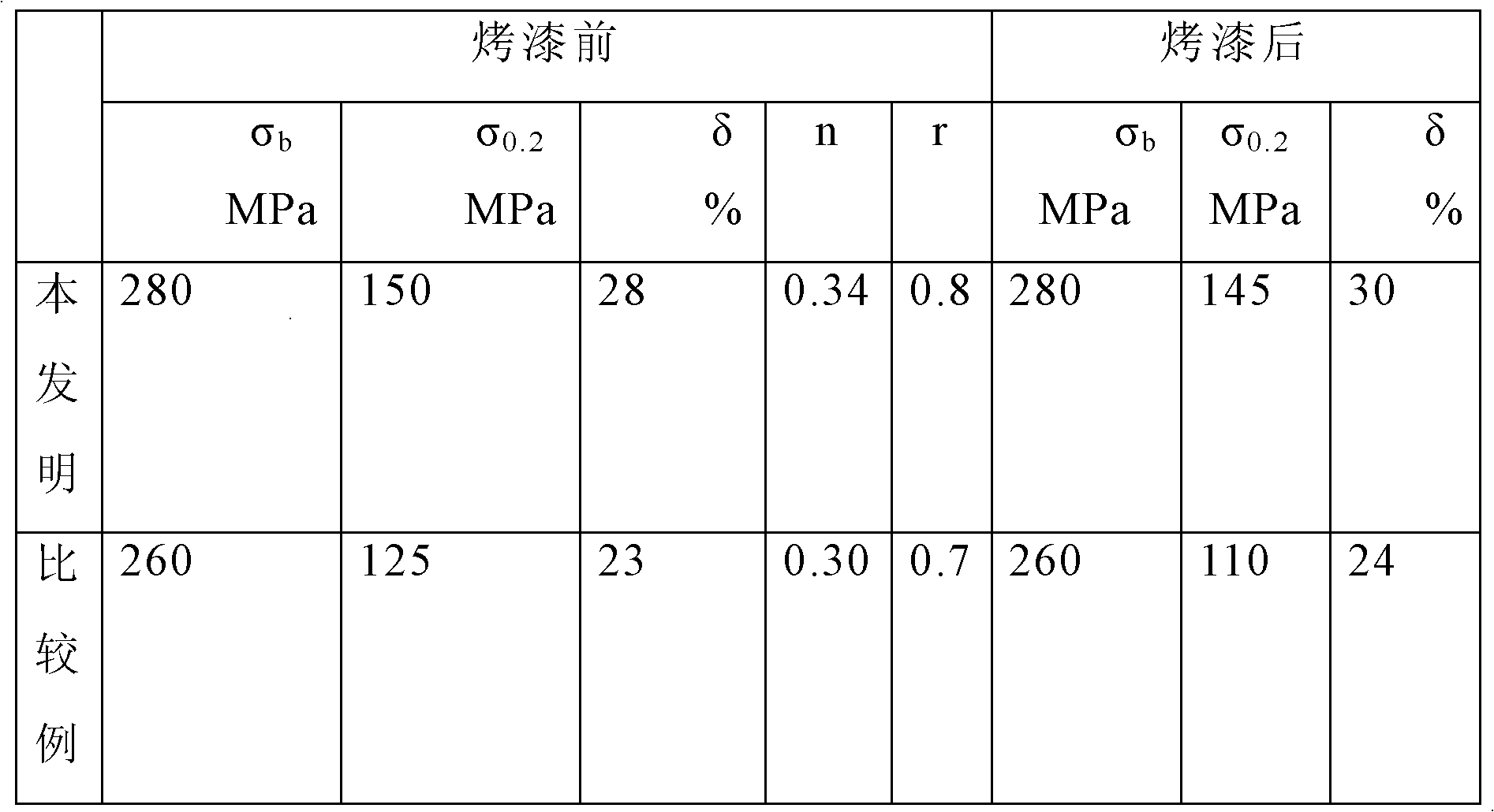

Examples

Embodiment 1

[0044] The batching was carried out according to the mass percentage of Example 1 in Table 1 to make aluminum ingots, master alloys AlCu50, AlMn10, AlCr4, AlBe3, AlZr4, Al-5Ti-B and Al-rare earth.

[0045] First put the aluminum ingot into the crucible resistance furnace, when the aluminum ingot is melted and the melt temperature is 740°C, add AlCu50, AlMn10, AlCr4, AlBe3, AlZr4 intermediate alloys and stir; when the melt temperature drops to 710°C, add Mg and Zn, slagging and refining; when the temperature is 710°C, add Al-rare earth, Al-5Ti-B master alloy, stir and stand for 15 minutes, and cast in a cast iron mold at a temperature of 720°C;

[0046] Homogenize the aluminum alloy ingots formed by casting above, the temperature of the homogenization treatment is 400°C, and the treatment time is 24 hours; hot rolling at a temperature of 400°C, intermediate annealing for 40 minutes, and cold rolling twice to form a thin plate;

[0047] The thin plate prepared above is subjected...

Embodiment 2

[0049] According to the mass percentage of Example 2 in Table 1, the ingredients were prepared to make aluminum ingots, master alloys AlCu50, AlMn10, AlCr4, AlBe3, AlZr4, Al-5Ti-B and Al-rare earth.

[0050] First put the aluminum ingot into the crucible resistance furnace, when the aluminum ingot is melted and the melt temperature is 750°C, add AlCu50, AlMn10, AlCr4, AlBe3, AlZr4 intermediate alloys and stir; when the melt temperature drops to 720°C, add Mg and Zn, slag removal and refining; when the temperature is 720°C, add Al-rare earth and Al-5Ti-B master alloy, stir and stand for 12 minutes, and pour into a cast iron mold at a temperature of 720°C;

[0051] Homogenize the casted aluminum alloy ingot above, the homogenization temperature is 420°C, and the processing time is 18 hours; hot rolling at 420°C, intermediate annealing for 30 minutes, cold rolling twice to form a thin plate;

[0052] The thin plate prepared above is subjected to solution treatment, the temperatur...

Embodiment 3

[0054] The batching was carried out according to the mass percentage of Example 3 in Table 1 to make aluminum ingots, master alloys AlCu50, AlMn10, AlCr4, AlBe3, AlZr4, Al-5Ti-B and Al-rare earth.

[0055] First put the aluminum ingot into the crucible resistance furnace, when the aluminum ingot melts and the melt temperature is 760°C, add AlCu50, AlMn10, AlCr4, AlBe3, AlZr4 intermediate alloys and stir; when the melt temperature drops to 730°C, add Mg and Zn, slag removal and refining; when the temperature is 730°C, add Al-rare earth and Al-5Ti-B master alloy, stir and stand for 12 minutes, and pour into a cast iron mold at a temperature of 730°C;

[0056] Homogenize the aluminum alloy ingots formed by casting above. The temperature of the homogenization treatment is 440°C, and the treatment time is 15 hours; hot rolling at a temperature of 440°C, intermediate annealing for 25 minutes, and cold rolling twice to form a thin plate;

[0057] The thin plate prepared above is subj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com