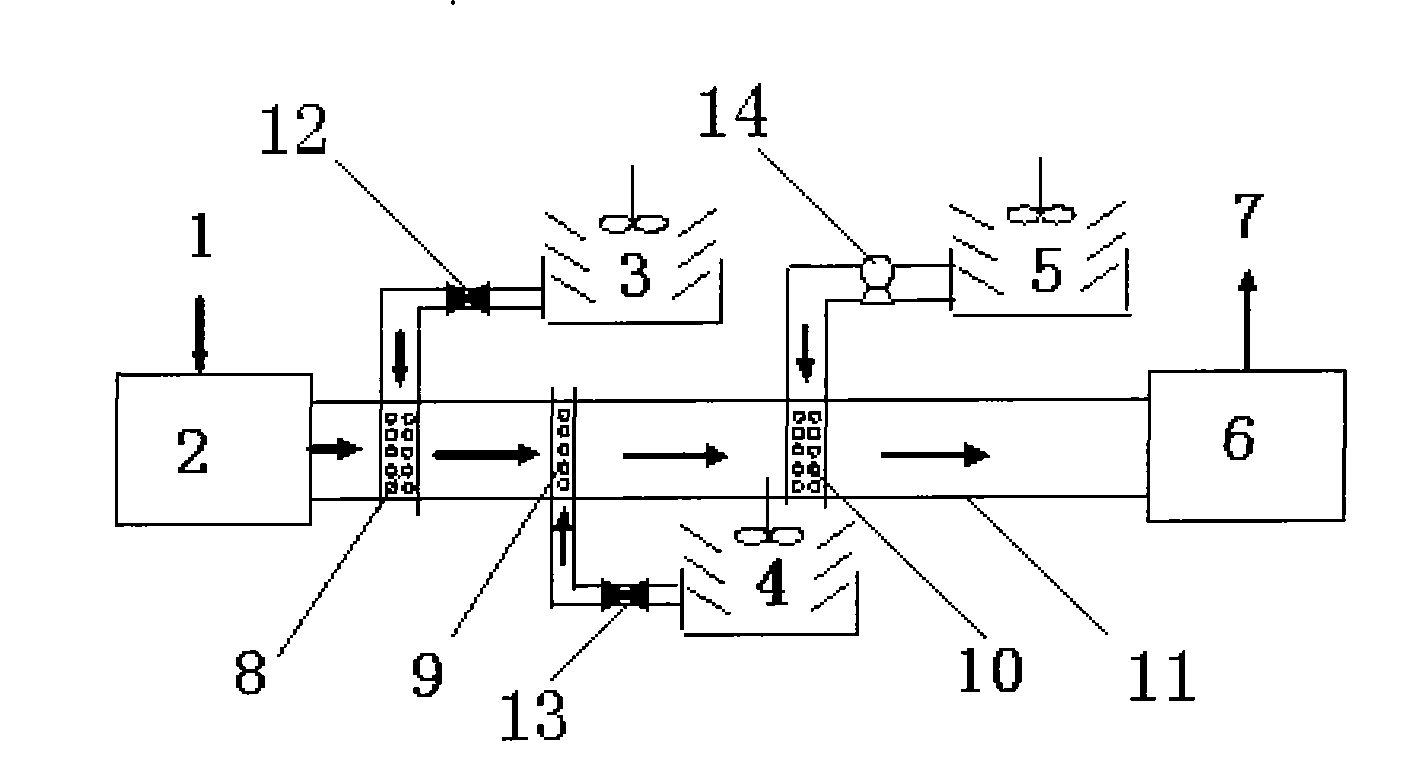

Alkaline printing and dyeing wastewater materialization pretreatment method and system

A printing and dyeing wastewater and pretreatment technology, which is applied in textile industry wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve problems such as difficulty in meeting design requirements, high medicament, high electric energy, and increased unit cost, and achieve Effects of simplifying wastewater treatment process, reducing energy consumption, and reducing biochemical load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

