Method for preparing carbon-supported high-activity gold or gold-platinum alloy or gold-core platinum-shell structural nano catalyst

A high-activity gold and platinum alloy technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. High rate, simple process, enhanced interaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Catalyst preparation steps are as follows:

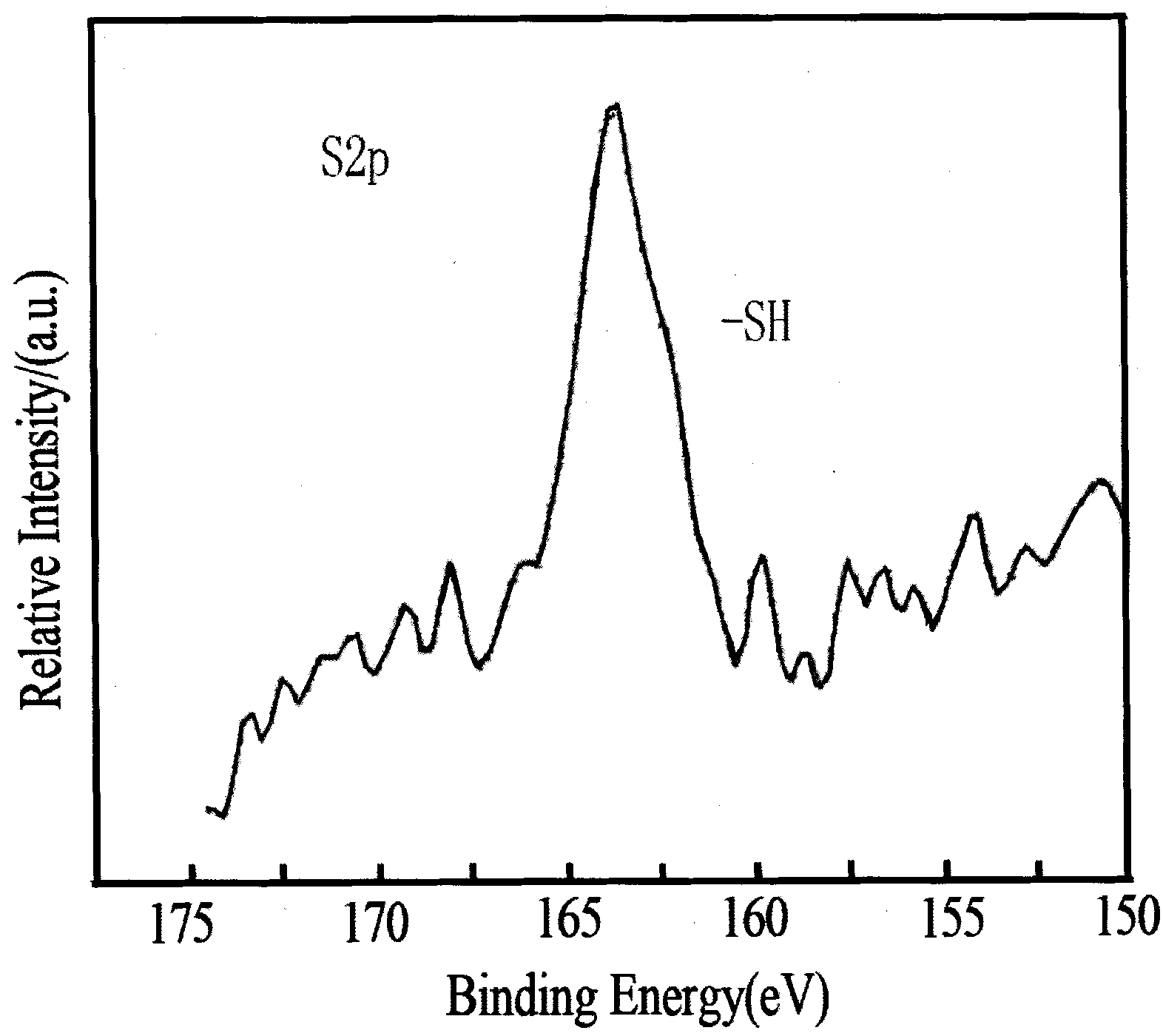

[0029] 1. Add 80ml of absolute ethanol to 0.2g of carbon black, sonicate for 1h, then add 0.2ml of modified chemical reagent thiophenol solution (analytical pure), sonicate for 0.15h, let stand for 10 days, filter, and use 50ml of secondary water After washing and vacuum drying at 60°C for 2 hours, the surface mercaptolated carbon black is obtained.

