Embedded electromagnetic-elastic foil gas mixing bearing

An elastic foil, gas mixing technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of easy peeling of the coating on the bearing, uncontrollable gas bearings, low damping and stiffness, etc., to improve the coaxiality. Compatibility, overall volume reduction, high dynamic stiffness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

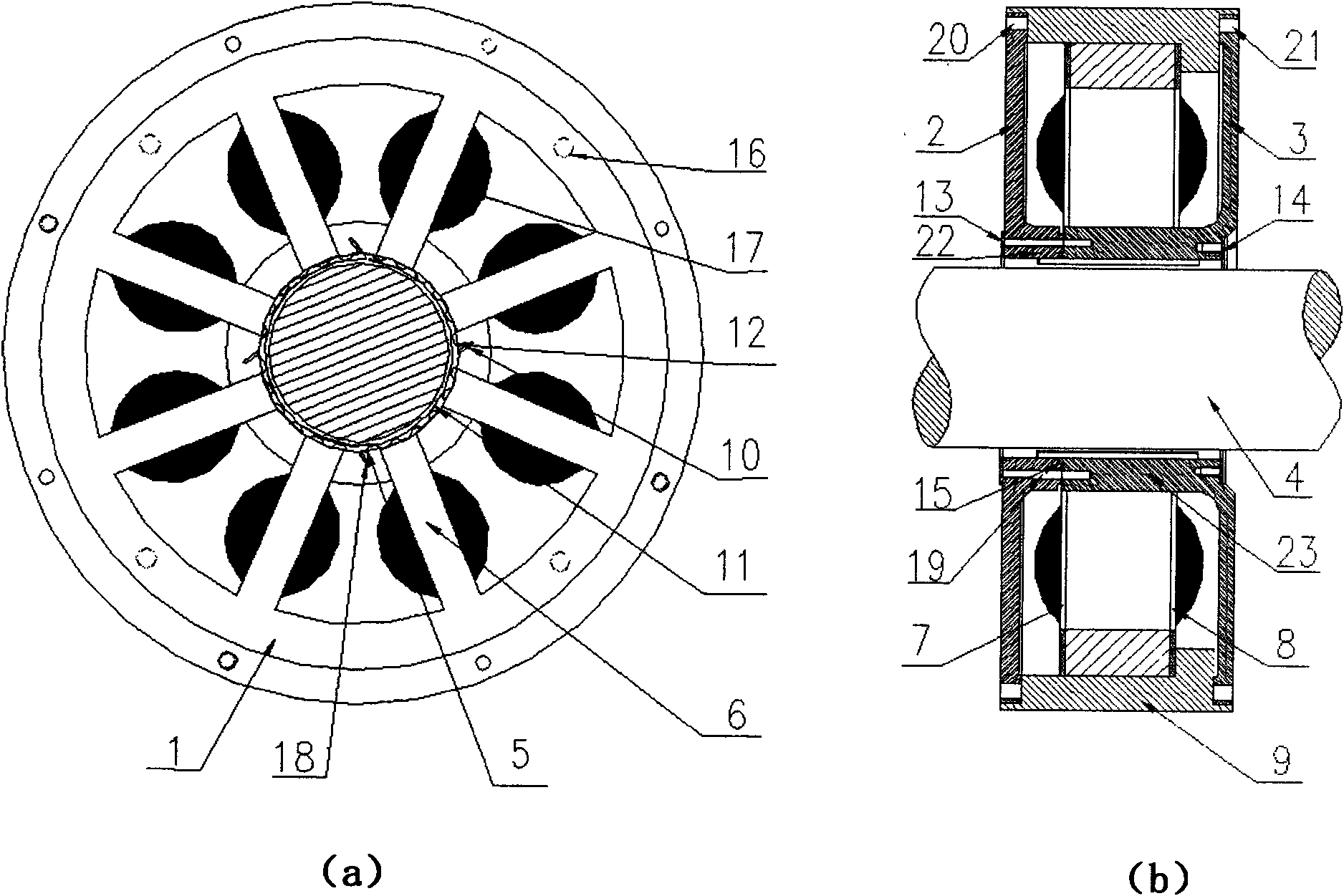

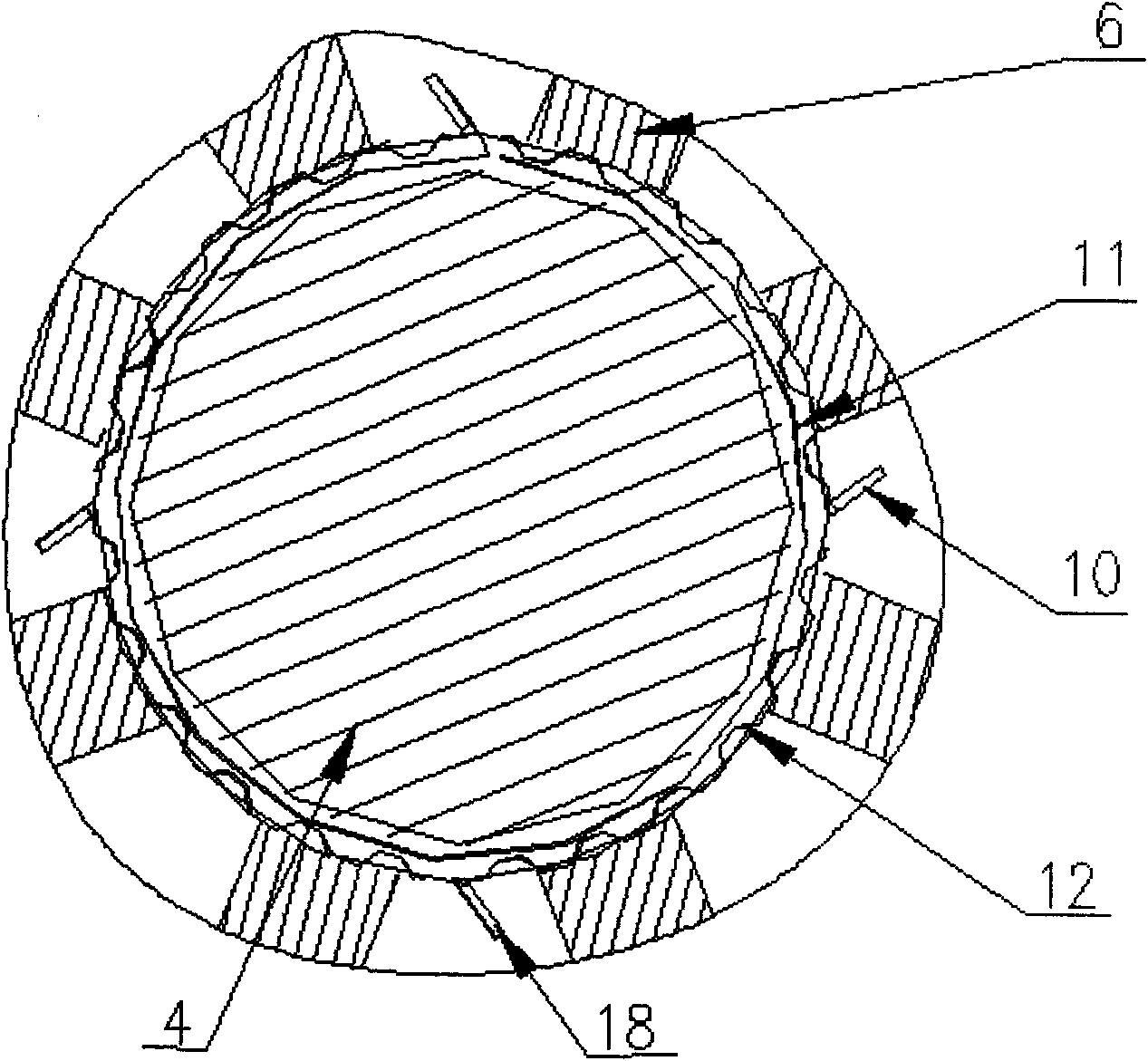