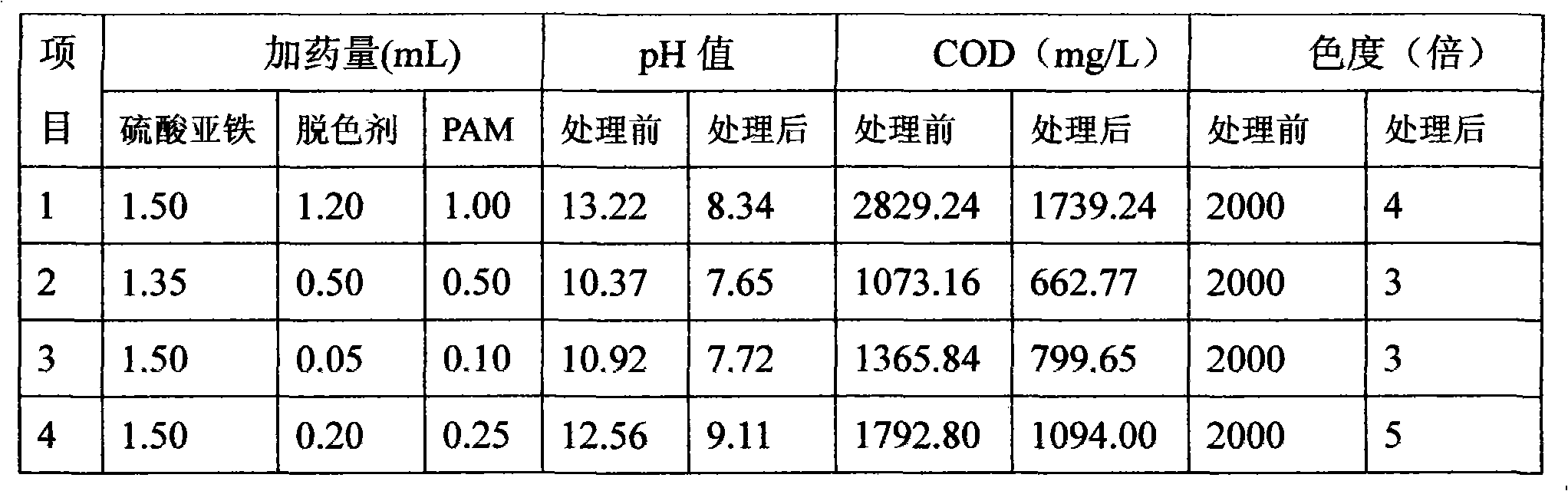

Embodiment 1

[0027] Printing and dyeing wastewater comes from four different production periods of a printing and dyeing factory in Datang Industrial Park, Sanshui District, Foshan City, all of which are dark blue. After measurement, the pH value of the wastewater is 11-13, the COD is 1100-2800mg / L, and the chromaticity is 2000 The specific data is shown in Table 1. Take 100mL of wastewater in each of the four periods, numbered 1, 2, 3 and 4.

[0028] Ferrous sulfate, KW178, anionic polyacrylamide and other reagents are all commercial products.

[0029] Dissolve industrial ferrous sulfate, KW178, and anionic polyacrylamide in water, stir, and prepare the concentration to be 0.25×10 3 g / L, 78.13g / L and 0.41g / L solutions (other concentration experiments will not be repeated here one by one, the method is the same), and then the prepared ferrous sulfate solution is added to the printing and dyeing wastewater, adding an appropriate amount of ferrous sulfate After the solution, adjust the pH v...

