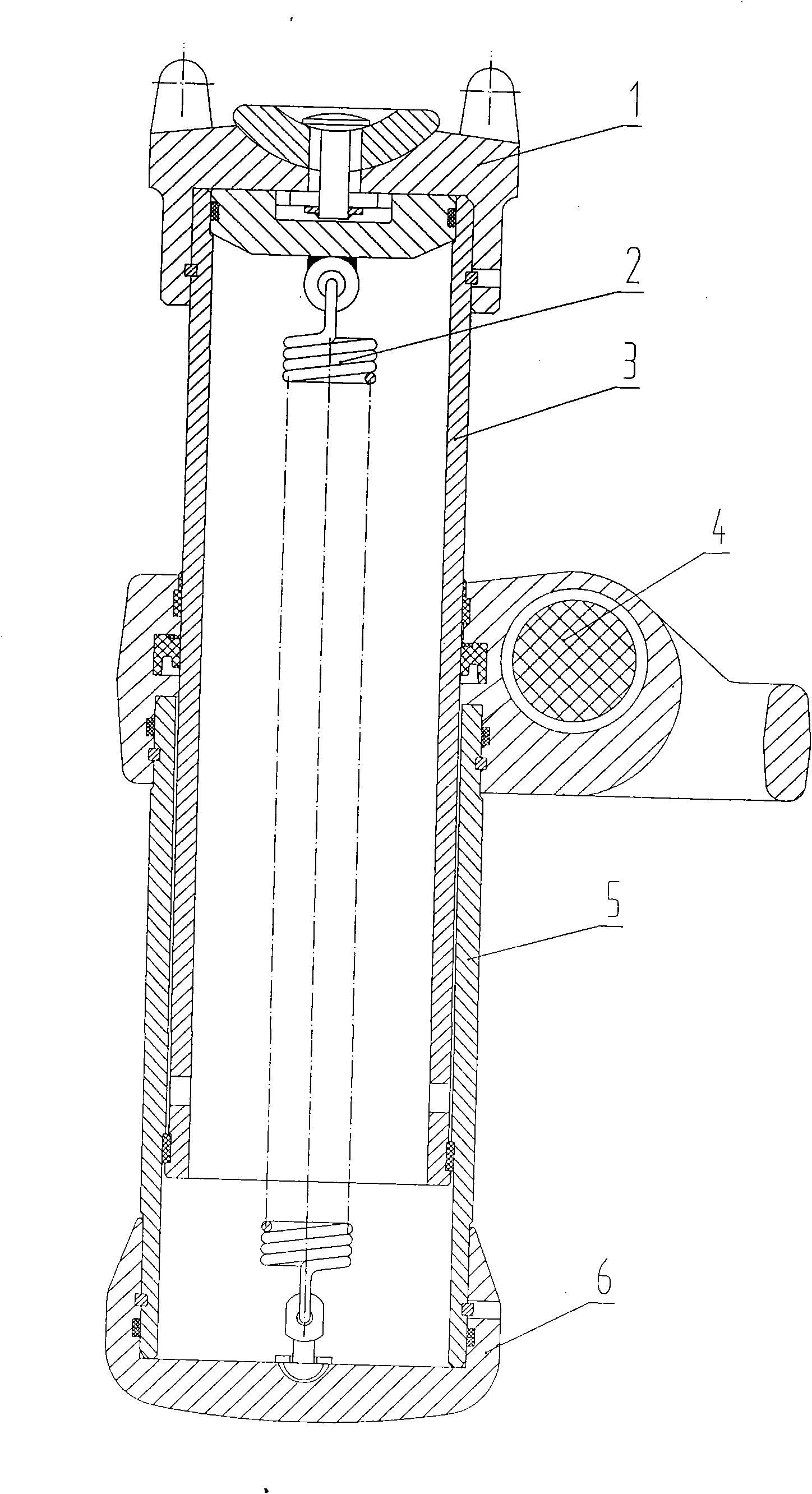

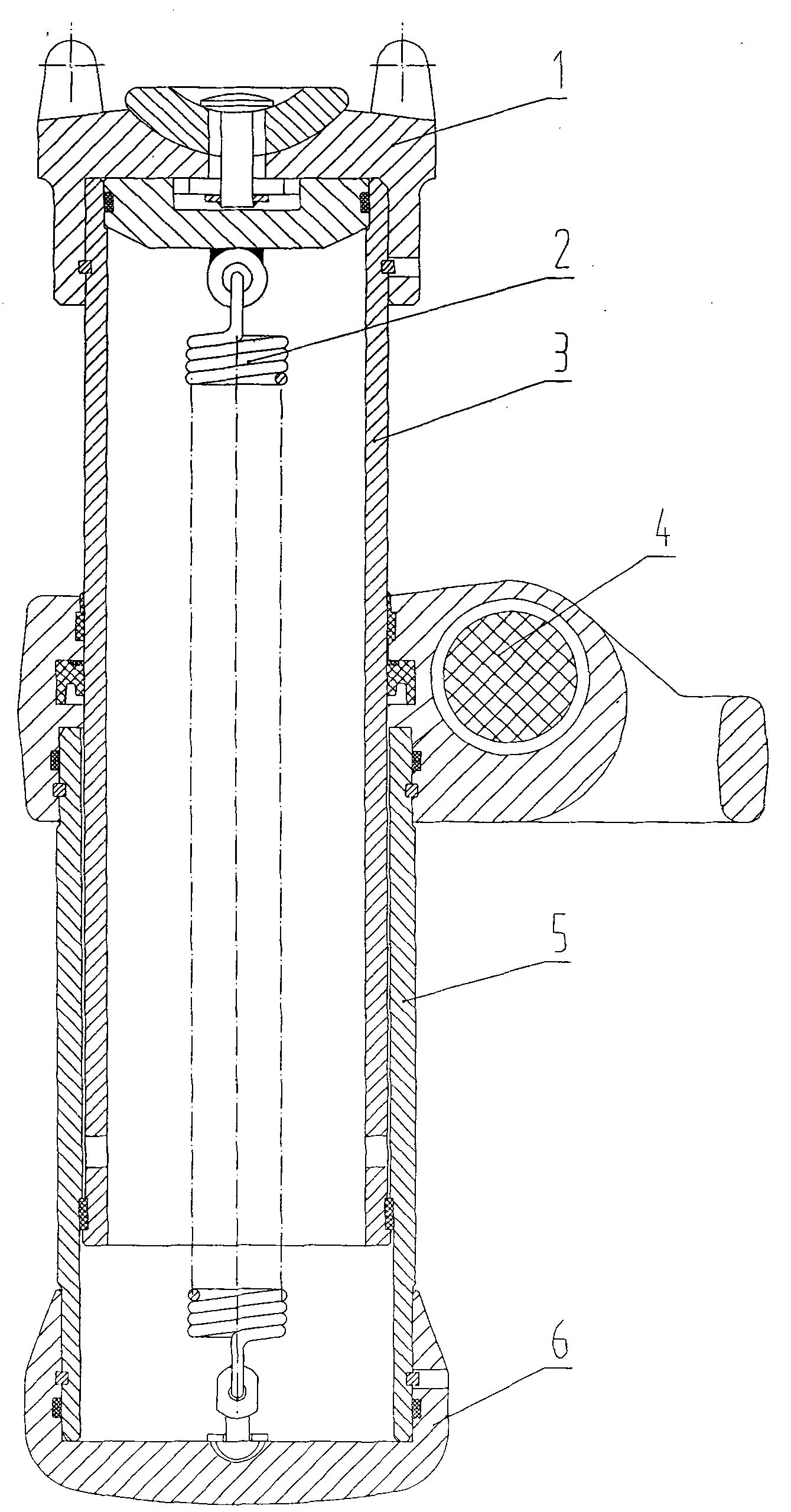

Mining single hydraulic prop manufactured by using welded steel pipes

A technology of single hydraulic prop and welded steel pipe, which is applied in the direction of prop/support, mining equipment, earthwork drilling and mining, etc. It can solve problems such as cracks, poor toughness of steel pipes, and large cutting allowance, so as to reduce manufacturing costs and prolong service life , The effect of small cutting allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] As shown in the accompanying drawings, the cylinder body 5 and the active column 3 of the mine-used single hydraulic prop are made of high-frequency welded pipes. Welded pipe shaping and heat treatment methods have more stringent requirements, and the process is as follows:

[0014] 1. The welded pipe blank strip steel is continuously formed into a tubular shape.

[0015] 2. Heat both sides of the seam to a certain temperature, and weld under pressure.

[0016] 3. Remove the inner and outer wall burrs.

[0017] 4. Use the intermediate frequency induction heating device to heat the weld area to the temperature of the austenitic body; keep it warm for a certain period of time; carry out air cooling to below 400-500°C; carry out water cooling to eliminate the internal stress at the weld.

[0018] 5. The welded pipe is shaped by a sizing machine to meet the requirements of diameter tolerance and out-of-roundness tolerance.

[0019] 6. Cut to length according to the heigh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap