Method for preserving fresh noodles

A fresh-keeping method and fresh noodle technology, which is applied in food preservation, food preparation, food science, etc., can solve the problems of prolonged production cycle of sterilization process, great damage of chemical preservatives, and inconformity with consumer fashion, etc., and shorten the proofing time , shorten the production cycle, the effect of short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Formula: flour 100kg, purified water 34kg, salt 3kg, compound phosphate 0.4kg, glycerin 3kg, propylene glycol 2kg.

[0022] Processing steps: Weigh the raw and auxiliary materials in proportion to avoid external pollution; dissolve various additives in water and stir evenly, slowly add to the flour, and vacuum the dough for 8 minutes; press it into a 0.5mm thick dough sheet after 20 minutes of airtight proofing, Cut into strips, send them to tunnel-type high-temperature sterilization equipment, and treat them at 110°C for 4.5 minutes; let them stand in a closed sterile environment for 30 minutes, so that the final water content will be controlled at about 25%, and the water activity will be about 0.85; use KPET / PE composite film packaging material, built-in deoxidizer, sealed package, regularly measure the following indicators.

[0023] Sensory indicators: color, smell, tissue state, etc. (such as figure 1 shown);

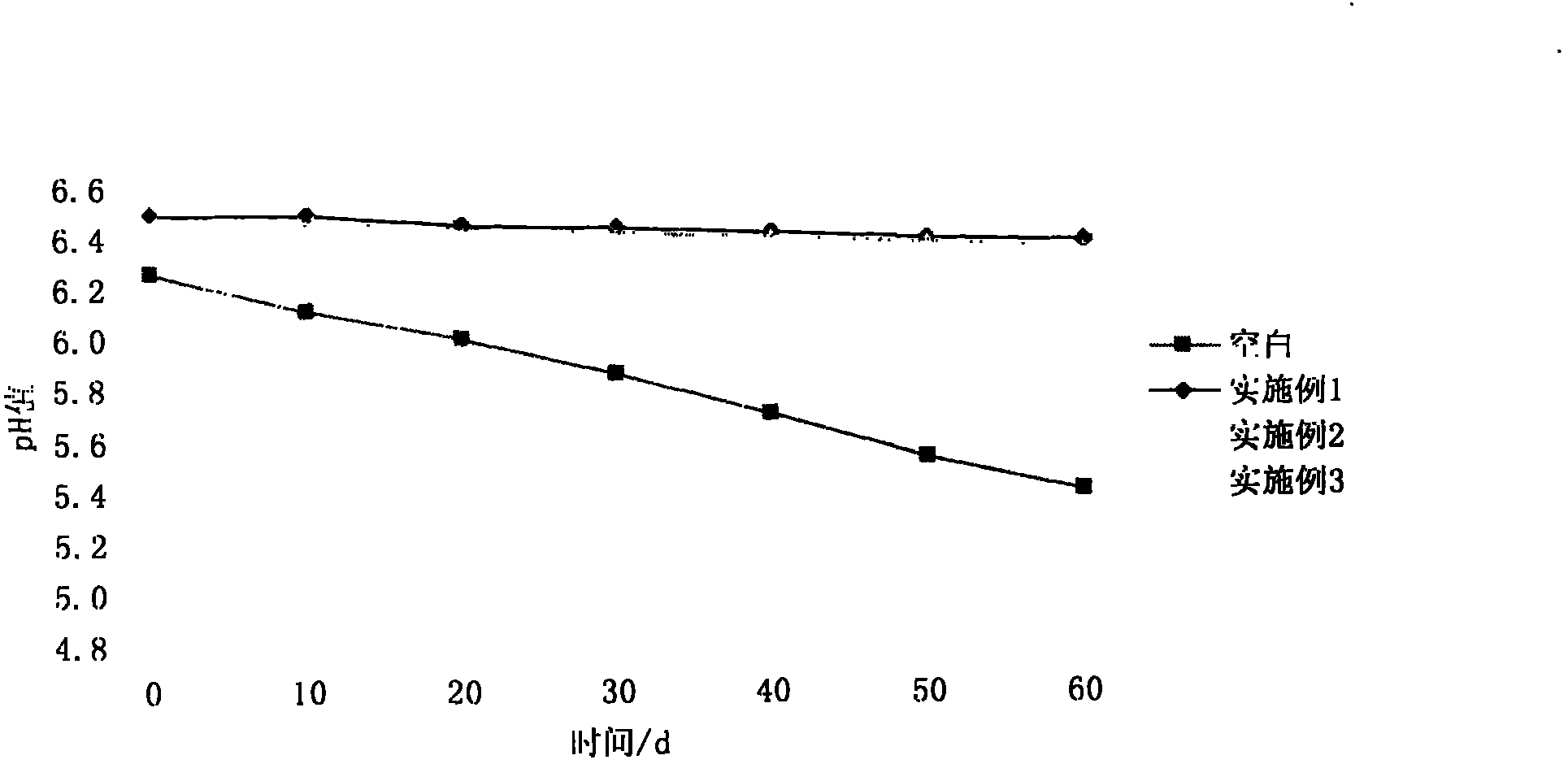

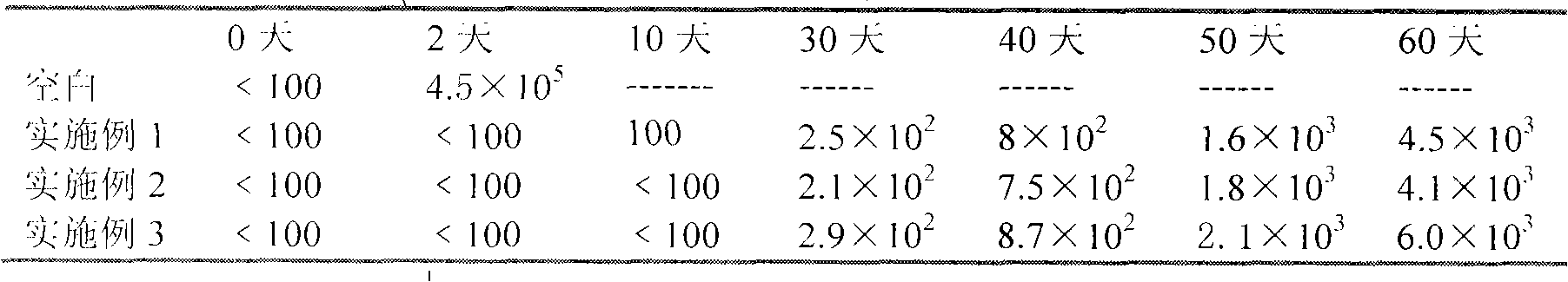

[0024] Physical and chemical indicators: measure it...

Embodiment 2

[0031] Formula: flour 100kg, purified water 38kg, salt 3kg, sorbitol 3kg, glycerin 1kg, compound phosphate 0.8kg.

