Waterproof and crack-resistant dry-mixed mortar of steel slag sand

A dry-mixed mortar, steel slag sand technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., to achieve stable performance, simple construction, excellent impact resistance and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

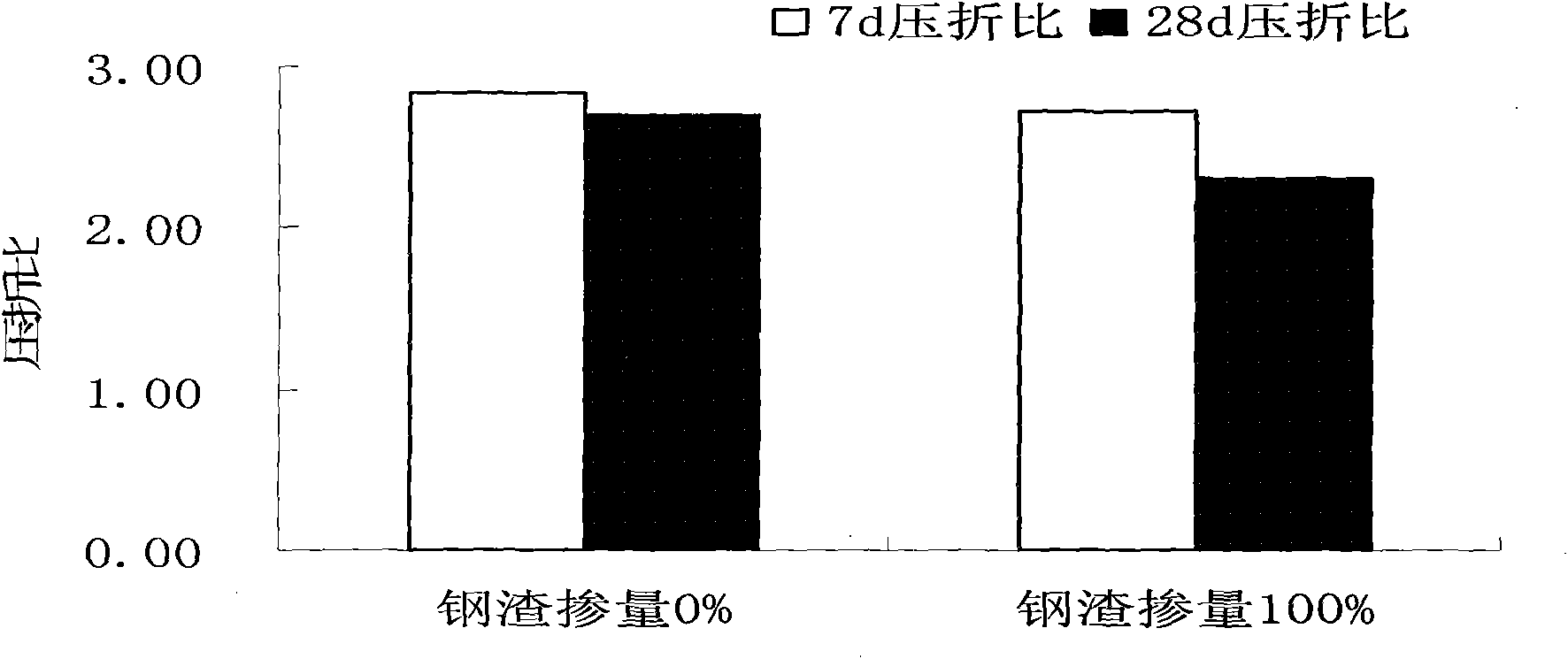

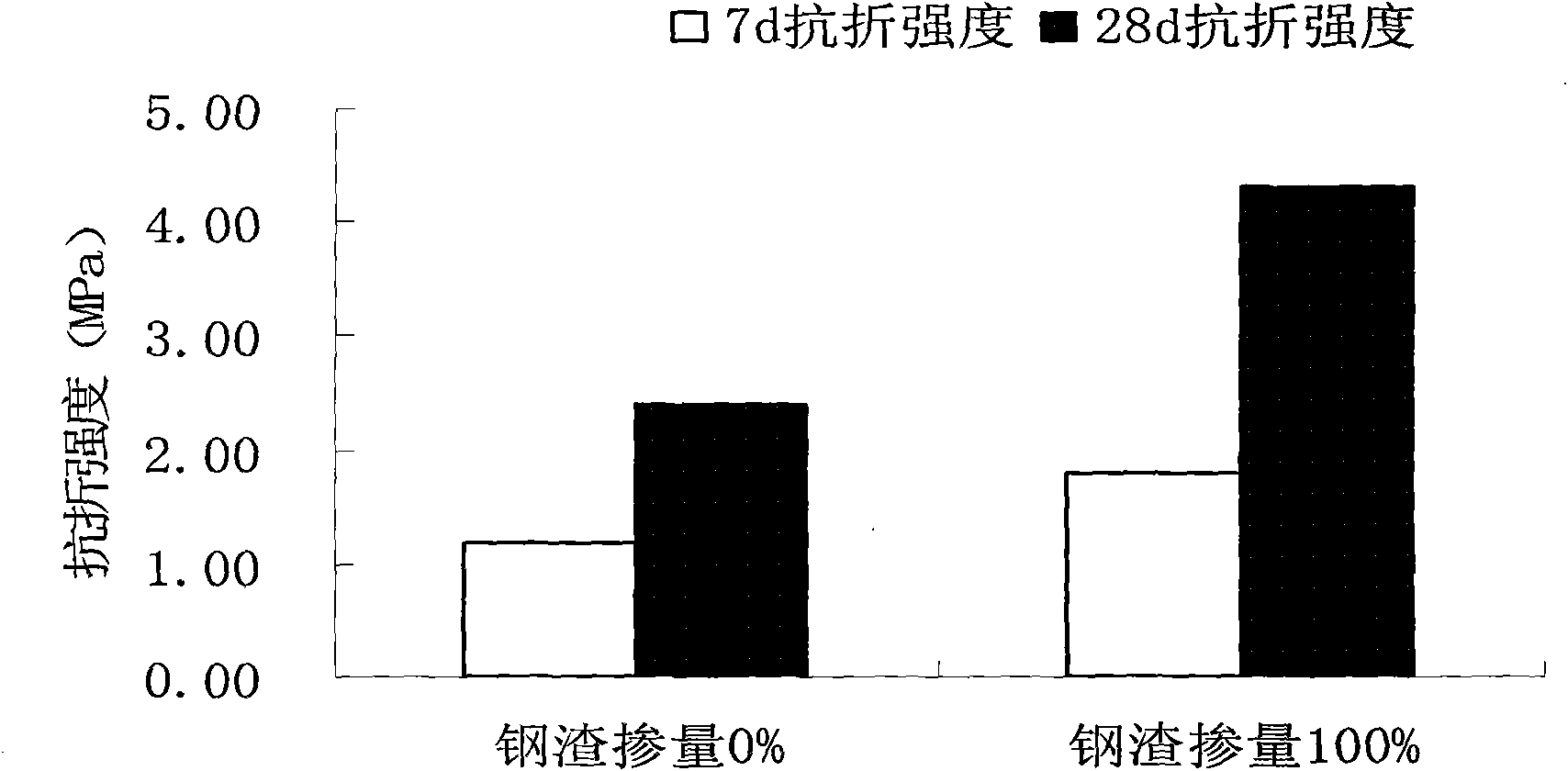

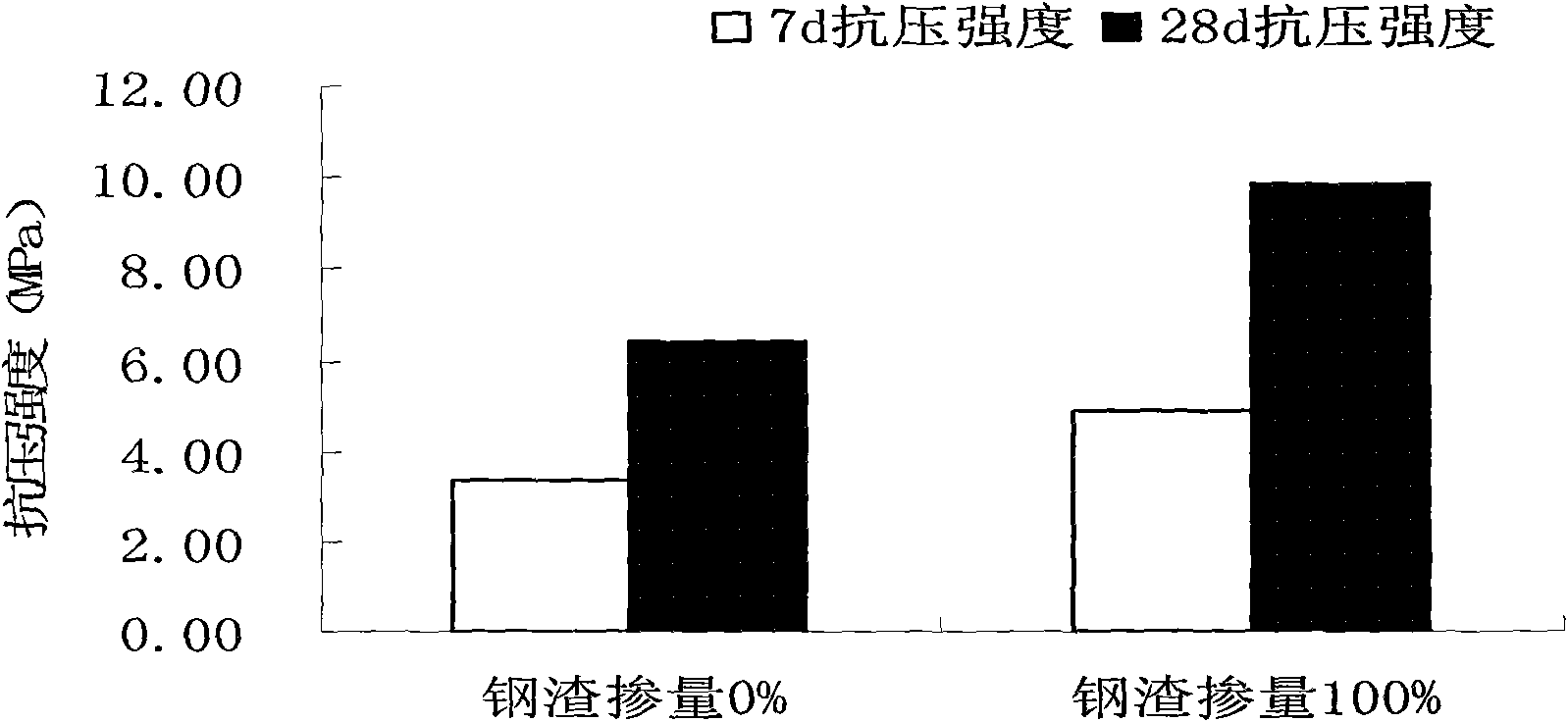

[0034] Steel slag sand waterproof and anti-cracking dry-mix mortar, its components and weight percentage: steel slag with particle size ≤0.6mm: 55%, fly ash portland cement: 40%, acrylic rubber powder: 4%, Wenlun glue water retaining agent : 0.01%, wood fiber: 0.1%, water reducing agent: 0.5%, silicone waterproofing agent: 0.3%.

Embodiment 2

[0036] Steel slag sand waterproof anti-cracking dry-mix mortar, its components and weight percentage: steel slag with particle size ≤0.3mm: 45%, natural sand 15%, slag portland cement: 36%, acrylic rubber powder: 3%, cellulose Ether water retaining agent: 0.2%, wood fiber: 0.3%, water reducing agent: 0%, silicone water repellent: 0.5%.

Embodiment 3

[0038] Steel slag sand waterproof and anti-cracking dry-mix mortar, its components and weight percentage: steel slag with particle size ≤0.5mm: 75%, ordinary portland cement: 22%, acrylic rubber powder: 1.4%, water reducer: 0.5%, Wood fiber: 1.0%, Wenlun glue water retaining agent: 0.1%, silicone water repellent: 0%.

[0039] Preparation of steel slag sand waterproof and anti-crack dry-mix mortar for transportation, railway and underground waterproofing:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com