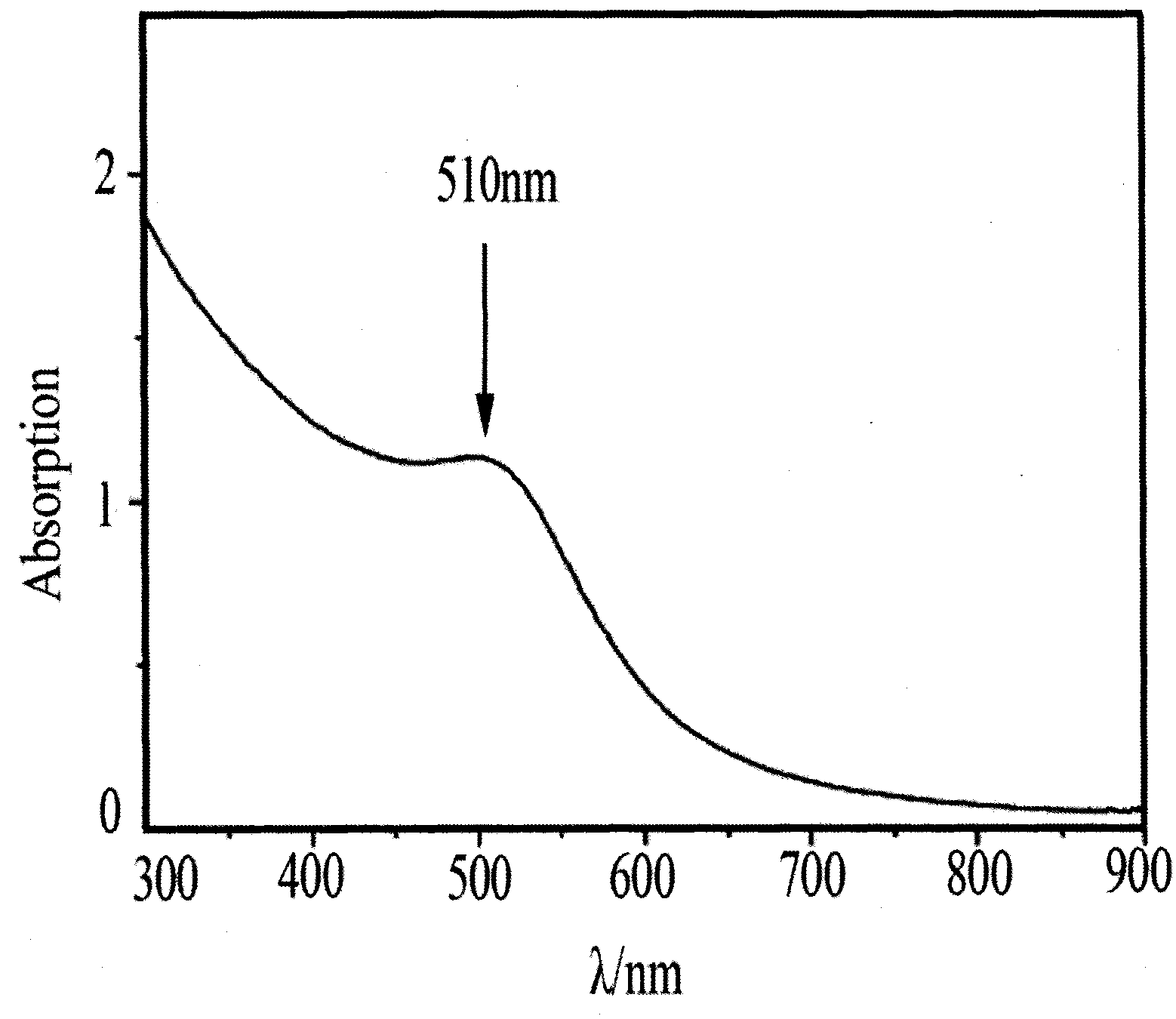

[0030] 2. Take 0.25ml of chloroauric acid aqueous solution with Au(III) content of 2wt%, add water and dilute to 50ml, add 1.5ml of 1wt% polyvinylpyrrolidone as protective agent, then add 2ml of 0.1wt% sodium borohydride as reducing agent , stirred for 0.25h, and the reaction temperature was 10°C to obtain a gold colloidal solution.