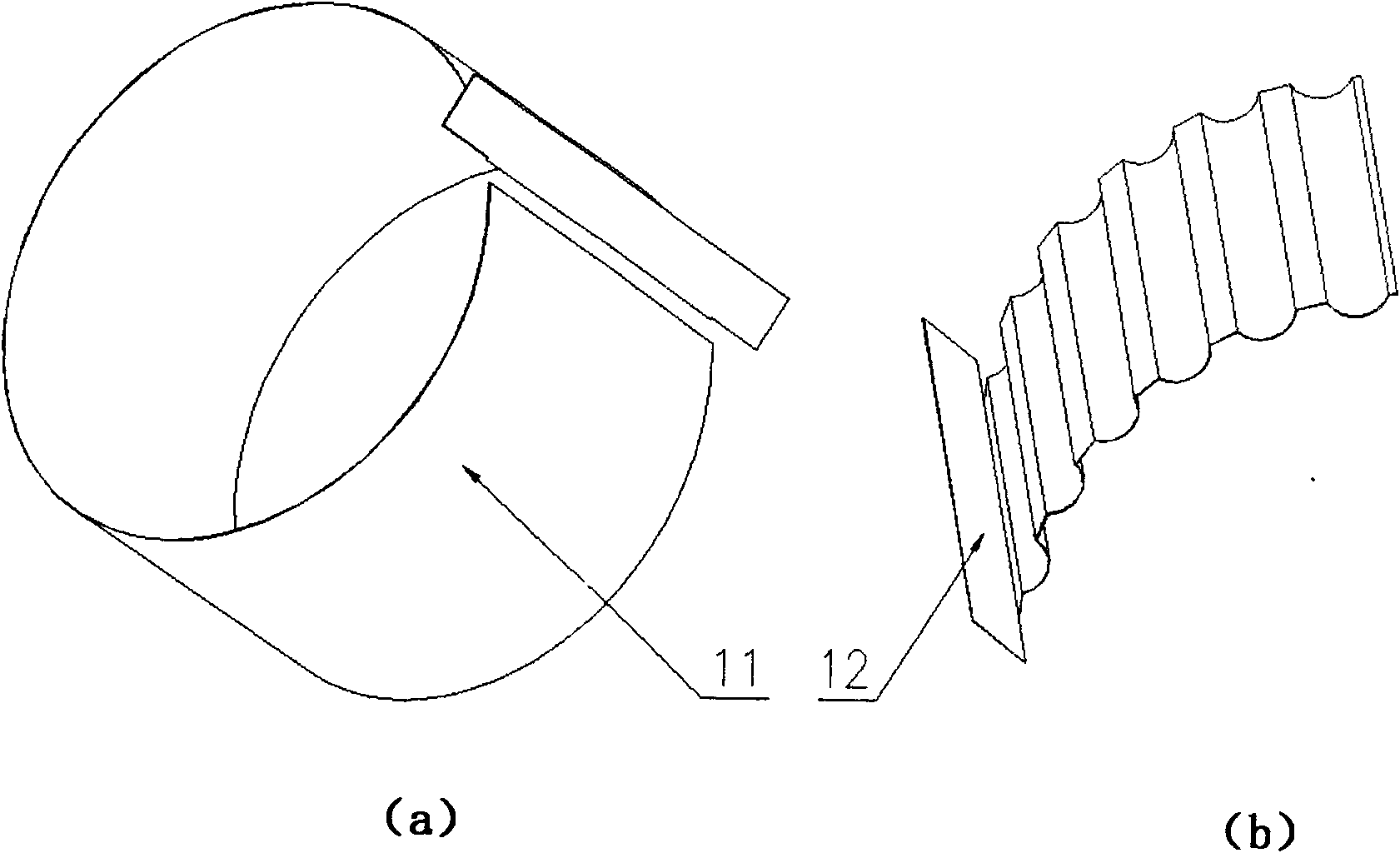

[0025] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] see figure 1 , 2 , 3, 4, 5, 6, a mosaic type electromagnetic-elastic foil gas hybrid bearing, including a bearing base 9, the bearing base 9 is provided with an electromagnetic bearing 1, and the electromagnetic bearing 1 is provided with a left end cover in the axial direction 2 and the right end cover 3, the left end cover 2 and the right end cover 3 are fixed on the bearing base 9 by screws 20 and 21, and an elastic foil bearing 5 is nested between the left end cover 2 and the right end cover 3 and the rotor journal 4, wherein The inner wall of the electromagnetic bearing 1 is provided with n (n=6, 8, 12) magnetic poles 6, and the left retaining ring 7 and the right retaining ring 8 that compress the magnetic pole magnetic piece in the axial direction of the magnetic pole 6 are positioned by the bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com