Method for preparing phase change thermal insulation polyurethane resin

A polyurethane resin and phase change technology, applied in the field of preparation of functional polymer materials, can solve problems such as poor mechanical properties, and achieve the effects of excellent phase change thermal insulation performance, good mechanical properties and environmental responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

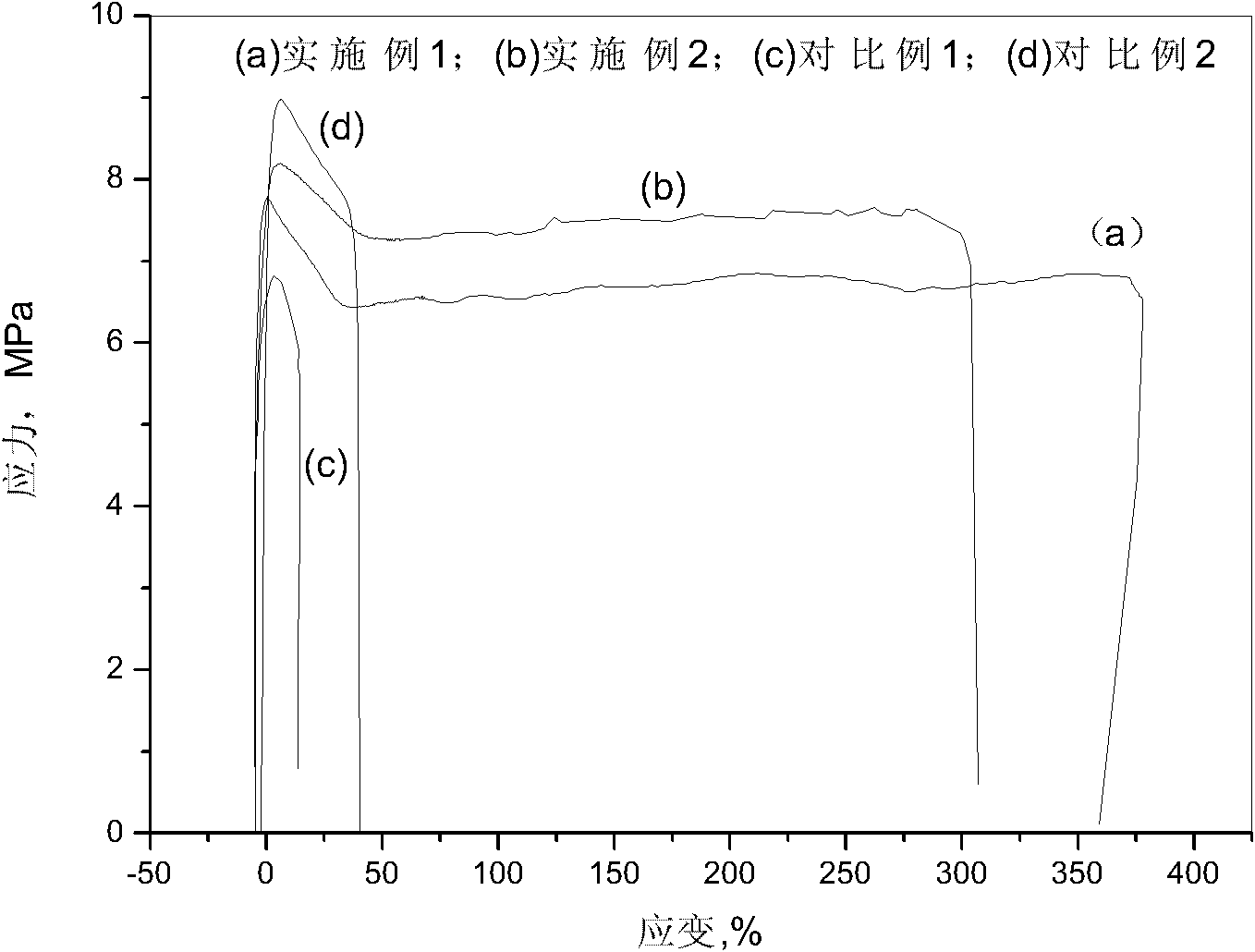

[0027] Embodiment 1 (chain extender is 1,4-dihydroxyethyl-3-methylureidopyrimidinone)

[0028] 20g of dehydrated polyethylene glycol with a molecular weight of 10000 was dissolved in 60ml of N,N-dimethylformamide, 0.672g of 1,6-hexamethylene diisocyanate and 0.05g of dibutyltin dilaurate were mixed in the reactor After uniformity, pre-polymerize at 80°C for 3 hours under the protection of nitrogen; then add 0.512g of the previously synthesized chain extender 1,4-dihydroxyethyl-3-methylureidopyrimidinone, and continue to expand at 80°C under the protection of nitrogen. chain reaction for 5 hours, then poured into a mold, placed in a blast oven at 70°C for 12 hours to remove the organic solvent, and obtained a phase-change thermal insulation polyurethane resin.