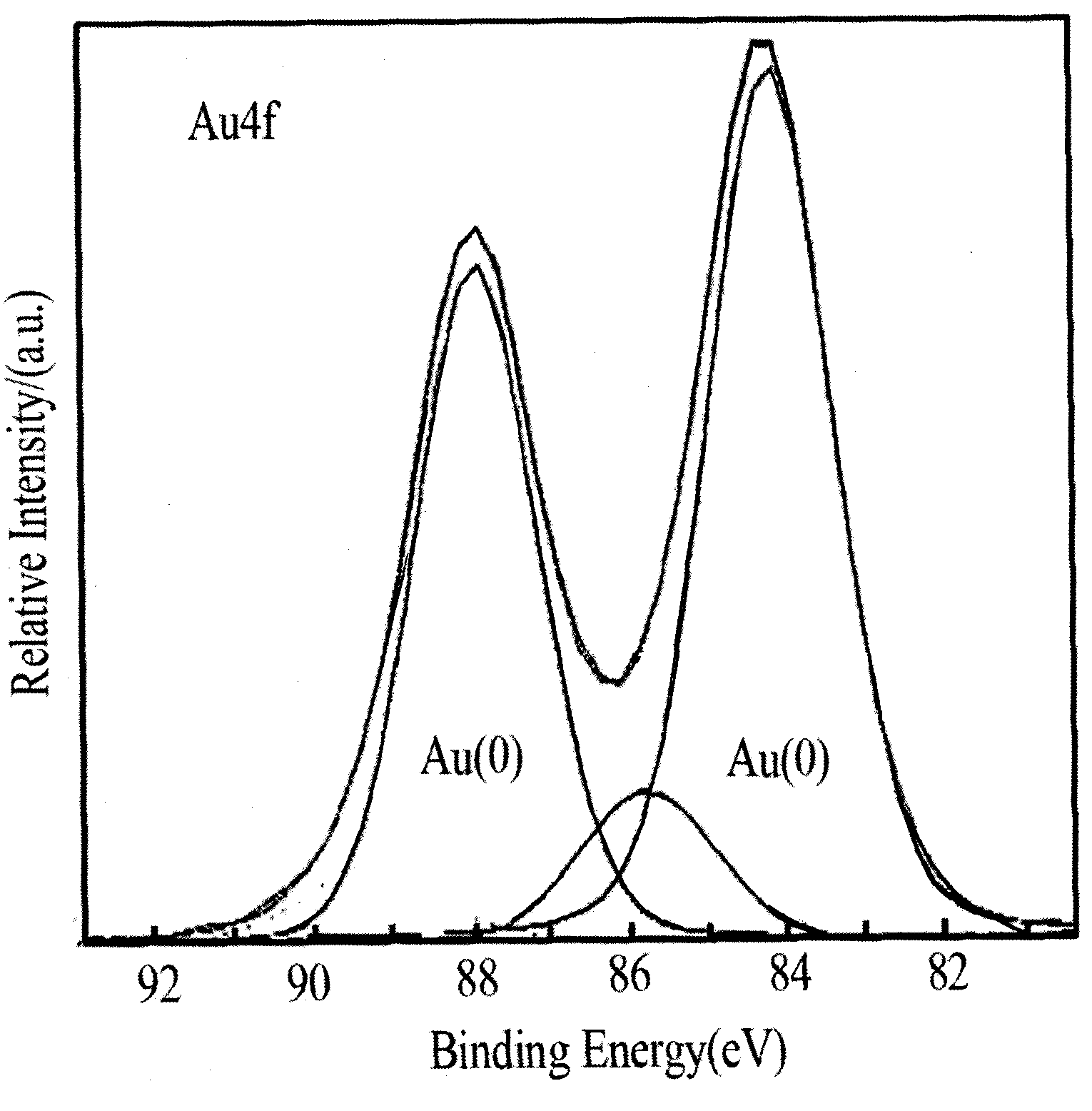

[0031] 3. Add 0.1 g of the carbon black obtained in step 1 to 10 ml of the gold colloid solution in step 2, sonicate for 0.15 h, stir for 24 h, filter, and wash with secondary water until no detectable Cl - , dried at 60° C. for 2 hours to obtain...

Embodiment 2

[0033] Catalyst preparation steps are as follows:

[0034]1. Add 100ml of absolute ethanol to 0.2g of carbon black, sonicate for 1h, then add 0.2ml of modified chemical reagent thiophenol solution (analytical pure), sonicate for 0.15h, let stand for 7 days, filter, and use 50ml of secondary water After washing and vacuum drying at 60°C for 2 hours, the surface mercaptolated carbon black is obtained.

[0035] 2. Take 0.25ml of chloroauric acid aqueous solution with 2wt% Au(III) content and add water to dilute to 50ml, add 1.5ml of 1wt% polyvinylpyrrolidone as protective agent, then add 2ml of 0.1wt% sodium borohydride as reducing agent, After stirring for 0.25 h, the reaction temperature was 25° C. to obtain a gold colloidal solution.

[0036] 3. Weigh 0.005g of the carbon black obtained in step 1 and add it to 33ml of the gold colloid solution in step 2, sonicate for 0.15h, stir for 24h, filter, and wash with secondary water until no detectable Cl - , dried under vacuum at 6...

Embodiment 3

[0038] Catalyst preparation steps are as follows:

[0039] 1. Add 10ml of absolute ethanol to 0.2g of carbon black, sonicate for 1h, then add 0.1ml of modified chemical reagent thiophenol solution (analytical pure), sonicate for 0.15h, let stand for 5 days, filter, and use 50ml of secondary water After washing and vacuum drying at 60°C for 2 hours, the surface mercaptolated carbon black is obtained.

[0040] 2. Get Au(III) content and be that 0.5ml of chloroauric acid aqueous solution of 2wt% adds water and dilutes to 100ml, adds 1% polyvinylpyrrolidone 3ml to make protecting agent, then adds 0.1wt% sodium borohydride 4ml to make reducing agent, After stirring for 0.25 h, the reaction temperature was 30° C. to obtain a gold colloidal solution.

[0041] 3. Add 40ml of the gold colloid solution in step 2 to 0.016g of the carbon black obtained in step 1, sonicate for 0.15h, stir for 24h, filter, and wash with secondary water until no detectable Cl - , dried under vacuum at 60° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com