Application of carbazole oxime ester compound serving as photoinitiator in photopolymerisable acrylate composition

An acrylate and acrylate technology, used in optics, optical filters, optomechanical equipment, etc., can solve the problem of poor specific selectivity of photopolymerizable monomers, high transparency and photolithography residues, and insufficient short-wavelength sensitivity. problem, to achieve excellent curing effect, high short-wavelength sensitivity, and no scum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0038] (1) Colored curable (photopolymerizable) composition No. 1-1

[0039] Colorant (carbon black) 300 parts by mass

[0040] 200 parts by mass of alkali-soluble resin

[0041] (Benzyl methacrylate / methacrylic acid / hydroxyethyl methacrylate (70 / 10 / 20 molar ratio) copolymer (Mw: 10,000))

[0042] 100 parts by mass of dipentaerythritol hexaacrylate

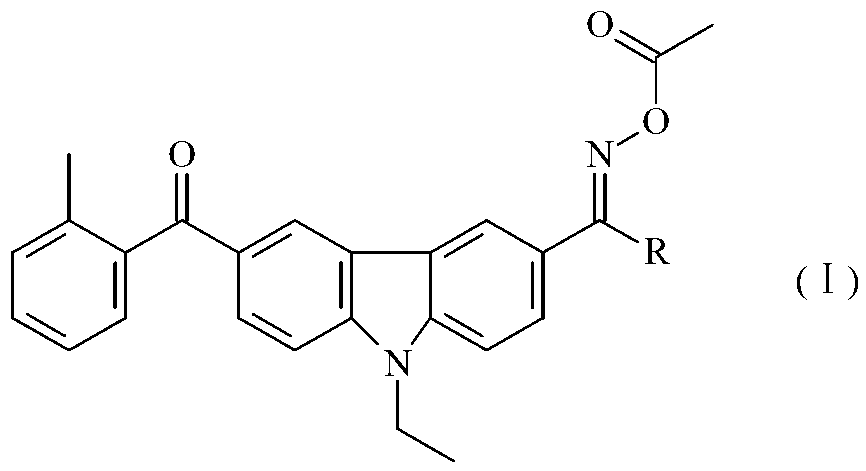

[0043] Formula (I) oxime ester compound [n=2, m=3] 60 parts by mass

[0044] Surfactant FC-4430 1 part by mass

[0045] (2) Preparation of filter color film

[0046] The components of the above composition were mixed and dissolved in 1000 parts by mass of a solvent, propylene glycol methyl ether acetate (PGMEA), to form a liquid composition.

[0047] Use a spin coater to coat the liquid composition on a glass substrate, dry it at 90°C for 2 minutes, and form a coating film with a film thickness of 1.5 μm; in order to obtain a coating film with the above thickness, the coating process can be completed once or Do it multiple t...

Embodiment 1-2

[0074] Use the formula (I) oxime ester compound of n=2, m=4 to replace the oxime ester compound in embodiment 1-1, other unchanged, prepare in the same way, and with the same method of embodiment 1-1 method to evaluate. The results are shown in Table 1.

Embodiment 2-1

[0082] (1) Colored curable composition No.2-1

[0083] Colorant C.I. Pigment Red 254 60 parts by mass

[0084] 80 parts by mass of alkali-soluble resin

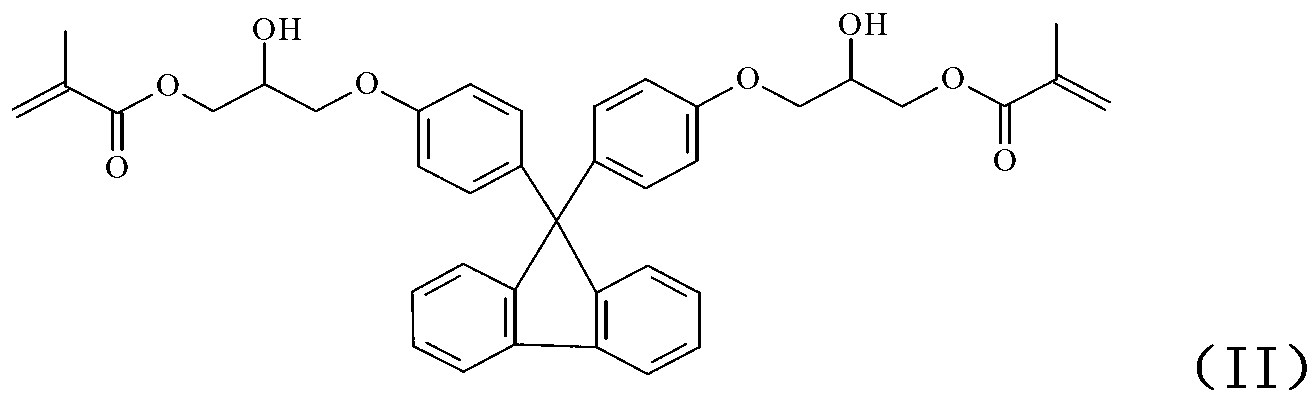

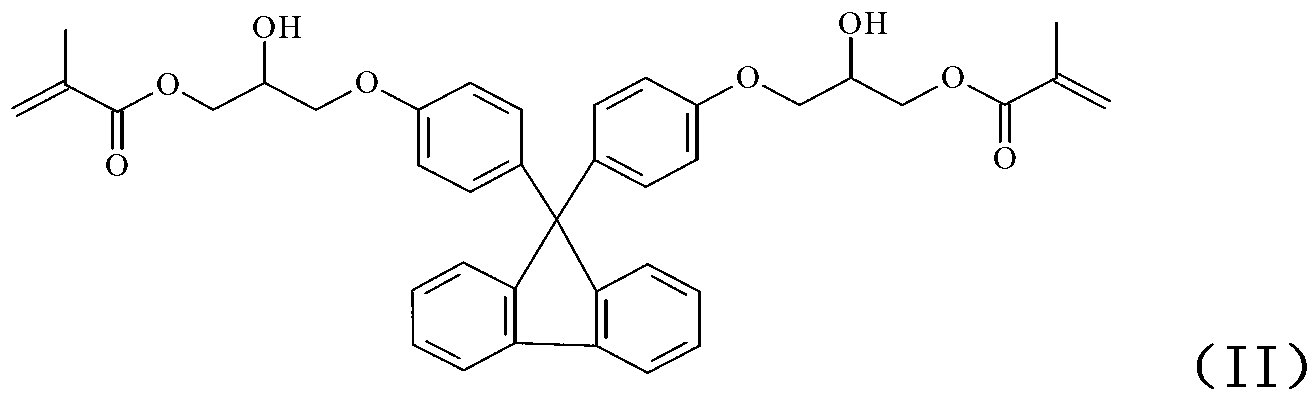

[0085] [Benzyl methacrylate / methacrylic acid / hydroxyethyl methacrylate / acrylic ester of formula (II) (55 / 10 / 15 / 10 in molar ratio) copolymer] (Mw: 12,000)

[0086] 35 parts by mass of dipentaerythritol hexaacrylate

[0087] Formula (I) oxime ester compound [n=2, m=3] 20 parts by mass

[0088] Surfactant FC-4430 0.1 parts by mass

[0089] (2) Preparation of filter color film

[0090] The components of the above composition were mixed and dissolved in 100 parts by mass of a solvent, propylene glycol methyl ether acetate (PGMEA), to form a liquid composition.

[0091] Use a spin coater to coat the liquid composition on a glass substrate, dry it at 90°C for 2 minutes, and form a coating film with a film thickness of 1.5 μm; in order to obtain a coating film with the above thickness, the coating process can be completed once o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com