Impermeable concrete and preparation method thereof

A technology of impervious concrete and machine-made sand, which is applied in the field of concrete, can solve the problems of shortening the service life of concrete buildings, difficulty in controlling the expansion rate of expansion agents, and increasing maintenance costs of concrete buildings, so as to improve impermeability and crack resistance, Improve compactness, improve the effect of anti-crack and anti-seepage ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

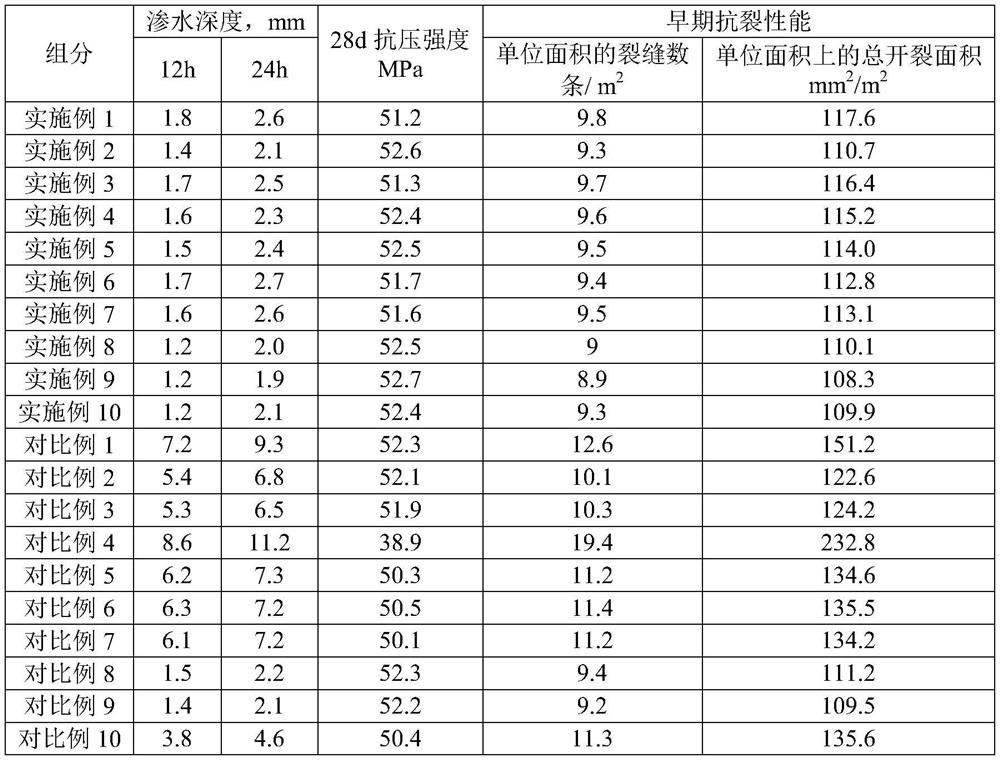

Examples

Embodiment Construction

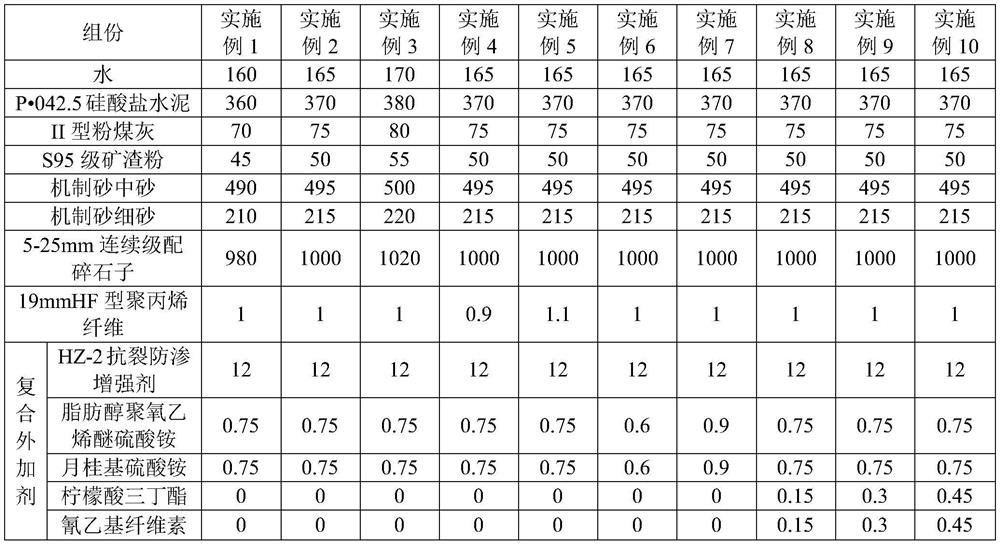

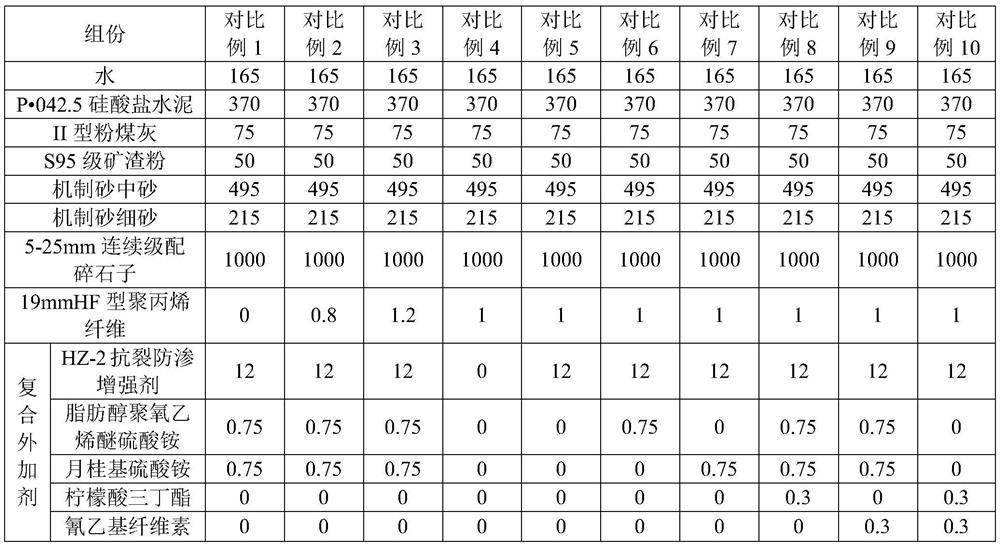

[0037] The present application will be described in further detail below in conjunction with the examples.

[0038] Table 1 source of raw materials

[0039] raw material Manufacturer cement Tangshan Jinma Qixin Cement Co., Ltd. fly ash Tianjin Guohua Panshan Power Generation Co., Ltd. Slag powder Tangshan Ganglu Iron and Steel Co., Ltd. fiber Baoding Mingcheng Hengyuan Building Materials Sales Co., Ltd. sand in mechanism sand Xinglong Chengtai Building Materials Co., Ltd. Mechanism sand fine sand Xinglong Chengtai Building Materials Co., Ltd. pebbles Xinglong Chengtai Building Materials Co., Ltd. Anti-crack and anti-seepage enhancer Hebei Hezhong Building Materials Co., Ltd. Fatty alcohol polyoxyethylene ether ammonium sulfate Xingtai Xinlanxing Technology Co., Ltd. ammonium lauryl sulfate Linyi Lvsen Chemical Co., Ltd. tributyl citrate Shandong Jichuang Chemical Co., Ltd. Cyanoethyl Cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com