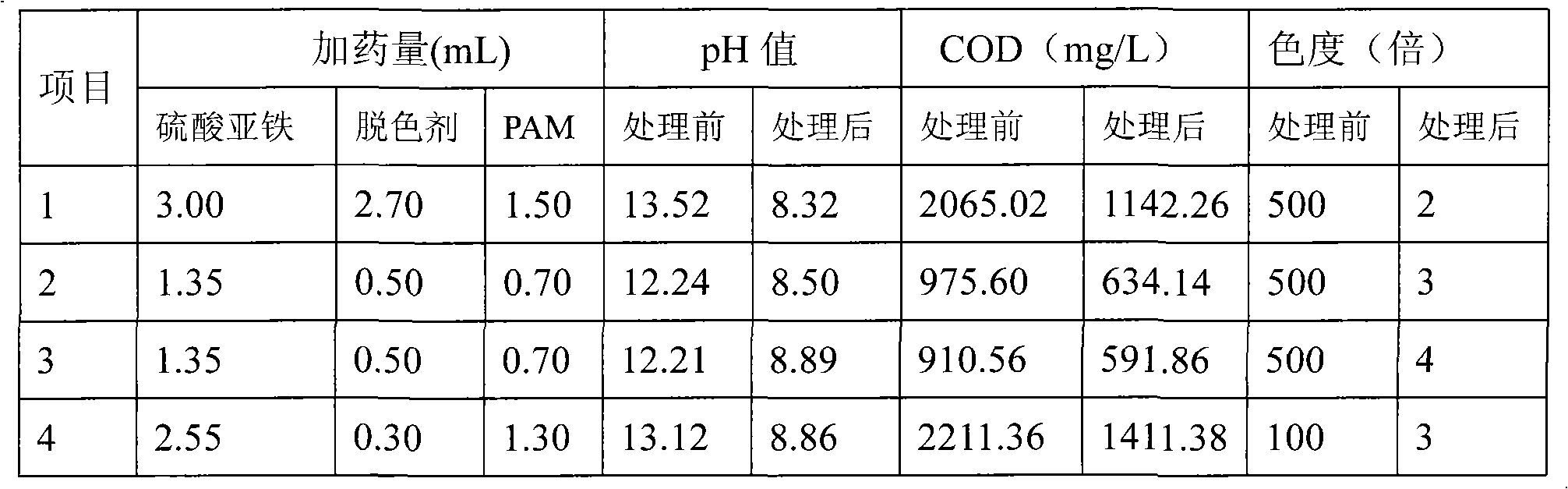

Embodiment 2

[0033] Printing and dyeing wastewater comes from a printing and dyeing factory in Datang Industrial Park, Sanshui District, Foshan City at four different periods of time. About 500 times, the specific data is shown in Table 2, respectively take 100mL of wastewater in each of the four periods, and number 1, 2, 3 and 4.

[0034] Ferrous sulfate, KW178, anionic polyacrylamide and other reagents are all commercial products.

[0035] Dissolve industrial ferrous sulfate, KW178, and anionic polyacrylamide in water, stir, and prepare the concentration to be 0.25×10 3 g / L, 78.13g / L and 0.41g / L solutions, then add the prepared ferrous sulfate solution into the printing and dyeing wastewater, add an appropriate amount of ferrous sulfate solution, and adjust the pH value of the wastewater to 7-9; Add an appropriate amount of 78.13g / L KW178 solution to the printing and dyeing wastewater, and add 0.41g / L anionic polyacrylamide solution after reacting for 2 to 5 minutes. The processing eff...

Embodiment 3

[0040] Printing and dyeing wastewater comes from a dyeing and finishing factory in Datang Industrial Park, Sanshui District, Foshan City. The wastewater is black in four different periods. It will be measured that the pH value of the wastewater is 12-14, the COD is 2200-3000mg / L, and the chromaticity is about 2000 times. , the specific data are shown in Table 3, respectively take 100mL of waste water in each of the four periods, and number 1, 2, 3 and 4.

[0041] Ferrous sulfate, KW178, anionic polyacrylamide and other reagents are all commercial products.

[0042] Dissolve industrial ferrous sulfate, KW178, and anionic polyacrylamide in water, stir, and prepare the concentration to be 0.25×10 3 g / L, 78.13g / L and 0.41g / L solutions, and then add the prepared ferrous sulfate solution into the printing and dyeing wastewater, after adding an appropriate amount of ferrous sulfate solution, the pH value of the wastewater is adjusted to 7-9; Add an appropriate amount of 78.13g / L KW1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com