Process for comprehensively treating garbage

A comprehensive treatment and garbage technology, which is applied in the field of garbage treatment technology and comprehensive garbage treatment technology, can solve the problems of low recycling efficiency, increased labor costs, high content of bags, etc., and achieve high dehydration efficiency and low energy consumption for effluent cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

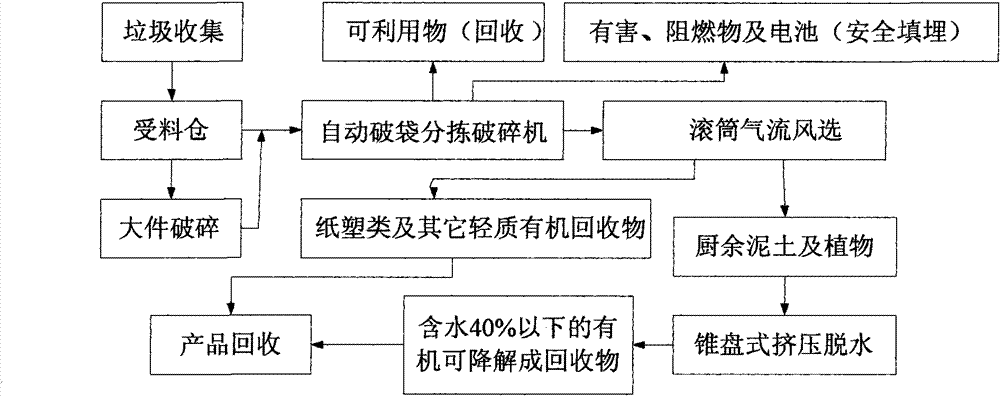

[0031] Embodiment 1, the garbage comprehensive treatment process of this embodiment is a process method for automatic garbage sorting and deep dehydration suitable for the characteristics of high-humidity mixed garbage in China. Through this method, the original garbage can be automatically sorted and deep dehydrated to form Four types of substances:

[0032] 1. Materials with high calorific value and low moisture such as paper and plastic;

[0033] 2. Kitchen waste after deep dehydration and semi-humid substances with a water content of less than 40% after coarse crushing of plants;

[0034] 3. Direct recycling of available quality;

[0035] 4. Inorganic stones, ceramics, rubble, batteries and other backfills.

[0036] The process flow chart of this embodiment is as figure 2 shown, including the following steps:

[0037] Step 1: Automatic sorting and crushing:

[0038] Directly recycle the usable substances in the urban waste, and safely landfill the harmful flame retar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com