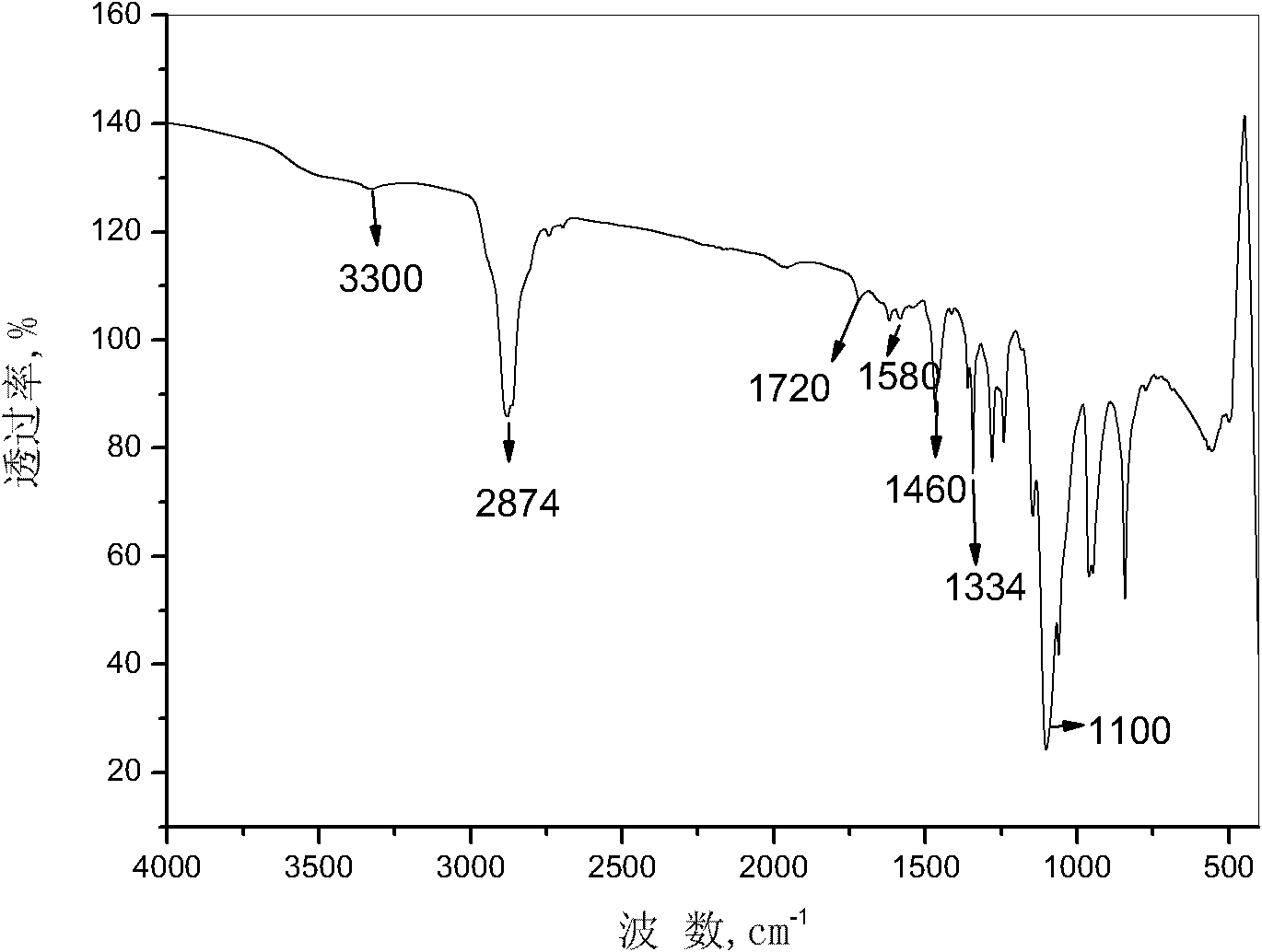

[0029] The infrared spectrum of the phase-change thermal insulation polyurethane resin is as follows: figure 1 shown, from figure 1 It can be seen that the polyurethane prepolymer has been successfully chain-extended ...

Embodiment 2

[0032] Embodiment 2 (chain extender is 1-aminohexyl-3-methyl-4-aminoethylureidopyrimidinone)

[0033] 20g of dehydrated polyethylene glycol with a molecular weight of 10000 was dissolved in 60ml of N,N-dimethylformamide, 0.672g of 1,6-hexamethylene diisocyanate and 0.05g of dibutyltin dilaurate were mixed in the reactor After uniformity, pre-polymerize at 80°C for 3 hours under the protection of nitrogen; then add 0.508g of the previously synthesized chain extender 1-aminohexyl-3-methyl-4-aminoethylureidopyrimidinone, and still under the protection of nitrogen for 80 ℃ chain extension reaction for 5 hours, then poured into a mold, and placed in a blast oven at 70 ℃ for 12 hours to remove the organic solvent to obtain a phase-change thermal insulation polyurethane resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com