[0032] Processing steps: Weigh the raw and auxiliary materials in proportion to avoid external pollution; dissolve various additives in water and stir evenly, slowly add to the flour, and vacuum the dough for 8 minutes; press it into a 0.5mm thick dough sheet after 20 minutes of airtight proofing, Cut into strips, send them to tunnel-type high-temperature sterilization equipment, and treat them at 105°C for 8 minutes; let them stand in a closed sterile environment for 30 minutes, so that the final moisture content is controlled at about 20%, and the water activity is about 0.85; KPET / PE is used Composite film packaging materials, built-in deoxidizer, sealed packaging, regularly measure the following indicators.

[0033] Sensory indicators: color, smell, tissue state, etc.

[0034] Physical and chemical indicators: measure its pH value to investigate the degree o...

Embodiment 3

[0038] Formula: flour 100kg, salt 1kg, sorbitol 3kg, propylene glycol 2kg, compound phosphate 0.4kg, purified water 35kg.

[0039]Processing steps: Weigh the raw and auxiliary materials in proportion to avoid external pollution; dissolve various additives in water and stir evenly, slowly add to the flour, and vacuum the dough for 8 minutes; press it into a 0.5mm thick dough sheet after 20 minutes of airtight proofing, Cut into strips, send them to tunnel-type high-temperature sterilization equipment, and treat them at 110°C for 4 minutes; let them stand in a closed sterile environment for 30 minutes, so that the final moisture content is controlled at about 30%, and the water activity is about 0.87; KPET / PE is used Composite film packaging materials, built-in deoxidizer, sealed packaging, regularly measure the following indicators.

[0040] Sensory indicators: color, smell, tissue state, etc.

[0041] Physical and chemical indicators: measure its pH value to investigate the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com